32 minute read

Checkoff Report

Investments Made by Growers for the Future of the Peanut Industry.

Reports from the: Alabama Peanut Producers Association, Florida Peanut Producers Association, Georgia Peanut Commission & Mississippi Peanut Growers Association

APPA promotes peanuts to Alabama beachgoers

With Alabama beaches back open, the Alabama Peanut Producers Association wanted to be sure beachgoers got the message to eat more peanuts. Partnering with National Peanut Board through co-promotion funds and design assistance from Golin, APPA placed three digital billboards on Alabama Highway 59 – the most traveled route to Gulf Shores and Orange Beach.

The message “Peanuts – America’s favorite beach snack. Filling. Nutritious. And easy to pack,” was posted for four weeks, June 15 – July 12, 2020, for south bound traffic to see. This campaign garnered approximately 1.0 million impressions.

The Alabama Peanut Producers Association billboard attracts tourists traveling to Gulf Shores or Orange Beach area on Alabama Highway 59.

Georgia Peanuts promoted on Southern Ag Trailers

The Georgia Peanut Commission sponsored the printing and installation of peanut promotion decals, which were installed on seven trailers owned by Southern Ag Carriers. The messaging used the Georgia Peanuts logo and the humble peanut’s recent Superfood status to promote peanut consumption among consumers. The Georgia Peanut Commission’s website was also included.

The trailers will be used throughout the United States and have the potential to generate more than 600 visual impressions for every mile driven (according to the American Trucking Association).

APPA exhibits at the Virtual Meeting of the Alabama American Academy of Pediatrics

After postponing their spring meeting due to the COVID-19 pandemic, the Alabama American Academy of Pediatrics hosted a virtual meeting and pediatric update on June 13-14, 2020. The Alabama Peanut Producers Association participated in a Virtual Exhibit Hall by sharing early introduction of peanuts information and guiding participants to the PreventPeanutAllergies.org website.

APPA also gave away a goody basket of early introduction products through a virtual door prize contest. Approximately 80 pediatricians and staff attended the virtual meeting.

Georgia Peanut Commission sponsors Georgia FFA

The Georgia Peanut Commission and the Peanut Institute teamed up to sponsor the Georgia FFA Star in Agriscience Award during the virtual Georgia FFA State Convention held May 28-29, 2020. The State Star in Agriscience Joseph Corbett, Award was presented Georgia FFA Star in to Joseph Corbett of Agriscience State Lowndes County FFA. Winner The additional state finalists included Adonis Merritt, North region winner from Newton College and Career Academy and Maddie Riggins, Central region winner from Pike County.

Jordan Jacobs, parts salesman at Lasseter Tractor Company, hands over a part to Mark Roberts of Moultrie, Ga. Lasseter Tractor Company has set up a barrier for customers to remain at least 6 feet apart when picking up items at the store counter.

Working through a

PANDEMiC

Working from home and social distancing has become normal in the workplace the last few months due to COVID-19. For those involved in agriculture, this has not been normal. Farmers and those involved in agriculture have still worked, but in a different way. The personal one-on-one conversations at the farm, handshakes and tractor rides may have slowed down or come to a halt.

Additionally, meetings, field days, fairs and festivals have been canceled. These events have all had an impact on those involved in agriculture, an industry that thrives on customer relationships and personal interaction.

“The greatest impact COVID-19 has had on work is the inability to conduct and attend meetings and conferences,” says Brendan Zurweller, Mississippi State University peanut agronomist. “Several meetings from county, state and national level have been canceled. The annual APRES (American Peanut Research and Education Society) meeting has also changed to a virtual format for this year.”

However, research projects on peanuts have not been canceled or halted across the Southeast.

“Even during the lockdown, essential research activities with time sensitivity such as agriculture were allowed to continue at Mississippi State University with certain social distancing practices being implemented,” he says. “Other research activities such as grant writing and manuscripts preparation/submission continued as normal from the home office. We are now in our second phase of re-opening and reporting to the work office when not in the field.”

Research may have got off to a slow start with many unknowns on what was allowed, but once the paperwork and approvals were finalized, research continued almost like normal years.

“COVID-19 has definitely slowed the normal activities and changed how activities are conducted at the University of Georgia as a whole over the last three to four months,” says Scott Monfort, University of Georgia Extension peanut agronomist. “The one vital thing that has not changed is the commitment of the Extension Service to the growers in Georgia. Both agents and specialists have continued to serve its agricultural clientele during the pandemic. This has

been extremely important as peanut growers have gone through a very rough planting season just to get adequate stands.”

Communication is the Key

Even though meetings were canceled, the ability to continue a conversation with customers has not been halted. Communication has been different though without the face-to-face interaction in some cases.

According to Lee Prather, senior retail sales representative with Syngenta, the pandemic has helped him to be more efficient in planning. He is used to being on the road visiting farmers and retailers. However, the pandemic slowed his travel and required him to use the phone, email and text more. He also had to plan more visits with farmers and retailers instead of just showing up.

He is used to walking up to farmers and shaking hands. However, the harsh reality set in when he realized he can’t continue to shake everyone’s hand or even ride in the truck or tractor with the farmer.

Company policy at Syngenta currently doesn’t allow Prather to ride in a vehicle with another farmer or even let a farmer ride in his work truck.

“Everyone is trying to be cautious,” Prather says. “I haven’t stayed in a hotel in 115 days, but my time driving in my truck has increased to 300 plus miles per day.” His sales area includes retailers from Augusta to Unadilla, Georgia.

Prather even thinks the pandemic has helped farmers be more efficient too.

“I have noticed more farmers stocking up on chemicals they need for the entire season,” he says. “Everyone was nervous about the unknown, so with acres up, farmers planned more in advance.”

The key, according to Prather, is communication and not going radio silent with farmers and retailers during the early stage of the pandemic. To help with communication, Syngenta created a

Josh Hood, road technician with Lasseter Tractor Company in Tifton, Ga., works on his computer to remotely diagnose a sprayer issue in McRae, Ga., through the John Deere Mobile Telematics Gateway. The program has allowed Hood and others with John Deere to correct any issues remotely while keeping the farmer and dealership staff safe and healthy.

Carlton Self, Tifton Store Manager Lasseter Tractor Company

biweekly newsletter distributed to farmers and retailers through email. According to Prather, the newsletter wasn’t aimed as a sales pitch, but a way to keep the lines of communication open by sharing agronomic tips for the season.

In addition to Syngenta, tractor dealerships had to find ways to communicate with their customers too.

“As with all business, COVID-19 has presented many unique challenges that we’ve had to adjust to,” says Carlton Self, manager of Lasseter Tractor in Tifton, Georgia. “We have to offer a high level of customer support and a differentiated customer experience in an environment where our face-to-face interactions have been limited out of necessity in an effort to protect our customers and employees.”

As a John Deere dealer, he says a large part of their business comes in the form of customer support, through parts and equipment service. So, Lassester Tractor Company started using more curbside pickup, deliveries and drop locations for their parts service.

Since COVID-19 restrictions coincided with planting season, which is a very busy time for tractor dealerships, Self says they were able to utilize more remote diagnostic capabilities to address issues with tractors in the field.

“This helped reduce face-to-face interactions, while still allowing us to make repairs in a timely manner,” Self adds. “Agriculture is a highly personal business though, and we want to make sure we are doing our best to continue to grow our relationships and provide a high level of service. With that, there will always be the need to go and see folks face-to-face, and we just want to make sure we are doing our due diligence to protect them and to protect ourselves.” t

THRiVE

WiTH Peanuts

SCHOOL SNACK COULD HELP STUDENTS iN AFRiCA, CREATE MORE DEMAND FOR PEANUTS

Photo credit: Mark Manary, Washington University. T he World Food Programme (WFP) plans to invest $1.75 billion a year over the next decade in school feeding programs, and the Feed the Future Peanut Innovation Lab at the University of Georgia College of Agricultural and Environmental Sciences is working to see how peanuts might provide the protein, minerals and micronutrients those kids need to thrive.

“We zeroed in on the potential for school feeding several years ago as a way to reach hungry kids, so we’d already put a lot of thought into how to go about it,” says Jeff Johnson, a retired executive with Birdsong Peanuts who serves on the External Advisory Committee for the Feed the Future Innovation Lab for Peanut.

In a plan called Decade of Action, WFP plans to ensure that school-aged children around the world receive adequate nutrition through school meals and snacks by 2030. Making children healthier is an important goal, but the WFP also makes the point that healthy children do better in school, maximizing the impact of billions of dollars spent on primary school education.

Because peanut is nutritious, relatively inexpensive and shelf stable, the nut already is the main component in Ready-to-Use Therapeutic Food to help children recover from severe malnutrition and in supplementary foods to prevent malnutrition. Numerous studies show cognitive benefits to people who consume nuts; research currently under way through the Peanut Innovation Lab could directly show that eating peanuts can help children succeed in school.

“We’ve been working on feeding in Africa for 15 years strictly from a humanitarian standpoint, but if the World Food Programme is going to spend $50 billion and completely change the foodaid trends in Africa, they are going to have to have a lot of product,” Johnson says. “We think peanut products are the only thing that can be done as conveniently and inexpensively and in the volume that will be required.”

Birdsong Peanuts and the National Peanut Board each are investing through the Peanut Innovation Lab in a research project in Ghana to evaluate the effectiveness of a school snack developed by Washington University’s Mark Manary.

Many students in Ghana, like

children in other low- and middle-income countries, receive sporadic school meals, but they are starchy and may not contain the best ingredients to help a hungry child grow and concentrate in class.

Manary, one of the key inventors of the peanut-based therapeutic food that’s become the standard for emergency feeding, is producing and testing a peanut-based snack with students in northern Ghana to gauge the effects on physical growth and cognitive learning.

He is working with Matilda SteinerAsiedu, a nutrition professor and dean of the School of Biological Science in the College of Basic and Applied Sciences at the University of Ghana.

The four-year project is funded with $500,000 from the Peanut Innovation Lab, $100,000 from Birdsong Peanuts and $100,000 from the National Peanut Board, a research, marketing and promotion organization supported by the 7,000 American peanut farmers.

In the randomized clinical trial, 750 kids ages 6 to 9 will eat one of three school snacks: a peanut-based food, the same peanut-based food with milk included, or a snack made with a local tuber or cereal. At the end of the school year, the students will be measured for height and change in cognitive testing. All the snack formulas will include the same supplemented micronutrients.

“The results will help determine whether the power of the peanut, which has been such a game changer in other food aid products, can be channeled to school age children as well,” Manary says.

Feeding one meal a day and providing basic health interventions to 73 million primary school children in the world’s poorest countries would cost around $5.8 billion a year, the WFP estimates, but the return on the investment is 20 times the cost.

While WFP just announced the 2030 School Feeding Strategy, the Peanut Innovation Lab many months ago began to explore the possibility of partnering with Birdsong Peanuts and the National Peanut Board to research a school snack, knowing that the project could benefit both African students and U.S. farmers.

“The (National) Peanut Board has always been humanitarian-minded and forward-thinking. This seemed like a natural fit. We’ve been talking about this for quite some time,” Johnson says.

“We appreciate the opportunity to partner with the Peanut Innovation Lab and Birdsong Peanuts to possibly give millions of children a brighter future,” said Bob Parker, president and CEO of the National Peanut Board. “Our farmers take great pride in producing a nutritious and wholesome food product. Peanuts are an ideal food for such a program because of the shelf stability, cost and familiarity with African children.”

While African farmers with help from national programs and the Peanut Innovation Lab are making strides to increase yield and improve quality, they currently produce only a fraction of the demand that would be created by a sweeping plan to feed school children across Africa.

“If the World Food Programme and partners are going to spend $50 billion, that’s a game-changer. This has huge implications. It’s going to take a while to get there, but there will be opportunities for U.S. growers and manufacturers,” Johnson said.

He predicts that peanut-based products for African students might be made in a combination of ways – in Africa with nuts grown in Africa, in

Since peanuts are nutritious, relatively inexpensive and shelf stable, the nut already is the main component in Ready-to-Use Therapeutic Food to help children recover from severe malnutrition and in supplementary foods to prevent malnutrition.

Africa with nuts grown in the U.S. and in the U.S. with nuts grown in the U.S. Feeding the 73 million children in need of better nutrition would require all three. t

BYALLISONFLOYD UNIVERSITY OF GEORGIA

2020 HARVEST GUIDEBOOK

Maintain Equipment Prior to Harvest

Preparing for peanut harvest cleaning adjustments to see that they acres, they may need to be changed every by checking equipment in move freely along with inspecting the 10-15 acres if the weather turns dry,” advance can help a farmer cleaning fan and cleaning out any trash says Jason Morris, KMC director of save time and money in the buildup. engineering. “Research has shown long run. “In regards to combines, too many matching conveyor speed to ground speed

Scott Monfort, University of Georgia operations wait until the last minute to is critical, so be sure to check the Extension peanut agronomist, get their combines out from under the tachometer on the digger to make sure it recommends for farmers to be sure to shelter for the new harvest season and is in good working condition. Tachometer check all equipment prior to the start of then realize that they needed to make kits can be added to older model diggers harvest. certain repairs from the previous harvest to improve their performance.”

“Harvest is a busy time and we don’t and get really pressed for time to do so,” In addition to checking equipment want anyone having downtime due to Mathis says. “It is a good idea to start prior to harvest, being safe on the road things that could have been checked inspecting all harvesting equipment during the busy harvest season is also before this critical time when you have several weeks ahead of time in case items important. many early mornings and late nights,” for repairs need to be purchased.” “For safe transport on roads, be sure Monfort says. In addition to checking equipment in all flashing lights on the tractor and on

Mark Mathis, Southeast agricultural advance, farmers also face issues with the implement are operating correctly,” sales manager for Amadas Industries, replacing peanut digger blades during the says Bennie Branch, president of Kelley recommends inspection of all drive chains harvest season. Manufacturing Co. “Also, make sure the and sprockets, all belts, shaft bearings and “Soil moisture plays a big role in the tractor to implement connection is in gearboxes. Additionally, he recommends life of a peanut digger blade. In fields good condition.” t for farmers to inspect all picking and where peanut blades typically last 40-50 BYJOYCROSBY

Harvest Equipment Checklist

Peanut Digger

Pre-harvest Checklist u Check the entire machine for loose or worn parts. u Make sure the plow shanks are not bent and the digger blades run level. u Straighten any bent rattler bars. u Check all bearings and the gear box oil level. u Check coulters and vine cutters for proper location and condition. u Align the inversion rods before digging (see operator manual for proper spacing). u Check for binding or unusual noises by operating the machine briefly. u Have plenty of extra digger blades on hand.

Harvest Season Checklist u Check digger blades for proper sharpness and depth. u Coulters should cut vines leaving no clumps. u Check the flow of material through the digger. Make sure ground speed is synchronized to produce a smooth flow of vines and soil into the digger. u Make sure drive belts are tight. u Check for proper vine inversion and inversion rod spacing.

Combine maintenance checklist

Pre-harvest Checklist u Clean inside and out, removing all dirt and residue from the previous crop. u Check for loose, bent, broken, or missing parts such as pickup springs, cylinder springs and stripper springs. u Check air lift ducts for holes, lodged objects and dirt buildup. u Make sure all shields are functional and in good shape. u Replace the “Slow Moving Vehicle” sign if it is not in good condition.

Harvest Season Checklist u Adjust settings according to windrow conditions. Remember, no combination of settings will remain optimal throughout a given day. u Check combined peanuts periodically for LSK’s and foreign material. u Check chaff passing through the combine for excessive pod loss. If problems occur, adjust stripper spring settings.

There are many factors that can result in replanting peanuts which ultimately impacts the decision on when to harvest. In 2020, farmers have been impacted considerably more by Aspergillus niger which has caused a reduction in plant stands after emergence in some areas.

According to Scott Tubbs, research agronomist at the University of Georgia, there are many factors that can result in a sub-optimal plant stand. These factors include using poor quality seed, improper calibration or operation of planting equipment, unsatisfactory soil conditions, deficient adherence of seed treatment, feeding by insects, hogs, or other pests, and rapid temperature fluctuations.

So, when farmers keep the original plant stand and add additional seed to the field in an adjacent row several weeks after the initial planting determining when to dig can be difficult.

“Harvesting at optimum maturity is tricky in peanuts, even under normal conditions and uniform plant stands because of the indeterminate growth habit of the crop,” Tubbs says. “When a supplemental replanting occurs, this exacerbates the determination of the most optimum timing for crop termination.”

Essentially there are two crops of peanuts growing simultaneously, and digging should be timed in a way that the later planted peanuts have a chance to catch up in maturity. However, farmers do not need to wait too long and risk losing too many of the most mature pods from the initial planting from either weak pegs or sprouting on the vine.

According to research by Tubbs at the University of Georgia, the timing of termination/digging should be at least an average between the maturities of the initial planted peanuts and the replanted peanuts, up through the maturity of the replanted peanuts.

“If digging coincides with only the maturity of the initially planted peanuts, then the replanted peanuts will remain immature to the point that yield and grade of the entire crop will suffer,” Tubbs adds.

To ensure optimum maturity between the original plant stand and replanted peanuts, growers should collect samples that represent a proportion of plants from each plant timing and utilize the hullscrape maturity profile/pod blast method to determine optimum digging timing.

As an example, if 60 percent of the plants in the field are survivors of the initial planting and 40 percent are from the replant, then Tubbs recommends taking about 6 original plants and 4 replanted plants that are average size for the field, for the assessment.

Tubbs suggests that farmers take the entire plant to the Extension office and do not remove the pods ahead of time. This will ensure proper sampling by removal of all pods from each plant being used - no partial plants or incomplete pod removals; and using an appropriate number of pods for the maturity board sample.

According to Tubbs, too many or too few will bias the results

“It is difficult to delay harvest activities. But in the event of a replanted field, it can pay dividends to be patient and allow the crop to remain in the ground longer than normal to give ample opportunity for maximized maturity,” Tubbs says.

As long as the vegetation remains healthy, a field with replanted peanuts will often need to remain in the ground an additional 10-14 days longer than a uniformly planted crop, he adds.

“The gains from the replanted plants offset the losses of a few overmature pods from the initially planted plants,” Tubbs says. t

Using Remote Sensing to Map In-Field

Variability of Peanut Maturity

Peanut growers face a challenge every year as harvest season approaches –the decision for the best digging time to achieve optimum pod maturity. Pod maturity is not uniform within plants or within the field, and the decision on when to dig is generally based on methods that are subjective and do not reflect the spatial variability of maturity at the field scale.

In addition, variability in soil type within a field is not unusual, which can lead to varying plant growth and pod development, which results in inconsistent pod maturity. A method using remote sensing to predict peanut maturity at the field scale as well as the variability in maturity within the field is being evaluated by University of Georgia researchers George Vellidis and Cristiane University of Georgia Plant Physiologist Cristiane Pilon and Ph.D. student Chiara Rossi measure Pilon. leaf photosynthesis and collect samples for leaf pigment content. The relationship between

The research has been conducted physiological data and peanut maturity is evaluated. since 2018 using research plots from UGA farms and irrigated and dryland grower fields. Historical satellite images of the fields are analyzed to select blocks within grower fields with the most soil variability each year.

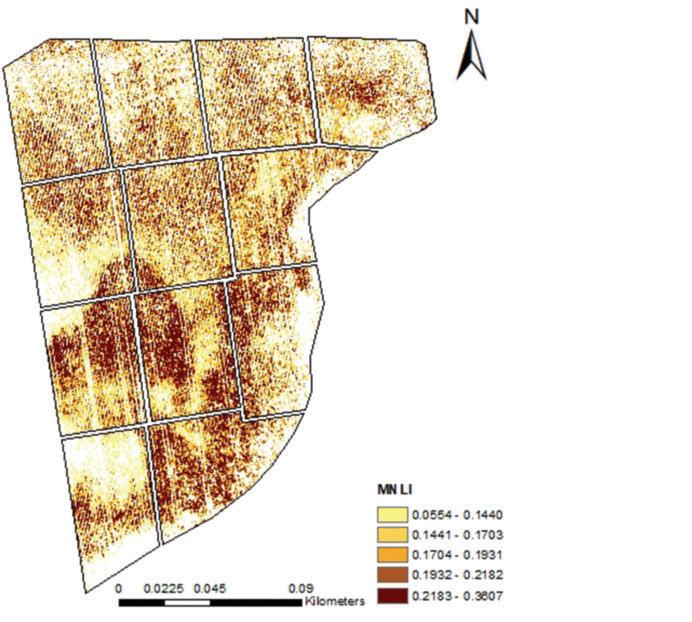

Starting at peak flowering, a camera mounted on a UAV is used weekly to capture multispectral images of the fields. On the same days, physiological and growth measurements are collected to An RGB image of a grower’s irrigated field in Calhoun County in 2018. The block was divided into 33 grid cells. Vegetation index (NLI) image of a grower’s irrigated field in Calhoun County in 2018. The block was divided into 33 grid cells for assessment of peanut maturity. Red indicates assess plant status and track plant development. premiums that might be offered for more mature peanuts and blue indicate less mature peanuts.

When the plants start forming pods, optimal maturity and quality. Finally, we plants are destructively collected and pods will develop recommendations of how are classified into different maturity these tools can be used by peanut growers classes based on mesocarp color by using to improve overall quality and yield of the Peanut Profile Board. The Peanut their peanut crop. Maturity Index (PMI) is then calculated The research results from the past for each sample. Vegetation indices (VIs) two years are very promising. The are obtained after processing all multimeasurable outcomes of this project will spectral images and the relationships be knowledge on how to utilize remotely between VIs and PMIs, plant physiology sensed data to develop spatial maps of and growth are generated. peanut maturity prior to digging. This

The goal is to identify one or more knowledge will allow growers to estimate VIs that can be used to accurately predict the variability of maturity of their peanut peanut maturity at field scale. The research will also quantify the economic advantage of differentially digging and harvesting peanut fields based on crop. t BYDR. CRISTIANE D R. GEORGE UNIVERSITY OF PILON& VELLIDIS GEORGIA Vegetation index (MNLI) image of a grower’s rainfed field in Berrien County in 2019. The block was divided into 12 grid cells for assessment of peanut maturity. Lighter areas indicated more mature peanuts and darker areas indicated less mature peanuts.

Determining Optimum Peanut Maturity

Determining when to harvest relies on taking a random representative factors including the number of acres to be is one of the most sample of peanuts from a field, then harvested, equipment availability and important decisions scraping off the outer layer of the peanut capacity, labor availability and impending growers make each year. hulls. The inner hulls will show a range of weather conditions. The peanut maturity impacts yield, flavor, colors, from white to black. The darker the Brendan Zurweller, peanut agronomist grade and shelf life. Research has shown color, the more mature the crop. at Mississippi State University, suggests that peanuts harvested too early or too late Hulls that are white or yellow are for farmers to approximate the minimum can have reduced yield by 500 to 700 immature. Those that are orange to brown number of days it’s going to take to pick pounds per acre. are close to maturity. The dark brown hulls all the peanut acreage based on their

“There are numerous factors that are mature and the black hulls are either harvest capacity and how spread out the affect when to harvest individual fields,” mature or a bit over-mature. Once the plant dates are. says Scott Monfort, University of Georgia outer layer is removed an inner hull color “I think this really helps to be Extension peanut agronomist. “Farmers is exposed, the peanuts are arranged on practical about how early one needs to can plant the same variety on the same day the maturity profile board by color to begin digging and how many acres they in different fields and the peanuts may determine the optimum digging date. should dig at one time,” he says. t still mature at a different rate due to soil Farmers also have to weigh out their type differences, climate and weather options on when to harvest due to several BYJOYCROSBY differences and pest problem differences. Checking each field individually is also Peanut Hull Color Groups & Characteristics important since the peanuts may not mature in the order in which they were Major color Characteristics Development period (days) planted.” One of the best ways to determine White Soft, watery, poorly defined kernel, between the size of a match head and a full size pod 14-16 crop maturity is through the hull-scrape method or pod blasting and using the peanut profile board. The hull scrape Yellow Spongy texture, pod is full size, kernel is somewhat defined 10-14 method is based on color changes in the Dark Yellow Coarser pod texture then yellow, well-defined kernel 10-14 middle layer of the peanut hull as the nut Orange Pink seed coat developing 12-14 matures. Brown Rough pod texture, dark pink seed coat 10-12

In essence, the hull scrape method Black Completely developed kernel, extremely rough pod texture 19-21

KMC Releases New 74 Series Combine

Farmers will have a new option this fall with the new Kelley Manufacturing Co. 74 Series Peanut Combine. The 6-row combine was developed largely through farmer input.

KMC introduced the combine last fall during the Sunbelt Ag Expo in Moultrie, Georgia, and provided it has an option to winners of the Grand Door Prize at several peanut farm shows in 2020.

The 74 series combine is available as a 6-row or 8-row (30” row) option with the unload on the go option too.

The combine features several key changes including: • Hydraulic separator fan direct drive stemmer/screens into two separate • Concaves are supported from side option (No belts). systems. Also new shaker pan is over 20 frame with adjustable bolt on bushings • New cam shaft design instead of percent lighter weight. instead of rod across entire machine eccentrics (Driven on one side, 2 3/16” • No rocker shaft/rocker bearings. connecting two concaves together. shafts with no center support bearings). • Hex rollers added to cleaning For additional information on the new • Reduced loads on push arms by section. combine, visit www.kelleymfg.com or call splitting the shaker drive and • #1 concave swings open with quick 229-382-9393. t release latches.

USDA NASS Releases Planting Acreage Report T he USDA National Agricultural Statistics Service has released it’s June 30, 2020, Acreage Report. For peanuts, the U.S. 2020 planting estimate is 1,514,000 acres. Area Planted Peanut Area Planted - States and United States: 2018-2020

Following up to the Prospective Plantings report State 2018 Final 2019 Final 2020 June released in late spring, NASS surveyed nearly 71,000 farm operators during the first two weeks of June to (1,000 acres) (1,000 acres) (1,000 acres) gather information on what farmers actually planted. Alabama 165 160 170 Georgia continues to lead planted acreage at 710,000 acres followed by Texas at 180,000 acres and Alabama Arkansas 26 34 35 and Florida at 170,000 acres. Florida 155 165 170

Total planted acreage for the Southeast (Alabama, Georgia 665 670 710 Florida, Georgia and Mississippi) area is 1,075,000 acres, Southwest (Texas, New Mexico and Oklahoma) Mississippi 25 20 25 area is 197,000 acres and the Virginia Carolina area at New Mexico 5.5 4.7 5 207,000 acres. North Carolina 102 104 105 In other crops, NASS estimated 92.0 million acres of corn planted in the United States for 2020, up 3% Oklahoma 16 15 12 from last year. Soybean area planted is estimated at 83.8 South Carolina 87 65 75 million acres, up 10% from last year. Cotton acreage Texas 155 165 180 planted for 2020 is estimated at 12.2 million acres, 11 percent below last year. Wheat acreage is estimated at 44.3 million acres, down 2 percent from last year. This Virginia United States 24 1,425.5 25 1,427.7 27 1,514 represents the lowest all wheat planted area on record Source: 2018-19 - USDA’s National Agricultural Statistics Service Crop Production since records began in 1919. t Summary, Jan. 2020. 2020 - USDA’s National Ag Statistics Service June 30, 2020 Acreage Planting Report.

The National Peanut Board has funded production research projects to increase efficiencies for farmers since 2001, totaling more than 1,600 projects and $37 million. Now, NPB is taking its commitment to research one step further with the launch of the new Production Research Database, at nationalpeanutboard.org/more/productionresearch-database. PeanutResearch.org NPB is giving unprecedented access to research projects involving the Board’s funds. Within the database, growers and industry members can learn more about research on a specific topic—from breeding and genomics to pest and disease control—region, year and investigator. “The Production Research Database is a fantastic resource for growers, extension agents and researchers,” said Dan Ward, National Peanut Board N.C. board member, former chairman and research committee chair. “For growers, it is not only a clear way to see where research dollars are going, it’s also easy to use and access from the field. For researchers, it helps avoid duplication of efforts and shows opportunities for collaboration.” Production research is a core part of NPB’s mission to improve the economic condition of America's peanut farmers and their families. Over the last 20 years, the National Peanut Board has invested more than $37 million in production research. This total includes leverage of just $871,500 from NPB and other industry partners to receive matching funds from the National Institute of Food and Agriculture (NIFA), which has yielded over $2.5 million for peanut production research. NPB supports research primarily through proposals from peanut-producing states' certified peanut producer organization. From improving disease resistance and drought tolerance to developing high oleic varieties and mapping the peanut genome, NPB-funded research is making peanut farmers more sustainable and more profitable. NPB’s online home for production research stories and news is PeanutResearch.org. t BYLAURENHIGHFILL WILLIAMS NATIONAL PEANUTBOARD

Sunbelt Ag Expo Field Day set for July 23

The 2020 Sunbelt Ag Expo Field Day is scheduled for July 23, 2020. Farmers are invited to attend in order to learn practical information from the region’s top agricultural scientists about the newest technologies farmers can use to improve their operations.

While Field Day will have a different feel this year, the Sunbelt team looks forward to welcoming farmers and professionals in the ag industry to a Driving Tour of the Darrell Williams Research Farm. Visitors will enjoy Field Day from the comfort of their own vehicle as they learn from university researchers and vendors.

The half-day event will take place at the 600-acre Darrell Williams Research Farm, located at the Expo show site at Spence Field in Moultrie, Georgia. Visitors at Sunbelt Ag Expo Field Day on July 23 will be able to see crop demonstrations and examine research trials by the University of Georgia Peanut Team and company vendors. Registration is free for anyone who works farmers can choose to pull aside at stops we will present the research being in agriculture. that particularly spark their interest to conducted in a different format. We are

Visitors should arrive thru Gate 2 further investigate plots and visit one-onencouraged that those individuals and anytime between 8:00 a.m. and 9:00 a.m. one with the researchers. companies conducting that research are to begin the tour. Directional signs will “We have the unique ability to work working with us to overcome the direct those in attendance to a red tent with university and corporate researchers challenges that have been presented.” where they will register, receive a on our Darrell Williams Research Farm, For those unable to attend Field Day, welcome bag including snacks, register where we continue to conduct cotton, videos from the event will be available for CCA credits and begin the tour. peanut, corn, soybean and forage research online at sunbeltagexpo.com.

Attendees will never have to step out — all aimed at improving the farmer’s The Sunbelt Ag Expo is located of their vehicle for this process. Once bottom line. We look at the latest seed southeast of Moultrie, Georgia, on registered, visitors will then drive-thru the varieties, crop protection methods, soil Georgia Highway 133. For additional tour path while viewing pre-recorded fertility, irrigation and precision ag information on the field day, visit segments featuring university researchers technology,” says Chip Blalock, Sunbelt sunbeltexpo.com or call 229-985-1968. t and company vendors. In addition, Ag Expo executive director. “This year,

2020 Georgia Peanut Tour Canceled

For the first time in the “We hope you are all well in spite of history of the Georgia the challenges we all are facing. It has Peanut Tour, the annual been a difficult year in many regards. This event which brings includes trying to plan a tour for a large hundreds of international and guests from group of people to travel together, eat multiple states, has been canceled. The together, visit numerous facilities, etc., all tour is held annually in September and while maintaining strict social distancing has been a way to provide the latest and safety precautions. information on peanuts at harvest. The “We love hosting the Georgia Peanut annual tour also provides a first-hand Tour, and were determined to try and view of industry infrastructure from make it happen. However, as planning production and handling to processing progressed, it became apparent that the and utilization. prudent option would be to cancel the

In a letter addressed to former and 2020 Georgia Peanut Tour. This was not prospective tour attendees, Tim an easy decision, but I am confident it Brenneman, 2020 tour chariman, said the was the right decision. following. “At this point we will table our plans

to go to Southwest Georgia, and hopefully will be there in September of 2021. In the meantime, we will work hard to still produce a great crop of high-quality Georgia peanuts, and we look forward to you joining us next year!”

The Georgia Peanut Commission, University of Georgia-Tifton Campus and Griffin Campus, and the USDA Agricultural Research Service National Peanut Research Lab coordinate the tour.

Visit georgiapeanuttour.com to take a stroll down memory lane of past tours. t