3 minute read

Otto’s Column

from Mt. Morris Times

by Shaw Media

LOCAL HISTORY Purington Pavers used on first hard surface roads

Editor’s note: Otto Dick, Oregon has researched the people, places and events important in the Oregon area’s history for the Ogle County Historical Society. The following is one of a series of the articles he has written.

BY OTTO DICK

The first hard-surfaced roads in the Oregon Business District were constructed of brick manufactured by the Purington Brick Company located near Galesburg, Illinois.

Today you can drive on a section of a Purington Brick road located on Brick Road at the northwest corner of Pine Rock Township.

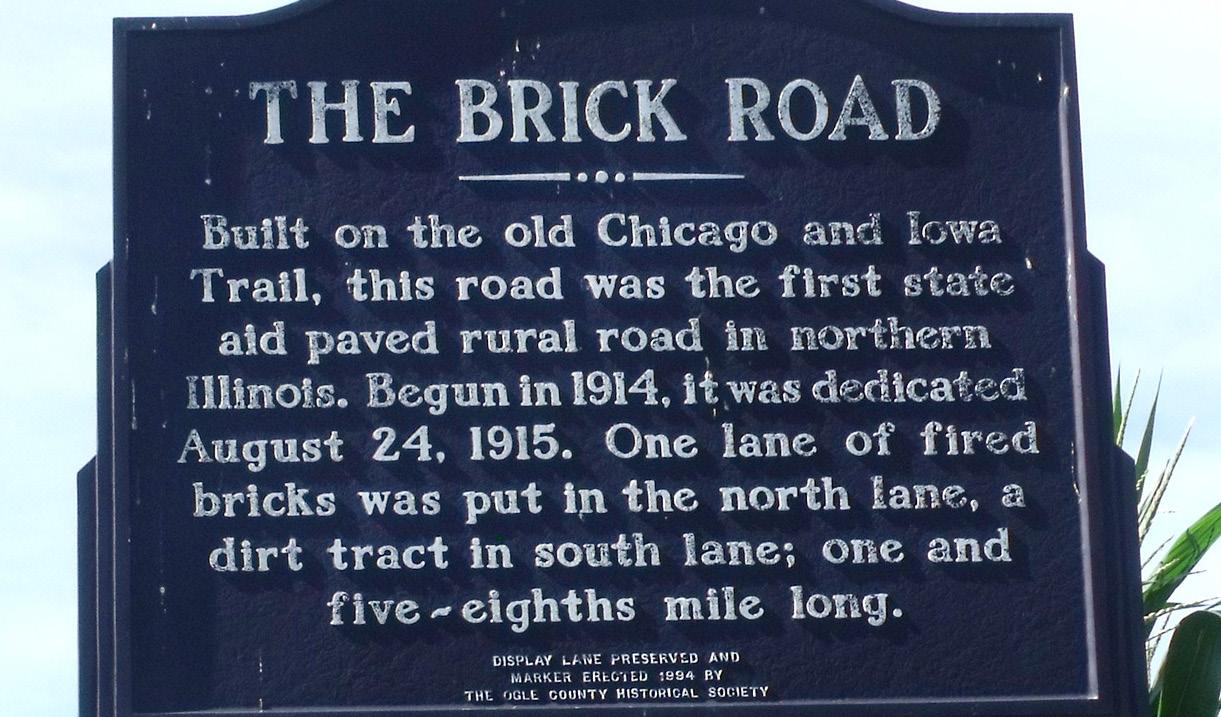

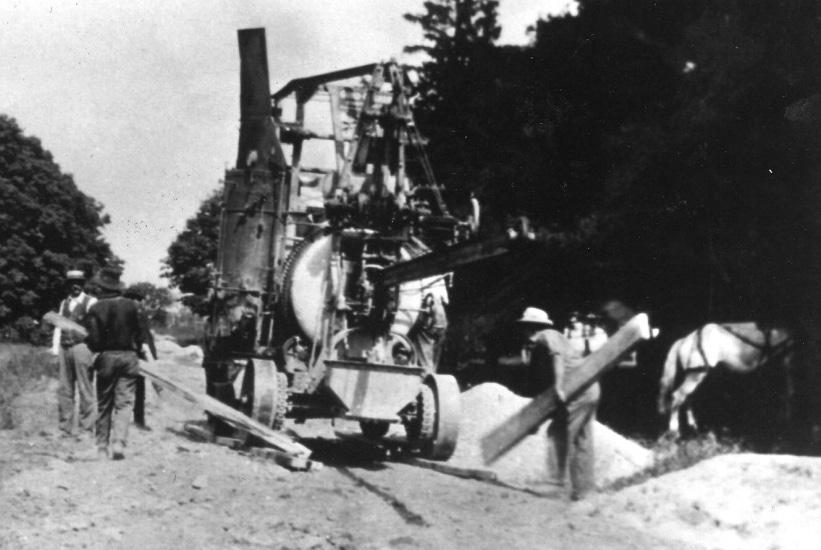

The Brick Road plaque located by the restored section of this road reads as follows: “Built on the old Chicago and Iowa Trail, this road was the first state aid paved rural road in northern Illinois. Begun in 1914, it was dedicated August 24, 1915. One lane of fired brick was put in the north lane and a dirt tract in the south lane one and five-eighths mile long.” In Oregon Purington Bricks are located in the parallel parking area ABOVE: Purington Pavers were used in the first hard-surfaced roads in Oregon. These pavers can be seen in front of Conover Square. MIDDLE LEFT: Lois Carpenter Cline (left) gives the Brick Road History at the 1994 re-dedication. MIDDLE RIGHT: A small strip of Purington Pavers can be seen on Brick Road, east of Oregon. BOTTOM: This 1915 photo shows bricks being laid on the Brick Road. Photos supplied by Otto Dick at Conover Square and the brick sidewalk south of the depot.

It’s appropriate these bricks are also located at the Oregon Depot because our CB&Q Railroad played a major role in the distribution of Purington Pavers. The CB & Q Railroad provided access to the world by building a switch track extension to the brick yards near Galesburg.

This track was essential for the success of this business. These heavy brick could then be transported efficiently by rail.

Before the manufacture of road pavers were available, Midwestern communities were waiting for a solution to the spring and fall mud roads. In the dry seasons communities were cleaner and healthier as a direct result of paved roads.

By 1895 Purington Bricks was the the kiln. largest manufacturer of paving bricks Teenage boys were hired as “sand monproducing 75 million bricks annually. keys” who threw sand on the bricks so Eight hundred workers were employed they wouldn’t stick together in the kiln. producing over 150,000 bricks per day. The bricks were heated in coal-fired

The Purington Company produced the kilns to the point of vitrification, a chem4”x4”x 8” bricks until 1949. They began ical reaction that caused the brick to with Yard 1 containing 14 kilns, and later become extremely hard and durable. The added Yard No. 2 with 22 kilns. kilns then had to be cooled and cleaned

Making bricks was a labor intensive between each firing. process. The shale was scooped out of A minor league baseball team called nearby pits, mixed, crushed, dampened the Galesburg Pavers existed from 1890 and molded into raw, green colored bricks. to 1914.

The bricks then had to be set by hand We are fortunate to have photos of the onto large, movable platforms. A green brick streets at the intersection of Rt. 2 brick “pitcher” tossed the clay bricks, and Rt. 64. sometimes two or three in each hand to The historic Purington Pavers are the catcher above who stacked them in available on the internet.