1 minute read

Strategic Recommendations

Product Overview Product of Interest: Undersea Fiber Optic Cable

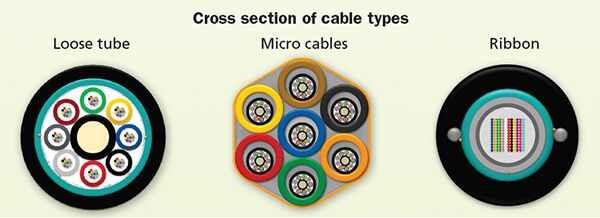

• Loose Tube: The loose-tube cables are mostly used cables which are specifically designed for harsh outdoor environments. They protect the fiber core, cladding, and coating by enclosing everything within semi-rigid protective sleeves or tubes. In loose-tube, cables that hold more than one optical fiber, each individually sleeved core is bundled loosely within an all-encompassing outer jacket.

Advertisement

• Ribbon Tube: The ribbon fiber optic cable is generally a ribbon of optical fibers, which is formed into a flat strip. This is done by manufacturing a series of individual optical fibers and laying them flat and bonding them to each other. Using this technology as many as 24 optical fibers can be put together. The fibers are typically placed side by side forming a flat ribbon. Ribbon cable has been around for so many decades, however, the use case for it is becoming more widely accepted and adopted.

• Micro Loose Tube: The micro loose tube cables were firstly manufactured in Europe as the innovative approach for installing numerous optical networks for the congested duct environments. These miniaturized micro loose tube cables, with increased fiber counts per cross-sectional areas, could be installed with less cost and disruption than a rip-and-replace solution. Micro loose tube cables can act as a bridge option for lower fiber counts (from 12 to 288 fibers) that can scale up in the future with minimal installation cost.

• Others: Others include Tight Buffer Tube, Metal Tube, etc.