2 minute read

Automated forward geological prospecting

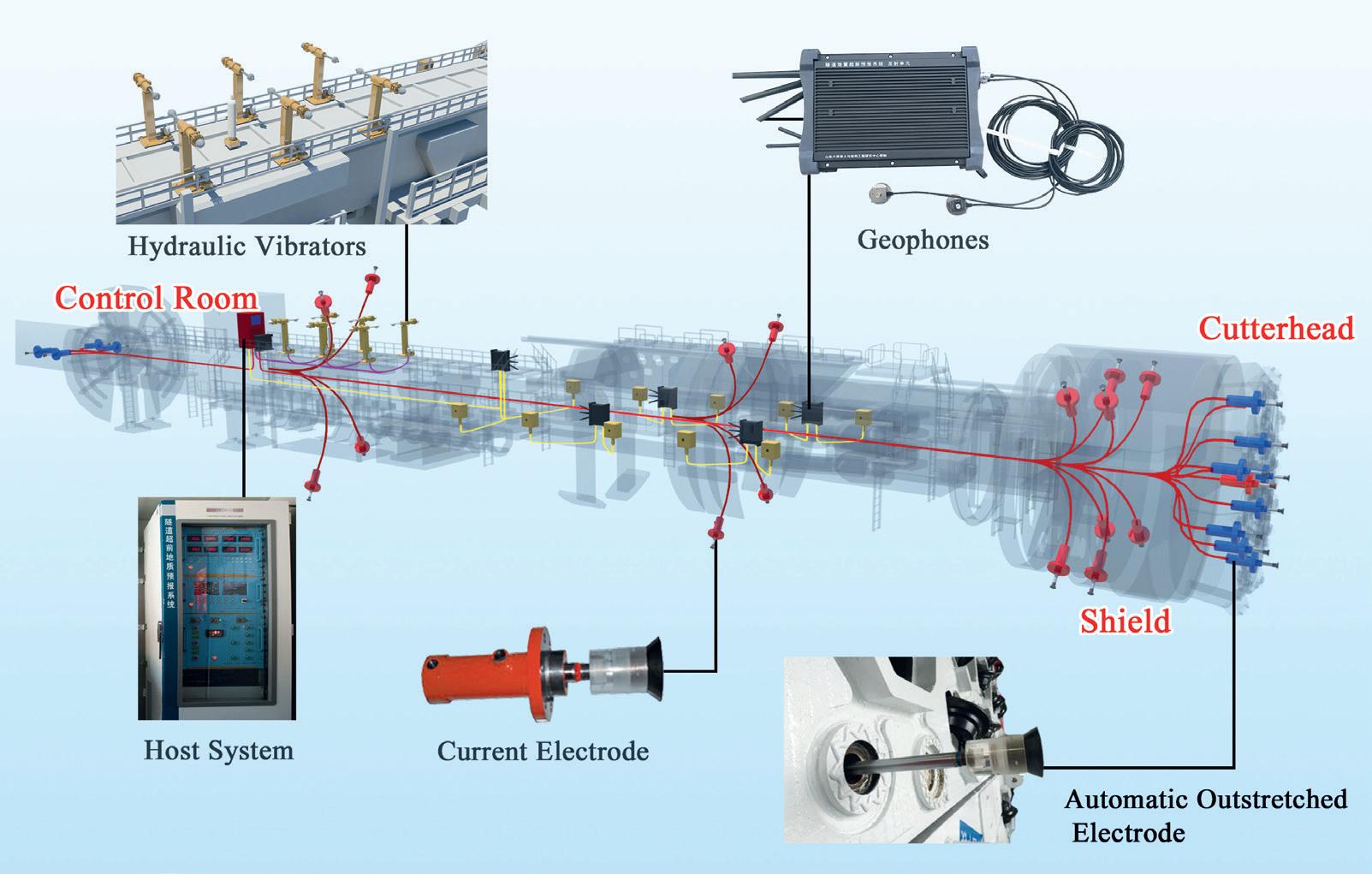

Starting from the premise that hard rock TBMs have poor adaptability to adverse geology, unknown faults, karst caves, groundwater bodies and fractured rock zones, the research team at Shandong University in China has developed an automated geological forward prospecting technique.

Detection of adverse geological conditions ahead of hard rock TBM drives is an important prerequisite for the safe and efficient construction of TBM tunnels. Many TBM drives over the years have encountered geological disasters, resulting in TBM blockage or damaged, heavy economic loss and in some cases personnel casualties. Forward prospecting of adverse conditions ahead of the cutterhead is of crucial importance for project success.

Advertisement

To address this requirement, a technique has been developed to detect geological anomalies ahead of an advancing hard rock TBM tunnel face. There are traditional geological prospecting methods used with drill+blast excavation, but these present great challenges when applied to TBM drives:

• TBMs provide little space availability for prospecting;

• Electromagnetic and vibration interferences are severe and affect the effectiveness of signals; and

• TBM tunnelling is five to 10 times faster than traditional drill+blast, requiring faster detection techniques.

To address these problems, the automated geological forward prospecting technique is developed to be mounted on TBMs and is based on seismic prospecting to detect karst caves, voids, faults and fractured rock zones and time domain tunnel induced polarization for detecting water bodies ahead of TBM excavation faces. Automated data acquisition is recorded via remote control and presented to TBM operators in a graphic visualization mode. The technique and system has been applied over 1,300 times on 21 TBM engineering projects without missing any major geo-disaster sources.

Actual applications

Of the more than 60km of on-site applications, installation on the fourth section of the Yinsong water supply project in Jilin Province, China, was for a 7km TBM drive through limestone with a high risk of water inrushes. The automated geological forward-prospecting technique was applied 139 times and successfully detected 61 major water-inrush sources.

As an example, the TIP detected a low resistivity area and the seismic method identified a strong reflection. As a result, a large-scale water-bearing structure about 20m ahead of the tunnel face was successfully recognized. The Underground in ActionU construction routine was adjusted in time to deal with the 1,500m3/hr of waterinrush that was revealed by advance of the excavation to ensure safe construction. The TBM operation, as assisted by the technique, was safeguarded and the tunnel project was completed nine months ahead of the anticipated schedule.

On the Gaoligongshan highspeed railway project, the TBM was expected to tunnel through 19 faults and several strong-weathering zones that present high risks of water-inrush and collapse. The automated geological forward-prospecting technique on the TBM was used 98 times and detected 43 sources of potential geo-disaster. On one occasion, two fractured zones ahead of the face were identified.