10 minute read

Exhibitors Share Latest Tools, Software, & Services- Product Focus, Summer 2025

The energy on the Trade Show floor at SEAA’s 2025 Convention & Trade Show in Pittsburgh was nothing short of electric. Attendees explored the latest tools, technology, and services from 60 exhibitors. From equipment demos and product launches to hands-on training solutions, the Trade Show offered something for everyone. The following exhibitors showcased these new products. See a list of all exhibitors on page 14.

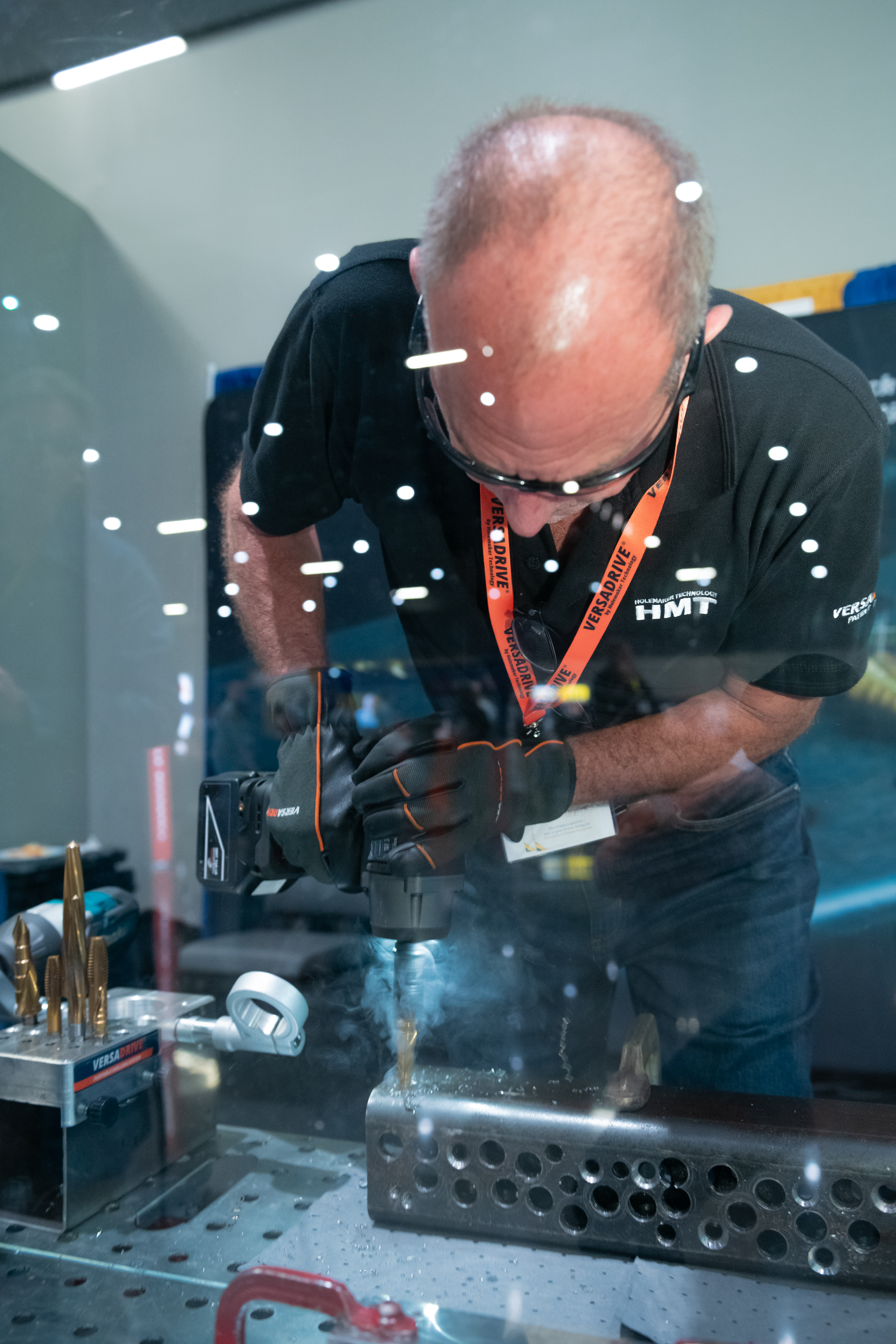

■ Holemaker Technology Modular Drilling

Holemaker Technology (HMT) is revolutionizing the metalworking industry by delivering faster, safer, and more efficient cutting and drilling solutions. Inspired by the lack of innovation in portable drilling, HMT was founded to address real-world job site challenges. The company’s success stems from listening to field workers and designing tools that directly solve their problems.

Notable innovations include the patented VersaDrive® MAX Reamers, the world’s first modular drilling solution for

impact wrenches. The heavy-duty 13/16” shank and specially designed cutting geometry allows for superior performance and portability on site. Ideal for steel erection and bridge work, it can be used in thicker materials with higher torque applications. VersaDrive® MAX Reamers are safer and more effective than standard hex nut reamers as they are directly attached to the impact, eliminating the risk of tool drop and improving control of the tool.

■ Raken Incident Data Apps

With Raken’s incident capture tools, contractors can accurately record incidents from the field or office, then use the easy submit button to electronically report yearly work-related injury and illness data directly to OSHA.

Web and mobile apps help customers document details of incidents and add supporting documents, like photos and witness statements. They can also automatically notify stakeholders for real-time visibility.

Because Raken integrates directly with OSHA’s Injury Tracking Application (ITA) via

API, there’s no need to duplicate data. Instead of downloading separate forms or working across multiple systems, users simply connect their ITA accounts with Raken to meet obligations to OSHA.

All incident data is automatically organized in the correct format. Simply verify and submit to stay compliant with zero hassle. Users can download comprehensive incident reports to identify recurring issues and make proactive improvements to their safety plans.

■ Torque with GWY

Revolutionize your approach to torque with Enerpac’s BTW1000B battery torque wrench. With a torque capacity of up to 1000 ft-lb. and pinpoint accuracy, this wrench is designed for professionals who demand performance. Its advanced brushless motor runs cooler and maximizes efficiency, keeping you productive throughout the day.

The intuitive LED display allows for quick torque setting adjustments in a matter of seconds. Supplied with two quick-charging batteries, there's always one ready for action, minimizing downtime

significantly. Lightweight and portable design facilitates solo operation with ease, allowing you to navigate around the jobsite without tangles or tripping hazards from cords or hoses.

Plus, the robust 1” square drive ensures durability against wear and tear from high levels of torque while fitting standard impact sockets. From bridge constructions to intricate commercial projects needing finesse in hard-to-reach areas, the BTW1000B stands as your reliable companion offering unmatched mobility and performance on every project. Whether you prefer to purchase or rent, reach out to GWY for a complimentary quote.

■ TurnaSure from Wrought Washer Manufacturing

Wrought Washer Manufacturing Inc., the largest washer manufacturer in North America, has added TurnaSure and its innovative ViewTite Direct Tension Indicating (DTI) Washer line. Direct Tension Indicators (DTIs) arrived during the shift from hot-riveted steel structures with the introduction of High Strength Bolts to ASTM A325 and A490. Direct Tension Indicators ensured precise and consistent clamping forces. In 1985, DTIs were standardized to ASTM F959.

TurnaSure refined the designs of DTIs ensuring unparalleled accuracy and developed ViewTite to meet ASTM F959, with a visible durable green elastomer placed in formed tubes on the washer’s top surface with a two-step compression process. This eliminates inconsistencies when putting elastomers in pockets under DTIs where

variations in steel surface conditions, coatings, and larger clearance holes affect accuracy and reliability.

ViewTite eliminates additional washers underneath when used on oversized or expanded clearance holes and thus longer bolts. The elastomer glows under a black

light for safe inspection in low-light environments. ViewTite has proven itself in major infrastructure projects, including the Verrazano and George Washington Bridges in New York. Recognized for its breakthrough innovation, ViewTite received the Fastener Innovation Award in 2022.

■ Magni Rotating Telehandler

For steel erectors who need precision, power, and flexibility on complex jobs, the Magni RTH 6.31 rotating telehandler delivers unmatched performance. With a maximum lifting height of 101 feet, an 88-foot reach, and a lift capacity of 13,200 lbs., it’s built to handle structural steel with confidence, even at height.

The RTH 6.31 excels in steel erection environments where safety and accuracy are non-negotiable. Its Load Moment Indicator (LMI) system, combined with RFID-tagged attachments, automatically adjusts load charts to keep crews working within safe limits. Magni’s Load-Limiting Technology prevents overloading and ensures stable lifts, even on challenging terrain.

Outfitted with Magni’s patented outrigger system and automatic leveling via digital display, the RTH 6.31 sets up fast and stays secure—critical when positioning beams, trusses, or columns in tight or uneven spaces. Plus, its 3-in-1 design functions as a telehandler, rough terrain crane, and aerial work platform, minimizing the need for multiple machines on site. Inside the cab, operators benefit from HVAC, air filtration, and an intuitive touchscreen for total control. For safer, more productive steel erection, the RTH 6.31 is the lift your crew can rely on.

■ Jekko Hydraulic Manipulator

Need to install steel in a complex space but didn’t have the right tool to do so? Jekko not only innovated a new operating system but has taken the market by storm with the new JIB00GR. This powerful hydraulic manipulator with interchangeable heads can seamlessly handle steel beams and large pipes. Users now have the ability to manipulate 360 degrees continuous rotation and 183 degrees of vertical articulation.

With the Jekko Plug & Play system, simply connect the crane’s electrical and hydraulic system and it will fully integrate and operate via the crane’s remote control. Designed for safety, precision, and complete control, you can access places that once felt impossible. With this accessory, productivity is drastically increased. A single operator can unload, move, and install a beam or pipe weighing up to 1100 lbs. Jekko is available from FASCAN International.

■ FallTech SRL with On-site Repair

FallTech introduces the FT-R+, the industry’s first Class 2 leading-edge self-retracting lifeline (SRL) with on-site repair capability. Featuring the innovative SpeedLine™ system, the FT-R+ allows damaged lifelines to be safely replaced in minutes—eliminating costly off-site repairs and reducing downtime.

At the heart of SpeedLine is LineLoc™, a simple locking mechanism that disengages a damaged cable and secures a replacement quickly. This field-ready solution brings unmatched convenience and enhanced safety to job sites, addressing a critical challenge in fall protection: SRL maintenance delays. Built on the proven FT-R™ platform, the FT-R+ supports workers up to 420 pounds and offers versatile anchorage options—above, at, or up to 5 feet below the D-ring. Its compact design, advanced energy absorption, and smooth cable movement make it ideal for demanding leading-edge applications.

■ A1A Product Suite Apps

A1A Software LLC has released the latest version of its A1A Product Suite, enabling seamless integration between individual apps and 3D Lift Plan—without the need to import Sketch Pad or Jobsite Designer plans. The suite reflects A1A’s move to app-based tools that unlock new features and insulate users from browser-related disruptions.

3D Lift Plan remains the foundation of the suite, known for its use in bids, critical lift planning, rigging documentation, and simulations. Now enhanced by stand-alone apps, SketchPad, Rigging Designer, Jobsite Designer, and 3D Lift Vision, users can access the level of planning appropriate for their roles. For example, SketchPad lets users sketch

jobsites on a scaled Google Map image, while Rigging Designer enables dragand-drop creation of complex rigging plans. Jobsite Designer allows intuitive editing of site objects, and 3D Lift Vision immerses users in virtual simulations based on actual lift plans.

The full suite is available for download from Microsoft, Google Play, and Apple App Store platforms.

■ Sales Synergy Group Hearing Protection

Over the past five years, noise-induced hearing loss claims have surged by 300%, putting companies at risk financially and operationally. In construction, one of the top five physical injuries is hazardous noise levels. Yet, many employees resist wearing hearing protection because it often eliminates Auditory Situational Awareness (ASA), a critical component of staying safe on the job. In fact, three of the top five construction injuries are directly tied to loss of ASA.

To address this, the Clear 360 Pro offers a breakthrough solution. Its next-generation hearing protection keeps workers aware and safe. Clear 360 Pro allows your team to maintain 100% ASA, combining elite hearing protection with unmatched environmental awareness—so workers never have to choose between safety and performance.

Key features include five listening modes, full-directional sound detection, hyper-realistic awareness, certified 24dB NRR protection, all-day comfort and endurance, IP64-rated durability, and tax-deductible qualification.

Whether handling machinery, working at height, or navigating noisy environments, Clear 360 Pro ensures your crew hears what matters, when it matters most. Hearing protection should be as standard as steel-toed boots and harnesses. Choose Clear 360 Prowhere protection meets performance.

■ Safety Plus Safety Management Software

Safety Plus announces the general availability of its new flagship software for safety management, Safety Plus Edge. This software program is designed to help steel erectors, commercial construction companies, and other businesses operating in high-risk industries streamline safety processes, ensure regulatory compliance, and protect their workforce.

Safety Plus designed Edge to be both innovative and intuitive to use, helping customers simplify daily tasks and safety program tracking. Critical features include a learning management system, automated requirements tracking, audits and inspections, incident management, safety meeting administration, and reporting and analytics.

Recognizing that not all companies have full-time safety managers (or need expert support to develop and scale their safety programs as their companies grow), Safety Plus also offers Edge to customers through a program management process known as Safety Plus Edge Pro. In this program, customers will benefit from customized program development by its team of safety managers, who assess, implement, and support customer safety programs while using Edge as the critical tool for administering and measuring success of the program.

With Edge and Edge Pro together, Safety Plus can help customers keep their workers safe, wherever they are on their program journey.

■ JLG Electric Boom Lift

JLG Industries, Inc., announces the EC600AJ, a new 60 ft. electric articulating boom lift for North America. Designed for performance and sustainability, the EC600AJ offers 550 lbs. unre stricted and 750 lbs. restricted platform capacities, with a 60 ft. platform height and 36-ft horizontal outreach.

Its articulating design enables 27 ft. 1 in. up-and-over reach, a 130-degree jib articulation, and 400-degree swing for precise positioning around obstacles, making it ideal for construction, facility maintenance, and renovation. Powered by dual 10.7kWh lithium-ion batteries and equipped with 4WD AC drive motors, the EC600AJ handles rough terrain with 40 percent gradeability and optional 4WS for tight turns.

Additional features include foam-filled rough terrain tires, a compact design for efficient transport (two units per trailer), and a rugged hybrid hood with internal power track for easier servicing. •