11 minute read

FACTORS AFFECTING WOOD MECHANICAL PROPERTIES Wood Density Moisture Content Specific Gravity Hardness Strength Groups Brittleheart Rates of Growth Percentage of Latewood Position in Tree Natural Durability Temperature Effect of Knots Overgrowth of Injury Grain Distortion Compression Failures Blue Stain Pinhole Borer Damage Lyctid Damage Marine Borers Termite Damage Decay – Fungi - White, Brown, Soft Rot Gum Veins

FACTORS AFFECTING WOOD MECHANICAL PROPERTIES

The main factors affecting the mechanical properties of wood (significant in building construction) include density, brittleheart, rate of growth, percentage of latewood, position in tree, moisture content, temperature, duration of loading, effect of knots, grain distortions, blue stain, pin hole borer damage, decay, gum veins, shakes, splits, and checks.

Advertisement

Wood Density

Wood density is defined as the weight of wood in kilograms which would occupy a volume of one cubic metre at a given moisture content. The density of seasoned wood (air dry density) is given at the average figure of 12 % moisture content. Age, diameter, height, radial (trunk) growth, geographical location, site and growing conditions, silvicultural treatment, and seed source all to some degree influence wood density. The density of a wood correlates with its strength (mechanical properties). For example, mahogany is a medium-dense hardwood that is excellent for fine furniture crafting, whereas balsa is light, making it useful for model building. One of the densest woods is black ironwood. In general, the denser a species, the greater the mechanical properties of its clear material.

Moisture Content

Water occurs in living wood in three locations, cell walls, in the protoplasmic contents of the cells, as free water in the cell cavities and spaces, especially of the xylem. In heartwood it occurs only in the first and last forms. Wood that is thoroughly air-dried retains 8–16% of the water in the cell walls, and none, or practically none, in the other forms. Even oven-dried wood retains a small percentage of moisture, but for all except chemical purposes, may be considered absolutely dry. The general effect of the water content upon the wood substance is to render it softer and more pliable. Drying produces a decided increase in the strength of wood, particularly in small specimens.

11

Specific Gravity

The single most revealing property of wood as an indicator of wood quality is specific gravity as both pulp yield and lumber strength are determined by it.

11 Source Qld Forestry ForEd Project 1982-1985

Specific gravity is the ratio of the mass of a substance to the mass of an equal volume of water. Upon drying, wood shrinks and its density increases. Variation of specific gravity within the bole of a tree can occur in either the horizontal or vertical direction.

Hardness

The Janka hardness test was created by Austrian-born American researcher Gabriel Janka (1864–1932). It measures the resistance of a sample of wood to denting and wear. A common use of Janka hardness ratings is to determine whether a species is suitable for use as flooring.

Strength Groups

PNG woods have been classified according to the Australian System of Strength Groups (devised and reviewed by CSIRO and State Forest Services).

Property S1 S2 S3 S4 S5 S6 S7

Basic density Kg/cubic m3

Modulus of rupture megapascals 900 760 640 540 450 375 320

103 86 73 62 52 43 36

Module of elasticity megapascals

Maximum crushing strength megapascals 16300 14200 12400 10700 9100 7900 6900

52 43 36 31 26 22 18

Maximum shear strength Megapascals 13.1 11.0 9.1 7.7 6.6 5.5 4.6

Modulus of rupture is the measure of the maximum compressive or tensile strengths in the wood fibres at the point of fracture. It is a direct measurement of the strength of wood in bending. Module of elasticity is a measure of the stiffness or rigidity of wood. E.g., for a beam, the modulus of elasticity is a measure of its resistance to deflection. Compression parallel to grain (maximum crushing strength) is a measure of the maximum stress sustained by wood under a load applied slowly parallel to the grain. It indicates the relative suitability of timber for columns. Shear is a measure of the ability of wood to resist slipping of one part upon another alongside grain. Creep is long term deformation under load. A wood member loaded continuously for ten years could only carry about sixty percent of what it can easily sustain for a few minutes. Timber being of a non-crystalline nature is less subject to fatigue failure than metals but it is not immune.

Brittleheart (Heart in hardwoods, Pith in softwoods)

12 The pith in softwoods (heart in hardwoods) forms at the centre of the tree. This wood may be a lot weaker and lower in density than surrounding wood fibre. Wood near the centre of the tree may have suffered high compressive stress in the initial stages of growth and may be abnormally low in impact or shock resistance and liable to abrupt failure at comparatively small deflections. Grading rules address the occurrence of brittleheart and reject its use.

Rates of Growth

Wood from trees of moderate growth is likely to have some superiority over very fast or very slow grown material.

Percentage of Latewood

Some species of pronounced seasonal growth habits have thicker walled cells in the wood formed late in the growing season and such wood is denser and stronger than that formed at the beginning of the season.

Position in the tree.

Acacia tray depicting early wood (light colour) and late wood (darker colour) across the stem. Photo credit Dick McCarthy.

Wood from the butt section of a tree is expected to be more dense and stronger than wood from the top of the tree.

12 Source Qld Forestry ForEd Project 1982-1985

Natural Durability

The wood of timber species is classified according to a durability classification based on the resistance of sound untreated heartwood (of hardwoods) to attack by wood destroying fungi, borers, and insects. The sapwood of all species is regarded as non-durable. CSIRO Forest Products Durability Classification

Class 1 Very durable Suitable for long `term use in structures exposed to the weather, and in contact with the ground.

Class 2 Durable Suitable for use in the ground and for unprotected exterior use under normal conditions. Class 3 Moderately durable Suitable for protected exterior work and for interior use. Not suitable for use in contact with ground.

Class 4 Non-durable Not suitable for exterior use unless treated with preservative.

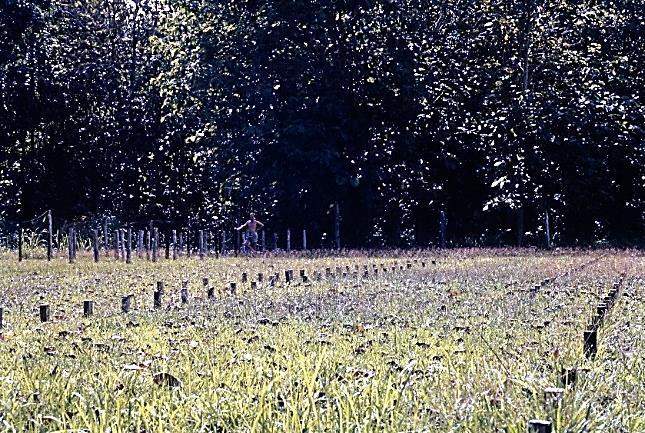

“Graveyard” timber durability trials CSIRO/TPNG Forests Kerevat ENB PNG 1967 & Bob Willis TA. Photo credit Ian Whyte.

Temperature

Above normal temperatures tend to lower the strength properties of wood and lower temperatures make it stronger.

Effect of Knots13

Knots can have a major effect on mechanical properties since they interrupt the continuity and change the direction of the wood tissue. Knots are formed by longitudinal sawing of tree trunks through areas where branches were attached to the trunk. The slope in grain around knots can be very severe and thus reduce the strength properties of the piece of wood.

Overgrowths of Injury14

Formed in the living tree when branches fall off or the tree is damaged by fire, insects, or animals. New woody tissue grows into the damaged area. Similarly, to knot effect, the grain at overgrowth is discontinuous, and thus reducing the strength of the piece of wood.

13 Source Qld Forestry ForEd Project 1982-1985 14 Source Qld Forestry ForEd Project 1982-1985

Grain Distortion15

Besides grain distortion caused by knots, there are other types of grain distortion as spiral grain, diagonal grain, interlocked grain, and curly grain.

Sloping grain may be due to spiralling in the trunk of the tree although it can also be caused by not sawing parallel to the log longitudinal axis.

Compression Failures16

Localized creases in the wood arising from severe stresses due to high winds, or the felling operation, can cause a serious reduction of tensile strength and impact resistance, leading to a brittle fracture.

15 Source Qld Forestry ForEd Project 1982-1985 16 Source Qld Forestry ForEd Project 1982-1985

Blue Stain17

The sapwood of many species is very susceptible to discoloration by blue stain fungi in warm humid weather. Unless a very severe attack, little impact on mechanical properties.

Pin Hole Borer Damage18

The ambrosia or pin hole borer can cause a serious weakening in strength if there is a large concentration of holes.

17 Source Qld Forestry ForEd Project 1982-1985 18 Source Qld Forestry ForEd Project 1982-1985

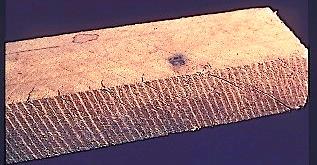

The characteristic effects of ambrosia beetle damage on wood is depicted by the tunnels and associated staining. The effect of damage is largely on appearance, sawn recovery and in severe cases on strength. Lyctid damage to susceptible timber19

The recognition signs of lyctid powder-post beetle attack. Unchecked attach can result in a hollowing out of the wood with resulting loss of strength.

19 Source Qld Forestry ForEd Project 1982-1985

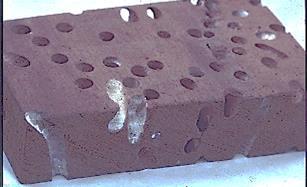

Marine Borers20

Marine borers cause extensive damage to wood which has been underwater for any length of time. A wood boring mollusc (teredo – shipworm) causes these large holes. Termite damage21

Subterranean termites bridging of ant caps. The bridging of ant caps by termites makes recognition of attack easy. The strength of damaged timber is greatly reduced.

20 Source Qld Forestry ForEd Project 1982-1985 21 Source Qld Forestry ForEd Project 1982-1985

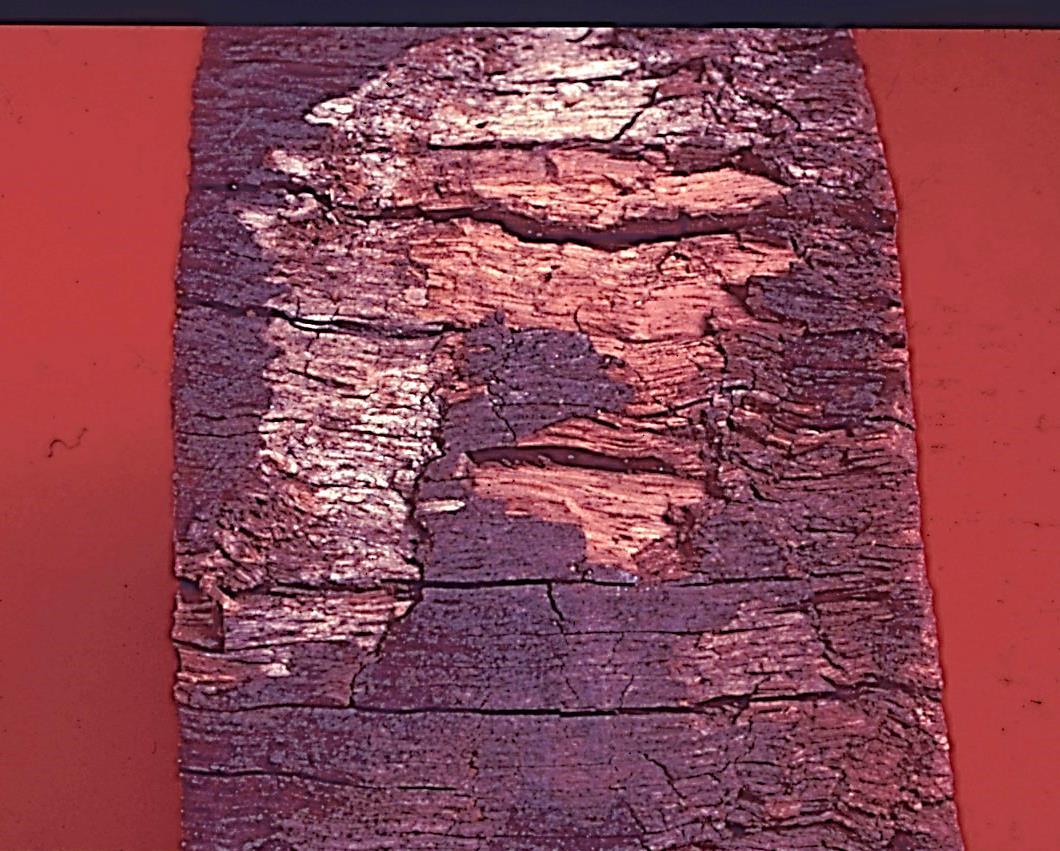

Drywood termite damage by West Indian drywood termites is evidenced by the presence of frass. Wood strength is greatly reduced by the tunnel effect as shown.

Pine beam attacked by West Indian drywood termite22

22 Source Qld Forestry ForEd Project 1982-1985

Decay

Wood, in which decay fungi have become well established has little strength, particularly regarding impact resistance.

Fungi as agents of damage23 . Here fruiting bodies of a fungus on a piece of rotting wood.

White Rot24 . White rot fungo require moist wood and attack is mostly on the inside. This fungi feeds on the brownish lignin leaving the white cellulose. White rot seriously affects wood strength.

23 Source Qld Forestry ForEd Project 1982-1985 24 Source Qld Forestry ForEd Project 1982-1985

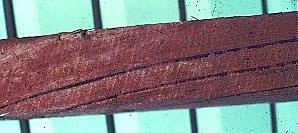

Brown rot25 . For attack by brown rot, wood must be wet at least intermittently. The fungus feeds on the cellulose leaving the lignin, hence the brownish colour. Affected wood eventually breaks up into cubical pieces which crumble to brown powder. Brown rot seriously affects the strength of wood. It may be difficult to detect because it occurs inside the wood.

Soft rot.

26 Soft rot tolerates much greater moisture conditions and are found in damp locations. The wood is degraded inwards form the surface. Affected wood is usually soft but becomes hard and brittle when dried. The fungi feed mostly on cellulose and hence the wood becomes darker in colour. The strength of wood is seriously affected.

25 Source Qld Forestry ForEd Project 1982-1985 26 Source Qld Forestry ForEd Project 1982-1985

Gum Veins27

Because of the discontinuity of tissue which they represent, gum veins reduce strength. Gum veins most frequent in eucalypts, the formation of which is a natural protective response to injury such as fire.

Shakes, Splits and Checks28

These forms of fibre separation reduce resistance to share stress. They should not be present in quantity at joints.

Cross shakes are usually formed when the wind forces on a standing tree are such that they cause a compression failure in the wood fibres or alternatively when the tree is felled and lands awkwardly.

27 Source Qld Forestry ForEd Project 1982-1985 28 Source Qld Forestry ForEd Project 1982-1985

Checks are usually formed when timber dries out and growth stresses that were in the tree are relieved in the sawn timber. Checks do not usually affect strength but can be unacceptable in flooring because of appearance. A forthcoming PNGAF Mag addresses the PNG wood scientists who studied the physical, chemical, and biological properties of wood to find ways of processing the raw material into different products such as pulp, paper, construction timber and into products such as chipboard, fibre board and laminated beams. They describe and categorise different wood species by chemical and physical attributes as durability, treatability, density, moisture movement, workability, availability, typical uses, and production methods. Wood is a renewable but expensive commodity. Wood scientists find ways to use every scrap of the raw material.

E.g., Chipboard was invented when people noticed piles of sawdust going to waste at sawmills. Wood Scientists ‘invented’ a new type of wood by mixing the sawdust with modern wood glues, making sure nothing went to waste. E.g., Paper is a vital part of the modern world. Wood Scientists use their skills and training to find new ways and processes to produce paper-based products. E.g., They also work in other fields such as primary processing (timber treating), plywood manufacture, fibre and particle board manufacture and saw-milling, secondary processing (furniture, joinery, building and timber construction) and other (research, marketing, labour, and training).