8 minute read

Robotic mowing

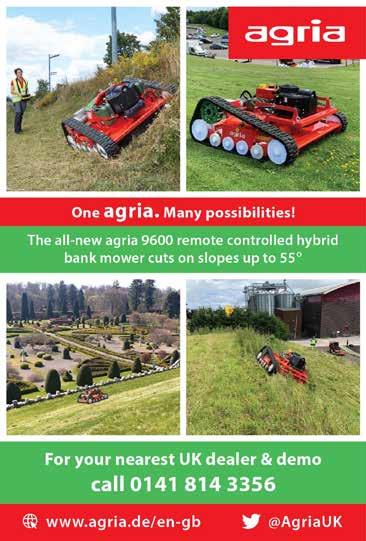

Meet the super smart agria 9600

This season Wiedenmann UK dealers launched the new look agria 9600 remote controlled banks mower for steep slopes up to 55°. Engineering and software enhancements to the rotary mulching mower have made it smarter and more effective.

Advertisement

Wiedenmann UK’s lead demonstrator, Andy Kerr, carries out installation and training across the country, and knows the upgraded machine well.

“The original 9600 was pretty special but by introducing smart technology, it’s been future proofed,” he said.

“You can’t help but notice even more Health & Safety benefits. For contractors, local authorities and Course Managers this is exactly what they want. Staff risk is minimised because the operator can take a safe position up to 100 metres away.

“The 2021 version has a heavier duty design – thicker steel on the undercarriage makes it sturdier and while caterpillar tracks come as standard, optional tracks with cleats can now be purchased for challenging conditions and all weathers.

“The electric motors and generator are more powerful and brushless. Stronger and greased seal bearings have been introduced while the V-belt now tensions automatically. The brushless generator requires zero maintenance so instantly it is more reliable. Brushless drive motors also mean there is no need for 1000 hours replacement. The net result is a more precise fluent feel. “Extra smart technology has been introduced inside the control box where the electronics are protected from dust, vibration and moisture. Sensor technology intervenes in critical circumstances by alerting the operator to hidden or harmful objects such as stones and shuts down immediately. A tilt sensor will also shut down the machine if the control pad is dropped, or the operator stumbles, or if no motion is felt for three seconds.

“For me the introduction of an optional telematics pack with GPS takes it to a great new level. Amazingly it self-diagnoses issues before they happen. How cool is that? When you take the machine back to its parking bay you keep the ignition on for 15 minutes to download historic data.

The agria 9600 cuts and mulches in two directions and is effortless on a variety of applications, including fine turf, while offering an even faster way to adjust cutting height to between 50 -185 mm.

Innovative ‘electric hybrid drive’ allows the agria 9600 to be more efficient and environmentally friendly than other hydraulic concepts. Safety Extra Low Voltage (48V) electricity is generated as the petrol engine drives the mower blades and generator. Accordingly, the maintenance-free motors convert the current into powering the tracks. A replacement fuel cannister system makes refuelling safe and easy, even on difficult terrain. Two standard 10 litre cannisters can be easily removed and reconnected.

www.agria.de/en-gb/ @AgriaUK

To boldly go where it’s just too difficult

Do you want to mow where even walking is difficult? A remote control mower is the ideal solution.

Too often there are difficult to reach areas that require mowing but are very unpleasant or unsafe for the operator. Such environments include steep ground, loose substrate, mowing under trees and shrubbery, along hedge rows, through stinging nettles, high grass and even areas around wasp nests.

Ride-On Solution: The specialist job of mowing on steep and difficult terrain has always been a challenge for the machine operator, with their safety a primary concern. The AS Motor AS 940 4WD remote control mower has been specifically developed for this demanding application. It is the world’s first rideon mower that can easily and quickly convert from a ride-on brushcutter into a remote control mower.

It offers a 90cm cutting deck, with a 27hp Briggs & Stratton engine, 4wd, limited-slip differential and a cross blade and the AS 940 remote control mower mows with ease dense, high grass and undergrowth up to 1.5m in height on terrain where other mowers would have been forced to give up.

Walk-Behind: There are 2 models available from award winning German manufacturer Koppl;

Taurus – this is a versatile remote controlled and walk-behind mower offering a high performing, robust solution for heavy use in tough working conditions and areas that are difficult to access.

The Taurus adjusts perfectly to the height of the operator and the handlebars can be adjusted and swivelled by 180° without tools using the quick-release lever. In addition, the handlebar can be offset to the left and right by 20° so that the operator can walk comfortably next to the machine while still retaining full control.

Crawler – work safety, flexibility, short set-up times and working comfort – these were the main goals in the development of the Köppl Crawler (tracks). The machine with 23hp power and hydraulic drive is extremely compact, manoeuvrable and predestined for work on slopes as well as in difficult to reach places.

The Crawler’s high gradeability and load-bearing capacity also allow it to be used for steep slopes up to a slope angle of 120%.

The remote control with a range of 300m makes it possible to handle the Crawler comfortably and expertly from a distance. n www.psdgroundscare.co.uk

Making better use of volunteers

With a large football pitch to maintain, Aylesbury Vale Dynamos, with 32 teams under its belt, has turned its attention to autonomous mowing, to help the growing club maintain its vast football pitch. Crediting Husqvarna Automower Club Solution, the club has noted great benefits of Automower, in just three months.

The club’s Chairman, Mike Borrett, discussed moving to Husqvarna Automower Club Solution, following a recommendation from Farol Ltd, which is a specialist dealer with a dedicated Automower sales and installation team. Their recommendation would allow two Automower 550 to work simultaneously alongside each other, now using just one boundary wire.

Aylesbury Vale Dynamos relies heavily on volunteers to help run the club, which has always brought about its own set of challenges, including limited time, resource and finance.

“Making the move to Automower has been a brilliant decision for the club, that has paid off multiple times over. Following discussions with Husqvarna and our Automower dealer, Farol Ltd, it quickly became evident that Automower Club Solution could solve many of the challenges we were facing,” said Mike

“We’re incredibly grateful to all our volunteers, but it does provide its own set of challenges. Whether it’s raining or beaming with sunshine, the grass requires twice-weekly cutting, and if no one is able to do it, we end up with grass that’s too long and debris on the pitch, both of which cause problems when the teams go out to play.

“Thanks to Automower we’re able to redeploy our volunteers to more skilful tasks, saving ourselves hours of time each week, and with them being battery powered, we’ve also been able to eliminate the need for petrol, which has been great for reducing our CO2 emissions, and the club’s finances.”

Ever since the first Automower was introduced in 1995, Husqvarna has been known as the world leader in robotic mowing. With over 2 million sold worldwide, Automower is renowned for its low energy consumption, zero emissions, low noise and high productivity, whilst featuring the ability to withstand a busy match schedule and hours of intense training.

As Automower cuts the grass every day, the impact on the turf and ground is minimal. The very small, quick-composting clippings provide a constant source of fertilisation and moisture, creating greener and denser turf. Research also shows that the constant cutting allows grass roots to grow 25% deeper, resulting in a healthier and stronger pitch.

Mike discussed the club’s use of Club Solution: “Automower Club Solution has continuously impressed us with its innovation. The system has allowed our two 550 mowers to be used simultaneously on one pitch, without wires intersecting the playing surface.”

With Automower Club Solution, two or three mowers are able to mow the pitch simultaneously, with only a single boundary wire outside the playing surface, eliminating the risk of a damaged boundary wire during turf treatment such as aeration or scarification.

“The Dynamo’s team are big fans of the mowers, naming them ‘Dyna’ and ‘Mo’, and the fans are even more so. Each match spectators ask us about them, and we can’t blame them, they really are fascinating, and we can’t imagine switching back to manual stadium mowing.” n www.husqvarna.com/uk/

products/robotic-lawn-mowers/

New products from Irus Machinery

German based Irus Machinery have launched a new range, based on the original concept of high power low weight and superior stability.

Taking the tried and tested Deltrak series it now has improved chassis design, an increase in power to 61 hp, 80 litres/min hydraulic flow and hydraulically adjustable track width.

All machines are now compliant with level V emissions. n Quatrak 27hp 4 wheel machine the only heavy duty option for a wheeled remote tool carrier, with a choice of implements. n Evotrak 27hp if steep and low ground impact is important, then the lightweight, low cost, tracked Evotrak is the solution – the machine of choice for extreme angles. n Deltrak 2.5 – a tried and tested stable high performing remote tool carrier, Kubota high torque engine, with a variety of options from mowing seeding and cultivation. n Deltrak 50 V3 is the latest edition to the Irus line up. Doosan common rail engine, variable track width, automatic track tensioning. 50hp with 80 l/min hydraulic power, Various implements available for this high performing tool carrier. n Deltrak 61 V3 – similar in all respects to the 50 V3 but increased power to 61 hp. n Twin – the only double implement machine on the market, seriously strong and very powerful high torque Doosan common rail engine, 75hp,120 litres/min. Various implements available. The key for high productivity and low ground impact is headland turns are not required just lower the second implement and traverse back for the next cut.

Irus now have a choice of Remote machine to fulfil most categories, a strong UK support team dedicated to ensure timely spares supply, technical assistance and onsite repairs and training.