6 minute read

IS THE SUN FINALLY RISING ON THE COMMERCIAL POTENTIAL OF FUSION ENERGY?

By Nicky Godding, Editor

Nuclear fusion is increasingly being acknowledged as the ultimate clean energy solution. It’s low carbon and safe, and the UK is a global leader in its development – the government even has a strategy for it.

The biggest nuclear fusion device is the sun, but how do we replicate that on earth?

Achieving nuclear fusion is one of the world’s toughest physical challenges, and although it has been done successfully enabling nuclear fusion for a nano second, the challenge is now on to engineer continuous nuclear fusion that can release more energy than goes into creating it, making it commercially viable for the first time.

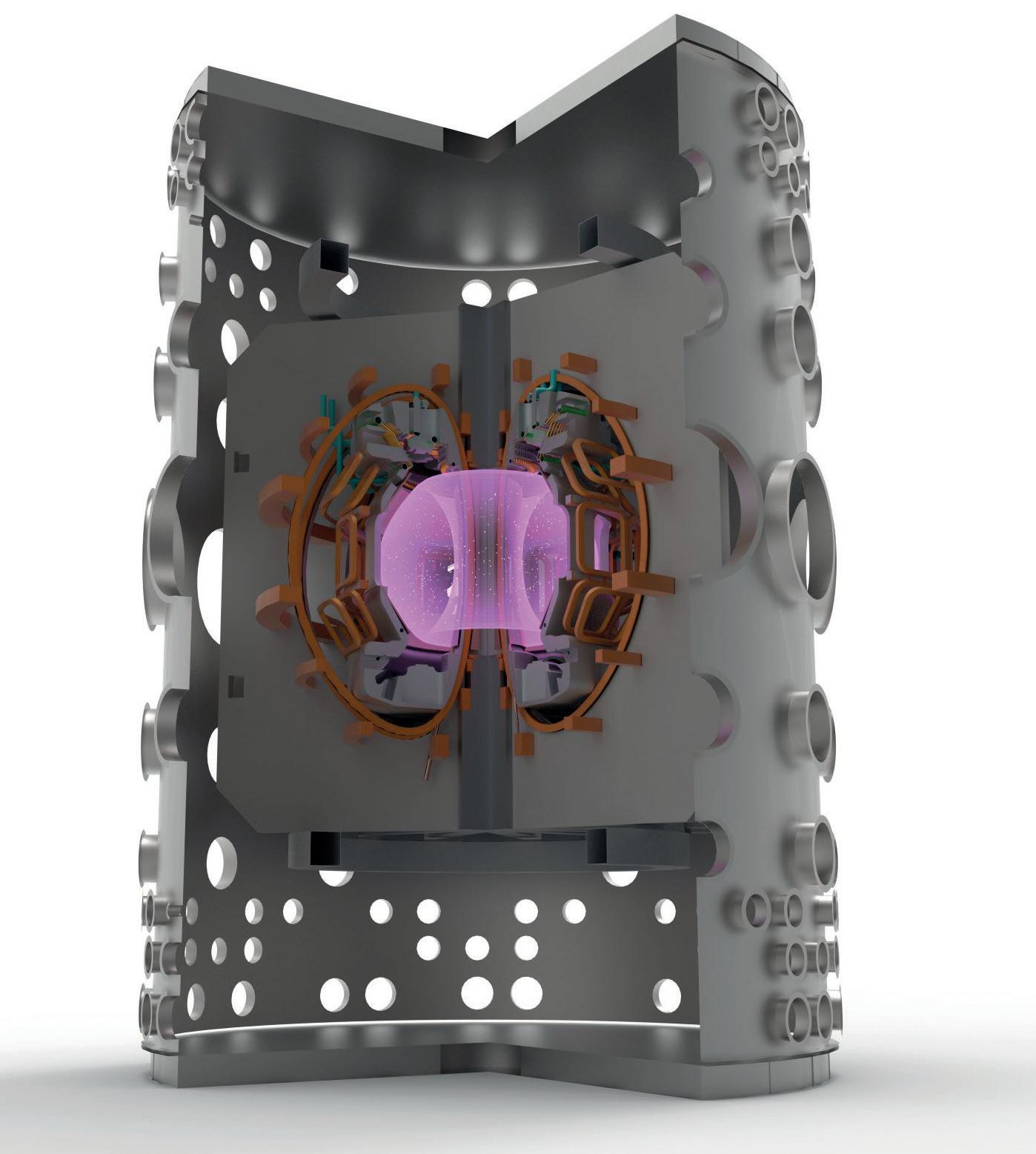

Oxford-based Tokamak Energy is leading the way. It is developing spherical tokamaks alongside high temperature superconducting (HTS) magnets made using rare earth barium copper oxide which the company applies to a metallic substrait tape and uses to design and build robust high field magnets.

A tokamak, for the uninitiated, is a high-tech machine that confines plasma (a charged ball of gas) using magnetic fields in a doughnut shape that scientists call a torus. In the 1980s, one of the founders of Tokamak Energy, Alan Sykes, who was working at Culham Centre for Fusion Energy near Abingdon, discovered that by moving from a doughnut-shaped plasma to a cored apple-shape, the plasma is contained more e ciently.

And so the spherical tokamak was invented. But that was just the start. Very high temperatures and strong magnetic fields are also needed to hold the ball of plasma (which is where the fusion reaction will happen as hydrogen atoms are forced together to fuse and generate energy), hanging in the centre of the tokamak for a length of time. This is called the triple product – a measure of plasma temperature, density and confinement time.

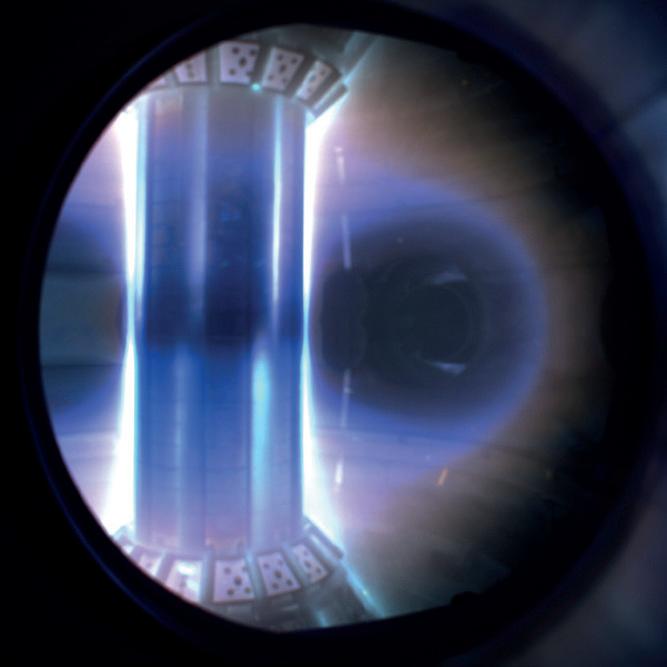

Dr Ross Morgan has been the commercial director at Tokamak Energy for more than six years. He said: “We have demonstrated the highest triple product of any fusion company, and the highest temperature.

“The temperature in the sun’s core is around 15 million degrees Celsius. At Tokamak we have achieved 100 million degrees Celsius which, for the first time, means that plasma temperatures relevant for commercial fusion energy can be obtained in a compact, high-field spherical tokamak. When combined with our world-leading magnet technology, we think our spherical tokamak is the best route to achieving clean, commercial fusion energy.”

The power of collaboration brings fusion experts together

Simple? Well, yes in theory. Absolutely not in practice. And while Tokamak Energy and other fusion innovators across the world know how it can be done, achieving it involves a lot of clever physics and sharing knowledge globally.

“We are running a number of technology programmes to develop and prove out these di erent science challenges from magnets to shielding materials, but we are not doing this on our own,” said Ross. “Fusion is a big opportunity. We recognise where we have strengths and capabilities, and work with the leading research bodies and industrial companies around the world. We also have a strong relationship and collaboration with UK Atomic Energy Authority (UKAEA) and our next demonstration device, ST80, is being built at Culham. It is one of several plants being built there as UKAEA has successfully developed the campus into a globally recognised fusion cluster.”

Alongside Tokamak Energy’s ST80

Tokamak to be built at Culham (which, for the first time, will integrate the spherical tokamak with its HTS magnets to enable a long pulse operation – up to 15 minutes –on the journey to full commercial viability), Canadian company General Fusion is also building a demonstration plant there which will demonstrate its proprietary Magnetised Target Fusion (MTF) technology, paving the way for the company’s subsequent commercial pilot plan.

And Oxford-based First Light Fusion, pioneering yet another way of creating fusion energy, is also building a new facility at Culham to house its Machine 4, which will be used to develop the technology required for inertial confinement fusion energy powerplants.

The UK government is supporting these fusion ambitions, not least financially but also with appropriate regulation. Fusion is very di erent to nuclear fission, which is at the core of the UK’s current fleet of nuclear reactors such as Hinkley Point B and the under-construction Hinkley Point C. With fusion, there is no long-lived radioactive waste but if you lose power with fission there is potentially a problem with runaway chain reaction. If you lose power and containment in fusion, the energy just dissipates. Fission wants to keep going. Fusion wants to stop.

So the government has agreed to regulate fusion like any other industrial process, through the Environment Agency and Health and Safety Executive (HSE).

Ross says: “That sends out a powerful message that the government recognises the benefits of fusion in terms of low risk and low hazard. Having an appropriate and proportionate framework means that you can deploy quicker and at lower cost.”

This also supports another benefit for the generation of fusion energy, Ross adds. “Unlike fission, where our nuclear plants are as far away from urban areas as possible, with fusion you can have a modular tokamak plant close to centres of industry.

“That’s important not just for power generation for the grid, but also using fusion energy to generate heat for some of the harder-to-decarbonise processes. These include steelmaking and aluminium, hydrogen generation and ammonia production – and in other parts of the world, desalination. These are very energy intensive processes that can’t be serviced by renewables because they need continuous heat and power. We see fusion as complementing renewables to move to and sustain net zero.”

Tokamak grows staff count and ambition

Tokamak Energy’s approach to fusion, for which it has filed more than 70 international patents, has seen the company grow from just 25 people a few years ago into 250 members of sta , from around 30 countries spread across two large sites at Milton Park near Abingdon. This is in addition to its expansion at Culham as it brings it two core technologies together: the spherical tokamak and its HTS magnets.

It is also talking to potential investors and suppliers around the world and earlier this year signed an agreement with Japanbased Furukawa Electric Co which will supply the larger quantities of magnetic tape required to build the new ST80 at Culham.

“When our demonstration plans have been proved, we will look to licence our technology out to power plant constructors,” said Ross.

“When I joined Tokamak more than six years ago, it was focused around the research and development. Since then, we’ve developed the engineering capability and commercial and business skills to take the business to the next level.

“We are also looking at where else our magnets can usefully be applied, from scientific instruments to aviation and the space industry.

“The UK is a centre for fusion, and Oxfordshire has been the centre for super conducting magnets ever since the advent of Oxford Instruments and Siemens, so we have been really fortunate to attract some of the world’s leading fusion and magnet engineers to the region.”

Tokamak Energy has raised around $250 million to date. $200 million of that has come from private investors and around $50 million from UK and US government support.

“These are long-term investors who are interested because of the potential of their investment,” said Ross. “More private investment is also coming into the sector, which is now exceeding that from the public sector. This benefits businesses such as ours as we can move faster and become less constrained by government funding cycles.

“What’s great about Tokamak Energy is that we are all working on cutting edge science and engineering and trying to achieve something that’s meaningful which helps to guide us away from fossil fuels. It’s what motivates us all.”

THE BUSINESS MAGAZINE

IS NOW THE LEADING VOICE OF REGIONAL BUSINESS COMMUNITIES FROM THE WEST MIDLANDS DOWN TO THE SOUTH COAST

Boulevard expands to Amazon Japan

Worcestershire-based marketplace seller Boulevard has expanded into Amazon Japan.

The top 500 seller status company in multiple countries across Amazon, eBay and other worldwide marketplaces has achieved 1,370 per cent growth in the past seven years, averaging a rate of 100 per cent growth year on year.

By joining Amazon Japan, the third largest online marketplace after Amazon.com and eBay.com, Boulevard aims to significantly increase its own market share, while introducing its growing customer base into new international territories.

Launched in nine categories so far on Amazon Japan, including toys, clothing and homeware, Boulevard has already added several major brands to its partner portfolio, including homeware and fashion brand Sass & Belle, and fancy dress giants, Smi y’s.

Jack Steggles, Head of Revenue for Boulevard, said: “Launching on Amazon Japan is our first expansion into the Far East, and an incredibly exciting milestone for Boulevard given Amazon Japan’s considerable market share in providing 11 per cent of Amazon’s global online tra c.

Dominic Portman, Founder and Managing Director of Boulevard, confirmed: “Our expansion to Amazon Japan marks the 10th international marketplace that Boulevard sells on, and our aim is to continue that trajectory of growth with launches into a further six new marketplaces this year.

“As a company, we provide a route to huge audiences within the UK and internationally for our partnered brands and distributors.”