2 minute read

The Bargmann L.E.N.S.

Site Specific: The element that Bargmann highlights in MASS MoCA’s site are the imperfections. With almost 300 years of industrial use, the wear and tear in the bricks and pavings tell a story. In order to enhance that story, Bargmann simply created connections between plazas and cleansed the site of hazardous material to allow the public to appreciate the structure’s hard work.

Material Magic: Most of the material work rearranged the elements to open up the pathways for access and create the blank spaces for flexible programming. All the materials feel like they had been there before but were simply uncovered to reveal themselves.

Advertisement

Catalyze Regeneration: MASS MoCA has grown exponentially in the last 20 years. Today it stands as one of the most prominent contemporary art centers in the U.S.

This site seems to be a rare case of industrialization. Since the beginning, the site has retained productivity instead of sitting vacant for many years like most post-industrial sites. It would be interesting to know if this impacted the ability to maintain materials and be able to experience a lot of the history since the site had only just been abandoned. If people were able to anticipate the industrial site’s collapse, would it make the design process easier and more efficient since the pieces are still in working order? Or is it more interesting when the site sits for years as nature takes back over?

Case Study 3: From Ford to Forward

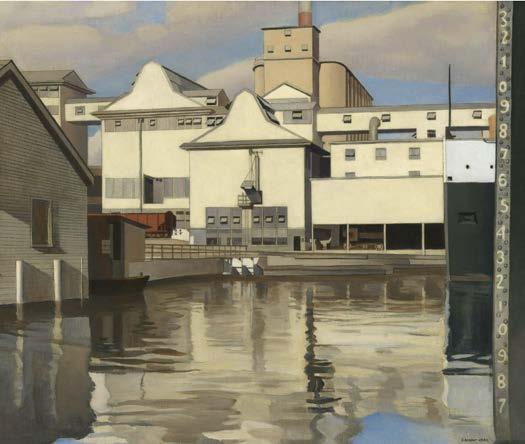

Ford River Rouge

Dearborn, Michigan

1999 - 2001

The beginnings of the Ford River Rouge plant started in 1915 when Henry Ford bought a 2,000-acre stretch along the river. Initially, he did not have a plan for the land and even imagined it to become a bird sanctuary at one point.

(The Henry Ford, 2022) When World War I began, Ford was hired to build boats for the U.S. Navy and began constructing the complex.

In the 1990s, William Clay Ford Jr had a vision for a more ecological campus for the monstrous campus in Dearborn. Ford believed he could transform the industrial icon into a model for sustainability as the world headed into the 21st century. Instead of building from scratch, the intent was to revitalize the existing plant with new ecological systems. William McDonough led the master planning team to retrofit this transformation.

The design centered around developing the world’s largest green roof totaling 600,000 square feet. The green roof overshadowed the other efforts that Bargmann had led for the project. These elements included swales and retention ponds to regulate the water cycle, phytoremediation to extract chemicals from the water that goes into the Rouge River, porous paving to allow for water to reach the soil underneath, and more.

The Bargmann L.E.N.S.

Site Specific: The inspiration for the ecological system came from the industrial system. The new biological infrastructure complements the Ford plant - “manufacturing vehicles along with clean water, air and soil.” (D.I.R.T.. 2021) On D.I.R.T.’s website, Bargmann has drawings of the industrial systems alongside the ecological ones showing the influence and similarity

Material Magic: Instead of tearing everything down and starting from scratch, the design used the existing campus to create ambitious ecological systems. The National Trust for Historic Preservation protected many of the buildings because Albert Kahn designed them. Some of the structures were even considered artifacts because of their obsolete processes, such as the coke ovens.

Catalyze Regeneration: There is a clear concept about the campus’s past, present, and future. The team uses the past to inspire the present, to create the future. They used Ford’s philanthropic spirit to pilot many ecological systems that are now regarded as requirements in landscape projects - stormwater management, green roofs, etc. These systems proved to clean the water, provide habitats, and save the campus money because of natural energysaving capabilities such as the green roof cooling the building in the summer and retaining heat in the winter.