1 minute read

Bandall set to exhibit innovative banding solutions with sustainable impact at Interpack

from SPN April 2023

by spnews.com

If you are looking to make your primary or secondary packaging considerably more sustainable, then a visit to Bandall’s stand is a must.

Advertisement

An 80-90%+ reduction in packaging material is not unusual. Whatever it is you wish to band, it always results in savings on material, energy, and working time. Most of the applications are at the cutting edge of bundling, labelling, and sealing in both the food and non-food sector.

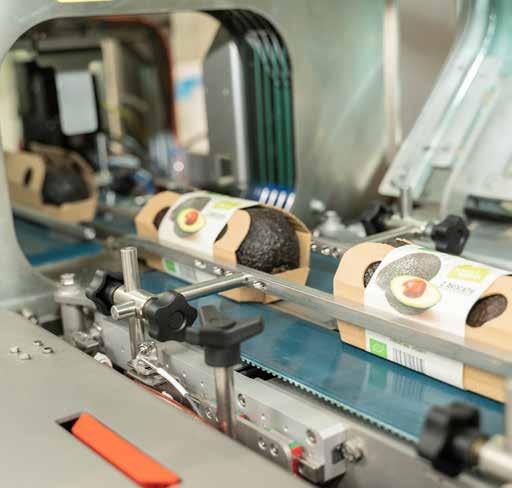

A lot of attention is devoted to banding using paper, combined with a variety of success stories in which the banding concept has boosted sales. Also think of the Successful Branding by Banding™ concept (in collaboration with Specialist Printer Max. Aarts). A lot of attention also goes to the flexibility and efficiency of the various Bandall technologies. The latest fully automatic machines are extremely modular and can be used flexibly when it comes to bundling and/or labelling food and non-food products. In recent years, the machines have been innovated, and various user-friendly features have been added, making them easy to adapt to a wide range of products.

Examples include the fast bundling of small bags of detergent, sweets, sponges, small boxes or even bottles containing products like fabric conditioner or all-purpose cleaner. Savings of up to 90% are not uncommon. Good for Retail and Shelf Ready packaging, as well as for value packs.

The optional interchangeable arch makes it possible to run multiple banding widths on a single machine. With a diverse range of printing technologies, variable data (such as bestbefore dates, lot numbers or barcodes) can be printed during the banding process. Both options make banding even more flexible and efficient. Making variable information easy to change helps prevent unnecessary waste in terms of labelling material.

At the Interpack, Bandall will be showcasing both Stand Alone banding machines as well as part of its renewed line of fully automatic banding solutions. The innovations are attributed to numerous details in terms of speed, ease of use, ease of maintenance, reliability, and flexibility. An example is the Bandall V-TXL, which makes extremely high-speed banding of products possible, partly thanks to its advanced band control and servo technologies. We will also be displaying an innovative stacking and bundling machine for small boxes. Ideal for industries such as pharmaceuticals, where at least 80% of material reductions are achieved.

Visit Bandall at Stand C42 in Hall 5. If you are interested, but do not have the opportunity to visit us during the event, please feel free to schedule a virtual meeting. We will welcome you in our beautifully decorated virtual studio where all banding possibilities will be shown.