26 minute read

Interview

Noonan Shauna

SPEI President 2020 By Abdallah Sharaf

Advertisement

Shauna Noonan is the chief of artificial lift engineering for Occidental Petroleum Corporation, based in Houston, where she directs the company’s efforts in artificial lift system performance globally. Prior to joining Oxy in late 2015, she worked worldwide on artificial lift projects and technology development at ConocoPhillips and Chevron for over 22 years. She has authored or co-authored more than 25 technical publications on the subject of artificial lift and is a frequent speaker at industry events. She has been an avid SPE volunteer in many roles since first serving as a student section officer. She served on the SPE International Board of Directors as the Technical Director for Production and Operations from 2012-2015. She has driven the development of industry standards and recommended practices for artificial lift systems while serving as chair for ISO and API committees, and has received industry awards for her contributions to the discipline. Noonan holds a BS degree in petroleum engineering from the University of Alberta. She is the proud mother of two daughters.

1. We are eager to know more about yourself, your studies and your professional career.

4 I am originally from Canada and got my Bachelor of Science degree in Petroleum Engineering (Co-op) at the University of Alberta. The “Co-op” refers to a 5-year degree program that incorporates five 4-month industry internships, so upon graduating, one has an engineering degree AND twenty months of work experience. For my internships, I worked for Mobil, Hess, Canadian Hunter, and then twice for Chevron. After graduation, I began working for Chevron out in the field on the rigs. Like many of our SPE members, I was a workover engineer, rig supervisor, field engineer, production engineer, and an artificial lift specialist in the corporate engineering group that had me travelling to Chevron’s assets all over the world. In 2004, after 12 years with Chevron, I was looking to strengthen my artificial lift knowledge so I moved to ConocoPhillips’s corporate engineering group, where I started working as an artificial lift specialist. Several years later, I was managing the Completion Technology team, made up of completion, geomechanics, and reservoir engineers focused on developing technology for unconventional shale reservoirs and the Canadian oil sands. In 2015, I was appointed to the position of the Director of Artificial Lift Engineering for the Occidental Petroleum’s global operations after a company executive heard my speech at an industry event. I’ve worked in field asset teams, technology development, corporate engineering, and executive management. I have worked on miscible floods, extra-heavy oil, steam floods and SAGD, coalbed methane, and unconventional shales. I have worked for multi-national and independent oil and gas companies on projects all over the world. As a result, I can relate to so many parts of our business.

2. How did you draw up your success story with SPE until you reached this great position as 2020 SPE International President?

I started my SPE involvement as the Vice President of my student chapter. Since that time I have served on all types of SPE committees all over the world, authored over 25 publications, taught an SPE course and webinar, given many panel and keynote presentations, and was also associate editor for the SPE Production and Operations Journal. From 2013 to 2015, I served on the SPE Board of Directors as the Technical Director for Production and Operations and chaired the Training, Programs and Meetings Board Committee. I have been blessed to be the recipient of several SPE awards: SPE Gulf Coast Section Regional Production and Operations Award (2012), SPE Peer Apart (2011) for technical editors of more than 100 papers, SPE Outstanding Associate Editor: Production and Operations Journal (2010), and outstanding SPE Outstanding Technical Editor (2007). I have experienced the global business and culture of both our industry and SPE, which brings a very positive perspective and strength to my role as SPE President.

3. Every successful manager has many challenges in life, so what are the challenges you faced? How did you overcome them?

Being able to communicate effectively and work well with others in a team environment is crucial in our industry. You could be the most brilliant person in the room technically, but if you are not able to express and explain your ideas, or if you are a poor team player, the doors of opportunity will be closed to you. Working with engineers to improve their soft skills can be difficult, as many won’t admit they have poor soft skills, and the steps to improve them may put them outside their comfort zone. I recommend your SPE Student Chapter for having a Soft Skills Club and helping your members develop those needed attributes prior to graduation. The earlier one develops great soft skills, the better it is for one’s career progression.

4. How can you see the Middle East support for SPE activities in 2020 and before, especially in Egypt?

In March 2019, the SPEI Board of Directors meeting will be held in Cairo, which is a huge opportunity for the Egyptian section and student chapters. During this time, the Board and local SPE members will be discussing how the Society can best support our Egyptian members, and what events can be planned for 2019 and 2020.

5. What do you expect for the future of the Oil & Gas Industry generally, and Artificial Lift as your career especially?

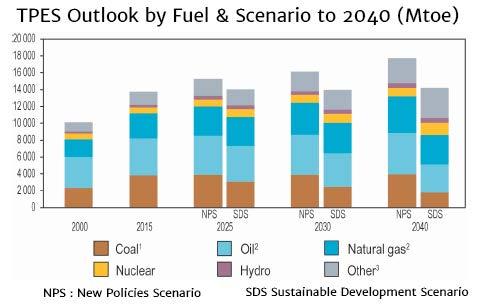

In the 2018 IEA report titled “Key World Energy Statistics,” the outlook for oil and gas consumption into 2040 (see Figure 1) provides great insight into the future of our industry and the continuing need for oil and gas. In terms of artificial lift, most companies have over 50% of their producing wells on some form of artificial lift, which is great. The latest advancements have focused on increasing the electrical efficiency of artificial lift systems and transitioning to electricity generated by renewable sources, such as using solar-powered rod pumping systems as shown in Figure 2.

ECHO - Feb 2019 Figure 1—2018 IEA Projections of Future Energy Demand Figure 2—Solar power array provides electricity to beam pump (photo courtesy of Santos).

6. What are the events or projects of the Oil & Gas Industry in the Middle East that caught your attention last period, and do you expect great progress in the Middle East’s petroleum industry?

There are many great projects in the region that I have been following, but the one that has garnered my attention the most is the Al Hosn Gas Project in the UAE. it is one of the largest natural gas developments in the Middle East that set the bar in terms of construction excellence and production performance.

7. Could you tell us about your upcoming plans for SPE International generally, and SPE YP or student chapters worldwide specifically?

Two of my initiatives that SPE YPs and student members can relate to most is increasing corporate support and improving the methods in which SPE delivers its technical content. A huge part of my technical and soft skills development was due to the opportunities I pursued within SPE; however, much of this required the support of my employer. During my three years on the SPEI Board as President-Elect, President, and Past President, I plan to educate and engage more companies to support and encourage their employees to participate in SPE programs. I honestly believe that a huge growth opportunity for SPE lies in the geographical areas where there is already an SPE presence, but not full engagement yet by the industry. The engagement of our volunteers and having that corporate support for them is essential for the future of the Society. In discussions with many SPE student members and even the YPs, I have learned that most do not read the JPT, or access technical papers in OnePetro.org. The feedback I get is that it takes too much time and that knowledge transfer needs to be delivered in methods that can be accessed and consumed in less than 30 minutes. I am currently working with SPE staff on solutions and plan to utilize Podcasts more often for content delivery, such as using them to complement my President’s Monthly Column.

8. As a student chapter, we have achieved many awards as outstanding chapter and golden standard awards more than once. What’s your advice for us to continue our march and conserve our success?

Congratulations on all the awards. Your members should be proud of those accomplishments. Forty-five percent of the award criteria is what your chapter has accomplished in Industry Engagement (30%) and Community Involvement (15%). The first two criteria require reaching out and interacting with people outside of your academic institution. Contact other SPE student chapters to see what they have accomplished and share your ideas as well. Reach out to SPE professional members for their feedback. Communication and collaboration leads to innovation.

9. Kindly, give some advice to students and fresh graduates who are about to join the actual industry life.

The very first thing I tell students is to get out to the field, regardless of which petroleum engineering function you want to pursue. You get to really understand how operations work, and you get to learn the “lingo” to better communicate with your field operations staff. You need to “see it and live it” in order to be a better and more effective petroleum engineer. Find multiple mentors, learn from them and create your own career path. There is no pre-determined career path for you to follow and it is not up to your company to plot your career. Get more than one “success story” and piece together your own plan. Having good mentors can also “open up doors” internally and externally. In addition to getting advice with career planning, there is much you can learn from more experienced engineers and geoscientists, so be like a sponge and soak up everything you can. Don’t be afraid to ask questions. Finally, SPE is there for you. It has endless resources available to help you in all the various roles you will experience. Utilize OnePetro.org, Petrowiki. org, SPE webinars, the Competency Assessment tool and stay current on industry issues through JPT and JPT online. Go to section events and find your way onto a committee where you can expand your industry network.

Interview with Mr. Sameh Sabry

By Mahmoud Morsy - Ahmed Mukhtar - Essam Mohamed

1. Firstly, Could you tell us more about your professional career?

In total, I have 18 years of experience in upstream and downstream oil and gas industry. During these years I have been working for a number of multinational companies, starting with ExxonMobil, followed by Chevron and then currently working for DEA (DEA Deutsche Erdoel AG) for the last 10 years. I have an international exposure which is focused on Europe and North Africa. I have been based in DEA HQ (Hamburg, Germany) two times during my career where I worked there for 4 years in total in two different roles. At the beginning of my career I focused on commercial, business analysis as well as business development roles. I have assumed the roles of Commercial Manager for DEA in Europe during 2012-2014 and the role of Commercial and Business development Manager for DEA in Egypt during 2014-2016. Afterwards, I moved to general management roles, where I assumed the role of Deputy General Manager for DEA in Egypt, followed by being assigned as General Manager for DEA business in Algeria during 2017-2018. During my assignment in Algeria. My latest move was coming back to Egypt starting August 2018, as General Manager for DEA Egypt and board member for our JVs with EGPC and EGAS (SUCO and Disouco JVs).

2. How did you draw up your success story to be the general manager of DEA in Egypt?

ECHO - Feb 2019 If I try to summarize the main factors of any career success, I would say that continuous learning and self-development are the key factors. As pointed out, my career was focused on commercial and business related roles. However, exposing myself to new experiences and continuously seeking new tasks and challenges, allowed me to learn fast about all other functions in our industry and increase my experience significantly in very short time. I was always keen to expand my knowledge and enrich my role beyond job boundaries. In particular, by leading cross-functional teams in challenging tasks from all disciplines. This was evident, when I have managed to lead my teams to formulate and agree with partners on development plans and commercial deals, which allowed to unlock the developments of significant resources in Egypt (e.g. West Nile Delta project with our partner BP, Disouq gas asset as well an ambitious investment program in our assets in Gulf of Suez). One of the key factors of success was maintaining good performance, as well as in a consistent mode. Ups and downs are natural, but maintaining a reliable level of performance is key for career success. This was evident, when I was assigned to international roles, for example being the Commercial Manager of DEA in Europe between 2012- 2014, many suspected that my level of performance will decline due to stepping out of my comfort zone and being exposed to different business cultures and environments. However, I have managed to maintain my level of good performance and supported DEA senior management and teams to develop number of key projects in UK as well as in Norway. My ambitious and readiness to get out of the comfort zone paved the way for me to advance my career to general management roles. Starting by being assigned as General Manager for DEA in Algeria during 2017-2018. In Algeria, I was proud to achieve (with partners) the completion of the development activities and first gas from our first development project in Algeria (Reggane Nord) as well as establishing an excellent relationship with the Algerian authorities which was reflected in signing of a Memo of understanding with the State Company Sonatrach, opening the door for future cooperation and joint projects in the near future. This career record allowed me to compete and then be selected in an open internal application process for the General Manager position in DEA Egypt.

3. We are eager to know your majors and degrees which you had achieved and your plans when you were a student.

Well, I acquired my Engineering bachelor degree (Civil section) from Ain Shams University in Cairo in 2001 with honours and was ranked as one of top 15 students of this class. In 2006, I acquired my Master of Business Administration, MBA from Arab Academy for Science and Technology & Maritime Transport- Cairo. As a student, I was always keen to monitor closely the potential employers in the Egyptian job market, to better assess what the job market is really needing and accordingly focus my studies on areas of job market interest. I was also keen not only to develop my knowledge but also my set of skills. Remember business is human and not just science, so communications, presentation and analytical skills are also key.

4. What do you expect for the future of the industry?

The future of the oil and gas industry is currently under wide debate. There are some views that predict a decline in the oil and gas market in the mid/ long-term future. Those who believe in this are arguing that the demand for conventional hydrocarbons will quickly decline and will be taken over by the switch to renewables for power generation and the rise in electric vehicles, hybrids and the likes. However, I personally believe that the oil and gas industry has still many years of good business. Most of the reputable institutes predict a continuity in increase in oil and gas demand before seeing some gradual decline by the 2040s. I strongly believe that the oil and gas companies will be able to adapt itself to market developments through re-focusing its energy mix, developing new technologies to reduce cost and improve environmental print. So, I can comfortably argue that altogether the future of oil and gas industry is definitely good for the next decades.

5. The industry is diverse in different ways, how do you see diversity in the oil and gas industry, especially, SPE has established a new committee called Women in Energy?

I am a strong advocate of diversity in oil and gas industry in Egypt. Having said this, diversity in my view extends to not only to its key part of gender diversity, but also extends to diversity in races, colours, nationalities, ethnicities, religions as well as personal believes and identities. On my

SPE Suez team with Mr. Sameh Sabry

very first day in DEA Egypt, as the new general manager, I have gladly signed DEA’s Diversity Mission Statement and invited my fellow colleagues in DEA Egypt to sign it as well. In DEA, we are proud to have a female CEO, who’s inspiring the whole organization on the necessity and benefits of diversity. I am really glad that SPE has established a new committee for Women in Energy and I think that we need to encourage a higher involvement and equal opportunities of females in the Egyptian oil and gas sector.

6. What is your opinion about ECHO magazine?

I was personally positively surprised with high quality and level of professionalism in editing and publishing ECHO magazine. I enjoy reading it, in particular the interviews with key players in the oil and gas industry in Egypt as well as the Case Study and Advanced Technologies sections. Keep it up!

7. As a student chapter, we have achieved many awards like gold standard and outstanding awards, what do you advise us to do to conserve these great awards?

My advice would be to continuously develop yourselves, stay up-to-date in tracking the industry developments and in expanding your network with key players in the industry.

8. What are your plans to support student activities in Egypt?

DEA Egypt is offering every summer internship opportunities for Egyptian students. Even though those opportunities are not big in number, however we make sure that it is a beneficial experience for everyone who joins us. Personally, I plan to work on strengthening the relationship and interactions between the business sector and students through supporting the activities, attending and addressing keynotes to student events and conferences.

9. Kindly, leave a message for senior students and fresh graduates who are about to join the industry at this time

Be ambitious, never rest for less! Persistence and willingness to continue learning and developing yourselves is key for any career success. Believe in yourselves and be positive, don’t get easily demotivated or frustrated when you face a challenge or when you have a failure. Keep trying and never give up!

Interview with Mr. Karim Badawi

1. Firstly, we are eager to know more about your professional career and how you drew up your success story to be the Managing Director- Egypt and East Mediterranean of Schlumberger?

I started my career almost 22 years ago in Indonesia as a wireline field engineer, then moved to Aberdeen working as a field engineer for 1 year. Then I came back to Egypt as the training center manager for wireline product line. I moved from Egypt to Paris as the operations manager of Schlumberger wireline worldwide for 3 years then, returned to Egypt as a wireline operations manager for 2 years for Egypt, East Mediterranean and, East Africa. After this, I moved to Houston US as a process business system manager for operations, which was actually how to use business system to bring efficiency in the service delivery process to all product lines. Then I moved to Russia, Moscow and, I held many different positions. I was IT manager and after one year, I became the vice president for share services: facilities, IT, HR and, finance. Then I was the vice president for testing services. After this, I became the reservoir group manager for Russia and Central Asia. Finally, I became back to my country as managing director- Egypt and East Mediterranean region. I am always motivated to work in Schlumberger and, eager to learn new things and, contribute to its achievements. To succeed well in any role it is never about you, it is about your successful and motivated team.

2. What are the innovative services which were applied recently in Egypt by SLB?

new product lines called OneSurface, which is applied in surface facilities. And we are very proud that we are involved in ZOHR field from the discovery to first gas with different product lines like: wireline, simulation modeling and, surface facilities. Also with our new technologies and integrated services approach we managed to partner with BP to deliver Atoll project 8 month ahead of schedule. We are very proud of our new operational base Egypt Center of Efficiency (ECE). ECE is a great milestone in Schlumberger history.

ECE is a great milestone in Schlumberger history. The learning center inside ECE is considered the first one for Schlumberger in Africa. This new operational base will enable Schlumberger to optimize the performance and increase the efficiency. The following photo is recently captured from Egypt Center of Efficiency in the 6th of October industrial area.

3. What are the efforts behind the scenes of SLB worldwide to deliver a high service quality to the clients?

Schlumberger is the leader of service quality, HSE and new technologies. It always invests in reviewing process to improve the quality and level of the service. In last 3 years, we conducted internal transformational program, which actually helped us to analyze the different processes for the service delivery like: optimum preparation of the equipment.

4. What is your opinion about ECHO magazine?

ECHO is a very good magazine for many reasons. It is made by students, which is very important in your success in the future because you interact with different people and, you know how to edit, how to print, and how to commercialize for it. All these things are keys for your success soon. You share news about different companies, technical articles and, interviews with different profiles, which is an indication of your bright future. I wish you continue this great work and keep it up.

5. As a student chapter, we have achieved many awards like gold standard and outstanding awards, what do you advise us to do to conserve these great awards?

Always think and act that you are not alone. Student activities are very great in integrity and team work. The industry is built on having team work, knowledge and, best practices. You did a great thing so keep your engagement with the industry and try to select good topics for your projects and events and, I think you actually do that. The future is yours, so keep challenging.

6. What are your plans to support student activities in Egypt?

I have many ideas to support all students. One of them is already implemented, which is giving the practical exposure to the students. They know about our different product lines and technologies through filed trip to our bases. Also to make sure our latest software programs are installed in universities labs. We also sponsor selected graduation projects of students at different universities.

7. As one of Egypt oil and gas leaders, we would like to discuss your expectations for the future of the industry in Egypt and the region.

The future of the industry in Egypt is very promising. Egypt now has huge discoveries and projects like: ZOHR field, West Nile Delta and Red sea. I think you will have a fantastic future.

8. Kindly, leave a message for senior students and fresh graduates who are about to join the industry at this time.

My message is to be very positive, do your best and always know that your success depends on your team. Always learn and improve your skills. Take every opportunity to add to your career. Reservoir-Integrated Production System

The smarter way from oil flow to cash flow

Introducing the reservoir-responsive Schlumberger integrated production system equipped with leading process technologies, connecting subsurface and surface expertise from design through operations.

Multidiscipline remote monitoring

The fully integrated production system globally connects the subsurface with the surface. Changes in production are proactively matched and managed, with the constantly updated reservoir model serving as the vital narrative guiding maximum recovery and optimization for any targeted production rate, effluent condition, or export quality requirement.

Digitally connected for optimization

Seamlessly connected, digitally enabled, and software controlled, the production system integrates data analytics, process modeling, and automation of best practices to ensure flow assurance and optimal production.

Our integrated production system provides operators with a global solution that fully connects the subsurface and surface and creates value at every stage in the production life of a field.

Obtain first oil faster, achieve early cash flow, stage investment decisions, reduce risk, and maximize reservoir recovery.

Interview with Mr. Robert Ziegler

By Mahmoud Morsy

Firstly, Could you tell us more about your professional career? How did you manage to be the Global SME Managed Pressure Drilling at Weatherford & Global Deep-water Advisor?

Well I studied petroleum engineering at Montan University in Leoben, Austria, Europe. I was lucky with my professor that time because he was one of the well-known engineers in fracturing. I learned a lot from him. Then I was required to take Shell Distant learning Program to be a certified drilling engineer and supervisor. During my time with shell (1991-1996), I worked as a drilling engineer in the Middle East and West Africa. Then I moved to work in Oman as a completion and artificial lift Operations Engineers. The Oil was very heavy there and most of them were using PCP in a slow rate. Then. I worked for Chevron as a Deep-Water Drilling representative in West Africa. After that, I worked as an exploration manager at Public Investment Fund, then I returned to Shell as a regional-wells technology operation manager in Asia pacific region. In August 2009, I moved to work as a head of Deep-Water drilling in Petronas. Also I worked in many places after that like Cairn India ltd and RZI Deep Water Drilling leaders where my job was a strategic consultant for cutting edge projects, worldwide. Since Nov 2015, I have moved to work in Weatherford, Huston, Texas area as a Global Director of Well Control Technology. And now, I am the Global SME (Subject Matter Expert) for managed pressure drilling and the global Deep-Water advisor.

2. We are eager to know your plans when you were a student.

I studied at Montan University and chose Petroleum Engineering as I want to work internationally and travel around the world. I came from an engineering family, so I chose to become an engineer too. Specifically, I chose petroleum engineering because it is one of the best professions in Europe and all over the world. At the time, I managed found the first student chapter in Austria which is SPE student chapter. I did a great job with my chapter. Every week there was a company coming to my university to discuss a specific topic, I dealt with many big characters and sponsors. We started recruitment at this time to bring the highly-skilled students. I got my master’s degree in Reservoir management from the same University.

3. We need to know more about your volunteering experience.

Volunteering Work is one of the most important things in the life. I have volunteered in many places and the start was with SPE student chapter. With SPE international, I have participated in many events and conferences. I was the program chairman of the Sarawak section. This section was able to double membership during my time. Then, I became a program committee member in SPE/IADC MPD/UBD Conference and the same for the Arctic Technology Conference. I am responsible for setting up the drilling sessions since the beginning of this conference. In 2014, I was the chairman of the program committee of Offshore Technology Conference (OTC) Asia. This was the first time OTC took place in Asia Pacific. We achieved more than 25000 delegates. Also, I am a member of the MPD/UBD committee in the International Association of Drilling Contractors (IADC).

4. What is your opinion about ECHO magazine and how to keep developing?

You really did a great job with your magazine. It’s a very nice and professional one. Every year try to keep developing it to copy with others around the world. Anyway, your magazine is a big work.

Very nice to converse these great awards, you should be a reference for other student chapters, and I think with this performance that you are very professional. You should keep developing in both technical and non-technical skills. Egypt is a big country in our industry, and I think that many companies will help you achieve your goals by providing you with presentations and courses.

6. What are your plans to support student activities in all over the world?

Well, as you know some service companies now are in a bad situation. Thanks to god, Weatherford isn’t one of them. We support all of these activities in technical and non-technical aspects, and you can contact our local company in Egypt to get more support. Also, you can apply for internships in Weatherford.

7. What do you expect for the future of the industry?

Very bright future, we still have 65% to 70% of the original oil in place so we will have more and more decades of oil and gas industry. We have excellent researches in different topics like: advanced drilling techniques and EOR. I believe that all these things will lead us to reach our goal so the way is too long for this industry.

8. Kindly, leave a message for senior stu¬dents and fresh graduates who are about to join the industry at this time.

My message is to see how many graduates like you in many places around the world so why should I hire you? You should stand out of the crowd and do different things. This industry is very competitive so you should cope with its changes. If you like what you study, then you will like what you do. Try to improve your skills and make the best use of them to get a job.

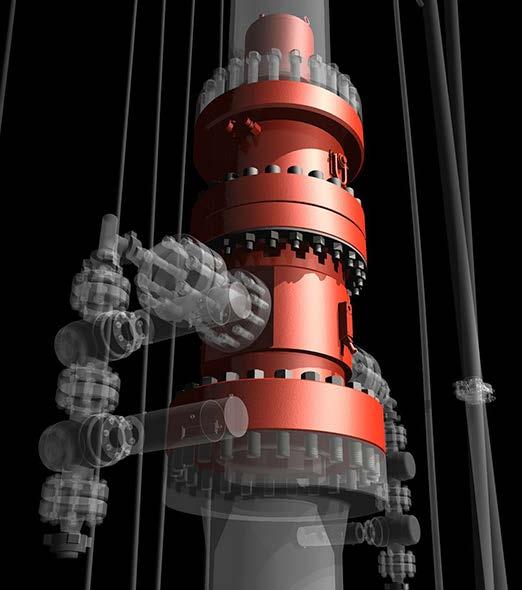

MANAGED PRESSURE DRILLING

Mitigate drilling hazards with precise pressure control

Managed pressure drilling (MPD) provides an active approach to well control. Unlike passive control methods, MPD operations use a closed-loop system that helps to determine the downhole pressure limits and manage the annular pressure profile accordingly. As a result, you can enhance primary well control, verify downhole barriers in real time, and even automatically react to influxes and losses.