19 minute read

Supplier news Updates from SIBA’s Supplier Associate Members

S USTAINABILIT Y IN BREWING

Muntons’ sustainability programme awarded platinum medal

Muntons, the Stowmarket-based malt and malted ingredient manufacturer, has been awarded a platinum medal in sustainability performance by EcoVadis.

This rating puts the maltster in the top 1% of global companies assessed and further highlights it as a leader in sustainability.

EcoVadis is the world's largest independent corporate social responsibility (CSR) rating agency and assesses over 85,000 businesses in 160 countries and 200 industries. It reviews a company’s performance in four key pillars: environment, labour and human rights, ethics, and sustainable procurement. Across the board, Muntons scored 75 out of 100 in the audit, well ahead of the global average of 47. Muntons added the accolade to its everexpanding list of recent achievements, including the Environmental Leadership Award at the 2021 Food and Drink Federation's awards and the Baking Industry Awards' Sustainability Initiative of the Year Award. The 100-year-old business impressed judges with its investment and innovation carried out on its new biomass heating system along with the co-generation of electricity. This, in part, represents Muntons' commitment to sustainability and reduces its environmental footprint in line with a net-zero carbon emissions target. The company is on track to achieve its sciencebased target early and will decarbonise by over 60% based on 2010 emissions. Director of Technical and Sustainability at Muntons, Nigel Davies, said: “It’s an honour to be awarded the EcoVadis Platinum Award. As a business that has set science-based emissions reduction goals as part of our sustainability strategy, the medal recognises our commitments as an industry leader.

“We’re serious about our sustainability initiatives, and the work we do allows us to support our customers and suppliers build greener supply chains and therefore improve the industry’s methods throughout. The platinum award recognises our performance is consistently high in the wider sustainability issues, such as ethics, human rights and procurement."

Muntons sales manager presented with accolade to celebrate the country's highest malt industry exam results

Joe Fifield, a sales manager from Muntons, has been recognised for achieving the country's highest result in his industry exams.

Joe completed the General Certificate of Malting (GCM) last year and achieved a credit grade. The malting industry’s trade association, the Maltsters’ Association of Great Britain (MAGB), named Joe as its highest-scoring exam candidate for 2020. This led to The Macpherson Memorial Trust nominating him for the Association’s prestigious award, the Macpherson Quaich.

Speaking about receiving the Macpherson Quaich, Joe said: “I'm honoured to have received the Macpherson Quaich; it's a tremendous achievement for me and it’s something I’m really proud of.”

During an award ceremony at Muntons' headquarters in Stowmarket, Suffolk, Macpherson Chair of Trustees, Adrian Dyter presented Joe with the Macpherson Quaich.

Murphy & Son launches new PCR service

As the industry recovers from the impact of the pandemic, ensuring the purity of yeast slurries, clean fermenters and serving consistent quality beer has never been more important.

Murphys is therefore proud to announce the launch of its new PCR service that will serve as an important quality control measure across the brewing process, from yeast slurries to packaging.

Despite the pandemic thrusting PCRs into the public eye, PCR (Polymer Chain Reaction) tests have been around since 1985, enabling scientists to amplify a low concentration of DNA to millions of copies in the space of a few hours. This technology has now been harnessed by Murphys for its new service which provides a rapid and reliable PCR based method to detect a range of beer spoilage microorganisms. And as there is no need for culturing on foreign medias, the entire process can be completed in situ. With only a small volume of beer, Murphys can extract DNA and amplify using specifically targeted primers, permitting the species-level identification of beer spoilage yeasts and bacteria and a full PCR run can be completed, analysed, and reported within only a few hours. Through the new service Murphys aims to return all customer samples by the end of the next day.

The new service can also be used on yeast slurry to confirm the absence of any key beer spoilers and also the absence or presence of any diastatic variant, and swabs of other areas of the brewery such as the canning line or containers can also be tested for contaminants.

For more information about the new PCR service email techsupport@murphyandson.co.uk

Now re-named ‘Brewing – The Fundamentals’ Brewing Services ran the first of its new, updated, brewing courses face-to-face for the first time in two years last November. Although restricted to Zoom only teaching for the last two years, this has allowed Brewing Services the time required to re-write much of the course material and update the lecture material.

But Zoom is no substitute for the real thing, and the team was delighted to once again stand up in front of a full course of brewers all wanting to learn more about the underpinning theory behind their day-to-day brewing activities.

The course once again included visits to Fawcett’s Maltings to see the many different types of malt being made and Hambleton Brewery to see their bottling and new canning operations.

The dates for the next course, which will once again be held in York, are 3rd to 6th April and further details can be found on the Brewing Services website.

Read more at www.brewingservices.co.uk

Moody Direct to exhibit at SIBA’s BeerX UK 2022

Leading supplier of liquid processing equipment, Moody Direct Ltd, will be exhibiting a range of process spare parts and components on their stand 184 at this year’s BeerX UK.

As the UK authorised distributors for some of the best known brands in the brewing industry, Moody Direct will have on display components from the likes of Alfa Laval, SPX FLOW, GEA and Keofitt. With such well-developed business partnerships with these original equipment manufacturers, Moody Direct can support breweries no matter what equipment they have on site.

BeerX UK is being held at the Liverpool Exhibition Centre on Wednesday 16th and Thursday 17th March 2022.

Alongside the many industry suppliers that will be at the trade event, there will also be regional beer bars and trade-only beer festival, the SIBA AGM and Members' Conference, the independent beer and business awards presentations, plus a full schedule of seminars, talks and panel debates from the beer industry's leading voices.

Moody Direct has been operating within the brewery sector for over 45 years, allowing the team to build an advanced knowledge of the industry’s process requirements. As a fullservice organisation, it can support breweries with spare parts and components, servicing solutions, integrity testing services, PHE refurbishment, new equipment and complete turnkey projects.

Ken Wild, Moody Direct Director, said: “Whether it’s a single spare part to a process valve or a complete turnkey solution, we’re here to provide much needed, reliable support to breweries of all sizes. We have always valued the importance of meeting with brewers in person at trade events such as BeerX. The prospect of new discussions and connections with a, long overdue, beer in hand, is very exciting.”

For more information visit www.moodydirect.com

OPM Group further invests in digital capability

OPM (Labels and Packaging) Group has announced it has further extended its printing capabilities for brands, packers and retailers in the beverage sector seeking outstanding labels and flexible packaging with investment in a next generation Domino digital press.

The investment sees the company offer a new range of novel added-value print solutions ideal for stand out packs and labels in the drinks industry. The Domino N610i digital press delivers a wide colour gamut with up to seven colours achieving in excess of 92% of the Pantone colour range. With screen-like high quality opaque white for outstanding graphics, the press also incorporates intelligent technology features enabling the production of a range of textures for premium product branding and enhanced shelf appeal.

Chris Ellison, Joint Managing Director at OPM, said: “Beverage brands are experiencing rapid consumer behaviour changes with the pandemic and need their packaging and label partners to be responsive and innovative to help them meet 2022 market trends. By further investing in our digital capabilities, we continue to support our mission to bring our customers customised solutions that meet the quality, flexibility and speed their brands demand, to attract the consumer’s attention when and where it matters most – on the shelf.”

For more information visit www.opmgroup.co.uk

Three costly problems the right brewery pump seal can solve!

Supplier Viewpoint

Whisper Pumps looks at some common pump problems that can be caused by using the wrong sealing…

Whether you're a microbrewery creating craft ales or a big commercial brewery, you are likely to experience some common brewery pump problems caused by having the wrong pump sealing. So, have you been experiencing leaks when transferring hot wort?

In our dealings with brewers, we found that many are unhappy with the life span of their brewery pump sealing. We discovered that the hot wort from the brewing process damages many pumps as the sugar compound contained within alcoholic liquids builds up around the mechanical seals and crystallises. This consequently results in stress corrosion cracking and the seal leaking, which causes the pump to leak and damage the motor.

So, to save you time, money, and lost production, we have highlighted three costly problems that you are likely to experience if you do not have the right pump sealing and provide a simple solution to solve these issues: 1. Leaks and mess – If you are experiencing leaking, you are probably having a problem with the sealing. As the sugars produced by the hot wort are crystallising on the faces of the mechanical shaft seal and forcing the two components apart, the pump will start to leak. This will result in fast and frequent corrosion and messy leaks, which are hazardous and take time to clean up. 2. Damage and downtime - Beer wort pumps are a crucial part of the brewery process; so having to stop using them until the leaks are repaired may result in your production grinding to a halt. This results in the costly loss of productivity, time and potential waste of product.

3. Cost of maintenance, excessive

spare parts and repairs – Although having a pump maintenance plan is key to keeping your pump running smoothly, not having the right sealing can cause unexpected maintenance and repairs.

As the hot wort starts corroding the pump seals, you’ll need to spend time and money to keep replacing them, and this will result in the excessive buying of spare parts. Leaks could also cause

damage to other parts of the pump, which will require costly repairs and ongoing maintenance. After working closely with the brewery industry for many years and testing different pump seals to come up with a solution for this problem, we found a mechanical seal with a material that will withstand the high temperature but does not allow the sugar to adhere to the mating surfaces. After discovering this unique pump seal, we started supplying it pre-attached to our Lowara CEA(M) and Ebara CDX(M) brewery pumps, and we also stock the seal as a spare part for retrofitting to existing Lowara and Ebara pumps. This brewery pump seal has helped many of our clients forget about pump leaks and these common pump problems.

Find out more at www.whisperpumps.com or contact the Whisper Pumps technical sales engineers on 01777 871100.

Rawlings and Vigo merge

Rawlings and Vigo have merged to offer complete (end-to-end) processing and packaging solution.

The merger brings together Rawlings’ portfolio of primary packaging solutions and Vigo’s comprehensive processing equipment and consumables offering for clients in the premium drinks market, with expansion to deliver an end-to-end solution for premium food, health, and beauty brands.

The primary objective was to combine Rawlings’ expertise delivering off-the-shelf and bespoke glass packaging, graphic design, branding and decoration with Vigo’s tailored drink production systems, which include equipment, configuration, technical adaptions, installation, and full support from their team of engineers, providing clients with a complete packaging and production solution in one place. their existing offerings. Both Vigo and Rawlings will continue to trade at their existing premises and the same dedicated team and support remains in place.

Tom Wood, Managing Director of Rawlings, said: “We are excited to be joining forces with the Vigo team. There is a tremendous fit around people, values and purpose making this is a very natural and organic expansion. Both businesses will extend their capabilities to offer incredible value for our clients.” opportunities being a part of Rawlings brings. Joining forces allows us to take much bigger strides forward in capacity and offering than we would have been able to do so on our own. This will help drive increased value and range for our customers as well as strengthen our backup and support offering. Equally important, the culture and ethics of both businesses are closely aligned, and I have no doubt that the sharing of knowledge will further boost our offering.”

Find out more at www.vigoltd.com and www.rawlingsbristol.co.uk

S USTAINABILIT Y IN BREWING

Supplier Viewpoint

Waste not, want not

Independent waste broker Waste Source offers advice on procuring waste services…

Waste is simply lost resources. Managing them responsibly will build your businesses brand.

Waste is a valuable secondary resource and not something we just discard. Material has both a financial and environmental value and the benefit of avoidance is always going to be significantly more attractive than the cost of disposal.

When procuring waste services, the reality can sometimes fail to reflect this ambition. The problem really starts when businesses just think about the price to replace an existing service. This immediately focuses attention on the operation and input – rather than the desired outcomes. Climate change and the urgency to slow global warming has been pushed to the forefronts of our minds. Following the COP26 Summit, environmental action for businesses isn’t just a nice thing to do, it is critical to ensure your brand and business isn’t falling out of favour with your more ethically minded customer base.

There is an opportunity for businesses large and small to reflect on their waste, recycling and resource management performance and decide whether there is more that can be done.

Rather than thinking just about the operational need: How do we segregate, what type of bin do we need, who will be the cheapest supplier. Instead think more about the outcomes of what you want to achieve, whether it is 100% landfill avoidance, 90% recycling, incorporating reuse. This approach doesn’t only present a cost benefit (due to the shift away from expensive general waste), it also delivers improved environmental practice and carbon footprint.

An opportunity beyond the environmental one is the potential to build brand value through environmental effort. It is fantastic that more businesses are going to great lengths to improve their waste operation, but it is important to remember to leverage the opportunity to build a new and engaging dimension to their brand.

Find out more at www.wastesource.co.uk

Clearmark to tap into BeerX UK 2022 with automated print and apply labelling solution

After success at the show in 2020, pack labelling specialist Clearmark returns to exhibit at this year’s BeerX UK on the 16th-17th March at the Exhibition Centre Liverpool.

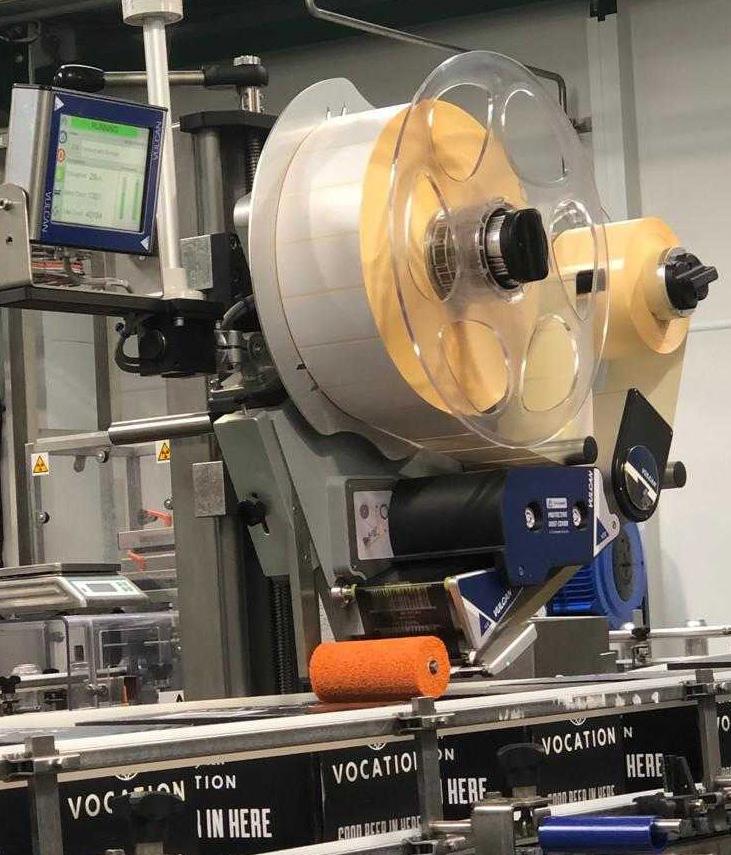

With proven results in the brewery sector with the ICE Vulcan Print and Apply Labeller, Clearmark is exhibiting this robust and versatile product on stand 149.

Expert engineers will give live demonstrations on the benefits to brewers this product provides and information on how to become GS1 compliant with print and apply labelling technology.

Over the past year, most businesses have seen an increase in staff shortages and supply chain issues meaning that automating the packaging line is now more important than ever. With easily customisable label design and the ability to print and apply up to 150 packs per minute whilst never missing a pack, the ICE Vulcan Print and Apply Labeller quickly provides a great ROI to craft breweries who have ever changing product lines. Breweries can benefit from increased speed, reliability and freeing up operators to perform more value-added tasks.

With many breweries now tapping into grocery shopping market, it is important for products to be labelled with correct and clear information in order to avoid costly fines. It is imperative the labelling solution can not only quickly and accurately apply labels to kegs, casks and bottles, but also has the ability to rapidly change labels to fit product changeovers as needed.

The Clearmark team are on hand to chat to visitors at BeerX UK about success in the industry with the most recent application at Vocation Brewery.

With Vocation’s sales soaring, 51 new product lines, and their beers making way onto supermarket shelves, they needed a solution to automate the labelling process whilst also complying with the new GS1 regulations. Dan Tasker, Packaging Manager at Vocation, said: “Everything sent to the retailer has to be boxed and labelled. We produce about 30 pallets a day, with 100 or 200 cases on each pallet. Anything other than our core brand has to have a custom label on it. Since automating our labelling process we’ve had zero defects - the ICE Vulcan print and apply system is 100% fool-proof and in hindsight we should have automated sooner.”

For all pre-event enquiries, give the Clearmark team a call on 01159 640144 or email enquiries@uk.interactivecoding. com or visit www.clearmark.uk

New beer analyser BeerFoss FT Go adds data to the brew

Analytics specialist Foss Analytics has launched a new beer analyser called the BeerFoss FT Go which has found favour among craft brewers such as Amager Bryghus near Copenhagen.

The brewery’s first encounter with the new solution was when it was put on trial as an alternative to existing test methods. These were diverse, labour-intensive and prone to human error. For instance, it was often necessary to take a whole litre of sample from the wort to get a density measurement and this would involve degassing the sample in just the right way before it can be tested. Alternatively, sending out tests to an external laboratory involved waiting time for results and high running costs.

In contrast, the new solution covers essential brewing parameters in one simple test on wort, beer under fermentation or finished beer. Parameters include alcohol, real extract, pH combined with overview parameters for easier batch tracking. The test takes around three minutes.

No degassing is required and filtering is only limited to special sample types. The risk of variations in samples and operator error is also reduced by the simplicity of being able to just take a sample directly from the tank, bottle or can. The instrument selfcleans its measurement flow system and it requires only minimal use of consumables. It is delivered ready-for-use with first time set-up taking less than two hours.

More information about BeerFoss FT Go can be found at www.fossanalytics.com/en/products/beerfoss-go

Close Brothers Brewery Rentals launches EkegPlus

The latest addition to the Close Brothers Brewery Rentals product portfolio is EkegPlus, which allows customers to collect and refill from its fleet of orange banded EKegs and ECasks and deliver them directly to venues as well as through approved wholesalers.

This flexibility gives customers increased control, with the added benefit of only paying for containers when they’re being used. The technology driven combination of bulk scanning equipment and the PlusPortal management platform offers brewers live cycle data, transparent billing, and informative insights to reduce costs and streamline operations. Close Brothers Brewery Rentals provides a wide range of services in addition to longer term container rental, including fee-per-fill short term rental containers ECasks and EKegs, as well as repair and refurbishment services and equipment finance. Close Brothers will be at BeerX UK this year in Liverpool on March 16th and 17th on stand 80.

For more information go to www.closebreweryrentals.co.uk

Canning technology specialist Core Equipment looks at how its latest canning system addresses common concerns over sealing…

The start of 2021 brought significant change to the way in which breweries operated, with many brewers looking to diversify their business models to cope with new pressures and drive sales.

Typically packaged in keg or bottled formats, many breweries across the UK switched to canning. The compact design and need for less space allowed for more product to be delivered and offered more commercially viable options for those who have a high turnover of product at a lower price point.

Cans are known for offering the producer versatility in product sizes from 150ml slim to 500ml standard whilst addressing consumer issues such as sustainability and portability. However, the most important concern for producers when packaging a beverage is preventing contamination from the exposure to oxygen, reducing shelf-life and modifying taste.

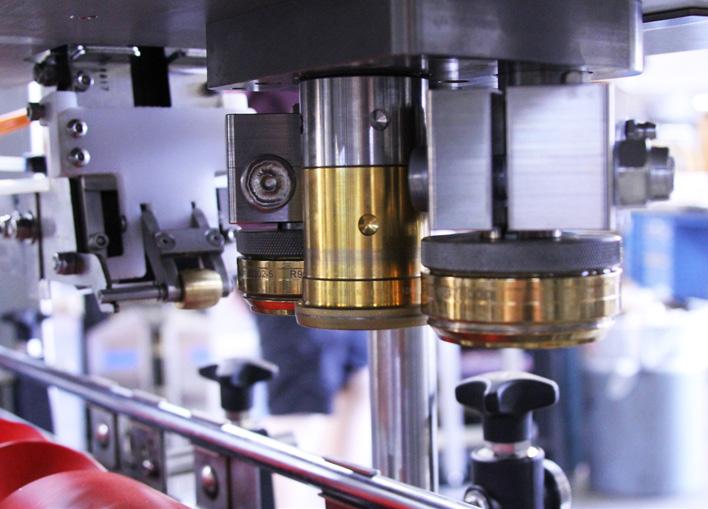

Successful developments in scaling down counter pressure technology have made this equipment available to craft producers at an affordable price. Exclusive suppliers of the CODI counter pressure system, Core Equipment introduced this technology to the UK and Europe and continues to be the only distributor of this equipment.

Preventing contamination from bacteria through exposure of oxygen means the technology in sealing is the most critical part to any canning machine.

Made from 316 stainless steel, the mechanically driven seamer rollers in the CODI system work in conjunction with the can lifter. This pneumatically driven piston enables the rollers and can lifter to work simultaneously, as the moving parts lock into position to give the correct spring pressure connecting the lid and body of the can, creating a consistent seam every time in comparison to that of a linear-motion method. This double seam creates an airtight seal, protecting the liquid and ensures durability from pressures generated in the can during transportation.

For an oxygen-sensitive product this counter pressure canning machine keeps the dissolved oxygen pick up level to as low as 10ppb, effectively stopping the consequences of oxidation from the beginning. The integrated “bubble breaker” in the seamer additionally blankets the can with CO2 before the lid is applied, rapidly dissipating foam to eliminate oxygen in the headspace of filled cans, keeping this consistency along the whole filling process.

Additionally, the CODI CCL-45 seamless counter pressure technology enables the user to have complete control over the atmospheric conditions across the entire filling process, meaning the single head seamer achieves speeds of up to 55 cans per minute, with some customers filling upwards of 30,000 cans per day whilst capturing the intended taste with no environmental compromises.

Yes you can!

Supplier Viewpoint