1 minute read

Logwood Dye

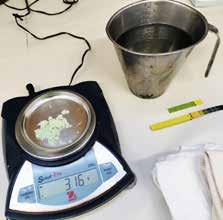

As my research took me to discovering the significance of logwood dyeing I decided to try the historical dyestuff myself. I bought logwood chips online and soaked them in a pan of water for 2 days. I made a 40% and a 20% WOF dye so I could find out what colours can be created based on strength of dye. After two days the logwood chips turned from their natural orange-brown colour to a deep, dark purple and the water was vivid purple so I could tell this was going to be a potent dye. I used cotton and bamboo fibres mordanted with either alum, iron, titanium oxalate or soya milk and nettle as a binder. Logwood is PH sensitive so I experimented with adding lemon juice and soda ash to the 40% WOF exhaust dye bath. Unfortunately the dye bath was too exhausted and when the swatches dried they didn’t keep the golden yellow tones that I saw in the dyepot but faded to a light brown shade. The 20% swatches left in the dye bath overnight also lost richness of colour. I concluded that for best results the dyestuff needs to be at least 40% WOF and for lighter tones, fabrics should be left in the dye bath for a short period of time.

Advertisement

Scour fibres

Mordant Heat dyestuff

Strain out dyestuff

Add fibres

Rinse

Use soda ash or PH neutral soap

Slowly simmer Do not boil

Pre-soak fibres and frequently stir dye bath

Examples:

Alum

Iron

Tannin

Soya milk (as binder)

Copper

Tin

Titanium Oxalate

Rhubarb leaves

Use a sieve or muslin cloth

Thoroughly in warm PH neutral water