3 minute read

The Bioplastics Revolution: Paving the Way for Sustainable Materials

from SPN June 2023

by spnews.com

By Dominy Jones

In recent years, the global focus on environmental sustainability has led to a surge in innovation within the materials industry. One groundbreaking development gaining significant attention is the bioplastics revolution.

Advertisement

Bioplastics, derived from renewable sources, present a viable alternative to traditional petroleum-based plastics, offering numerous environmental advantages. This article explores the growing prominence of bioplastics and their potential to revolutionize the way we produce and consume materials.

A Sustainable Solution

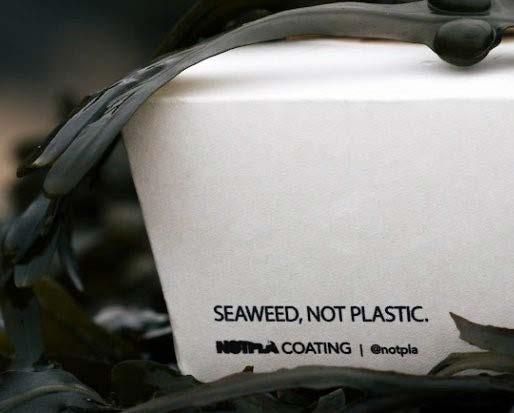

Bioplastics are composed of organic materials, such as starch, cellulose, or polylactic acid (PLA), derived from plants like corn, sugarcane, or even algae. Unlike their conventional counterparts, these materials are biodegradable and have a significantly reduced carbon footprint. By utilizing renewable resources, bioplastics mitigate reliance on fossil fuels and contribute to mitigating climate change. A great example of this is Notpla’s takeaway food boxes that are lined with a unique solution, Notpla Coating, the London-based firm’s most industrially advanced product.

This coating is made from seaweed - one of nature’s most sustainable resources- and plant extracts. Globally abundant and fast-growing, seaweed doesn’t require fresh water or fertiliser and does not compete for arable land, unlike many land-based natural crops. Seaweed also reduces ocean acidification and effectively absorbs carbon, making it one of our greatest weapons against climate change in the foodservice industry.

Reducing Plastic Pollution

One of the most pressing environmental issues today is plastic pollution. Conventional plastics take centuries to decompose, leading to an accumulation of waste in landfills and oceans. Bioplastics offer a potential solution to this problem. They can be designed to degrade naturally over time, reducing the long-term impact on ecosystems. Additionally, some bioplastics are even compostable, meaning they break down into organic matter that can enrich the soil.

For example Coffee capsules made of Solinatra are 100% natural, plant-based, biodegradable, compostable and contain zero fossil-derived ingredients nor leave behind any microplastics. The innovative capsules have high oxygen barrier and water vapour barrier properties, meaning the coffee stays fresh for a perfect brewing experience every time. Solinatra CEO, Robert de Jong: “We’ve developed our natural and plant-based materials to be the solution to fossil based, polluting plastics. The certification is confirmation that Solinatra is the truly sustainable choice.”

Applications and Advancements

The bioplastics revolution has sparked numerous advancements in materials engineering and manufacturing processes. Bioplastics can be used to produce a wide range of products, including packaging materials, disposable cutlery, textiles, and even medical implants. Researchers are continuously exploring new applications and refining bioplastic formulations to enhance their properties and durability, making them suitable for a broader array of uses.

Economic Benefits

Beyond environmental advantages, the bioplastics industry presents significant economic opportunities. As the demand for sustainable alternatives grows, so does the market for bioplastics. This creates a new avenue for job creation and economic growth. Countries and companies that invest in bioplastics research and manufacturing can position themselves as leaders in the global transition towards a more sustainable future. TotalEnergies Corbion Luminy® PLA bioplastics are derived from sugarcane, an annually renewable resource, and are among the few types of bioplastics that are both biobased and biodegradable.

As outlined in the “Planting the Future with PLA,” whitepaper, creating a kilogram of PLA requires 1.75m² of sugarcane farmland which captures 1.8kg of CO2 from the atmosphere as it grows. TotalEnergies Corbion’s entire production capacity requires just 0.08% of arable land in Thailand, where the company produces PLA locally. Simply put, the efficiency of land use combined with the benefits of carbon capture make PLA bioplastics a great option for reducing our global reliance on fossil-based plastics.

Challenges and Future Outlook

While the bioplastics revolution is gaining momentum, challenges remain. Scaling up production to meet the demands of a growing market can be a complex task. Additionally, there are concerns regarding the availability of land and water resources for growing the necessary crops. Research and development efforts are underway to address these challenges and improve the overall efficiency and sustainability of bioplastic production.

Looking ahead, the bioplastics revolution holds tremendous potential. As technology advances and economies of scale are realized, bioplastics are expected to become more costcompetitive with traditional plastics. With continued innovation and investment, we can envision a future where bioplastics become the norm, replacing fossil fuel-based plastics and significantly reducing our environmental footprint.

Conclusion

The bioplastics revolution represents a significant step forward in the quest for sustainable materials. By harnessing the power of nature, these innovative materials offer a promising solution to plastic pollution and the associated environmental challenges. As we embrace bioplastics and support further research and development, we move closer to a world where materials are not only functional but also kinder to our planet. The future is bright for the bioplastics industry, and its revolution is set to shape a greener, more sustainable world for generations to come.

Biesterfeld

“ Biesterfeld makes its technical expertise available to its customers, supporting them on the path to sustainable product development ”