4 minute read

The Use of Forested Lands to Provide Major Forest Products

The Use of Forested Lands to Provide Major Forest Products.

The so-called major forest products are those directly derived from wood.

Advertisement

• Round logs for pole production for structures and bridges. • Round logs to be processed to produce sawn timber for buildings, furniture etc. • Round logs for processing to produce veneer for construction and furniture manufacture. • Round logs for wood chip production to make pulp and paper manufacture or conversion to other processed board products as particle board. • Round logs for firewood and/or charcoal production.

In most areas of the World where rainforest is under some form of management, sawlog and veneer log production have been the forester’s primary aim.

Tropical rainforest timbers show a very great range in qualities and characteristic, as would be expected from stands with such diverse botanical composition. Wood densities vary greatly e.g. a very heavy wood as kwila to a light wood as balsa. Similarly, colours range from black (e.g. ebony) through shades of red, brown, yellow, pink, purple to white. Varying degrees of durability, figure, strength, toughness and other working qualities can be found amongst rainforest species. With such variety present, species suitable for almost any timber use can be obtained from the rainforest, though the quantity of preferred species may be very small and often not worth extraction.

The World’s major timber using industries developed in the conifer (softwood) regions of the Northern Hemisphere whereas in the tropical regions, the use of timber for purposes other than fuel was generally very late in developing. Hence, the utilisation of rainforest species has for centuries been concentrated upon the export of relatively few species with outstanding characteristics not found amongst temperate species. This includes species such as ebony, mahogany, cedars etc. These species have been primarily specialty cabinet woods.

It is only in the last few decades that more general purpose species have been utilised on any scale from the tropical rainforests. This recent development has been sparked by a world wide shortage of such timbers, enabling tropical exports to compete with more traditional species on the World’s markets. At the same time, there has been a growing demand within the tropical rainforest countries themselves as living standards rise and as timber treatments ensure increased durability for the lighter and softer species.

Globally in 2002, of the 3.4 billion cubic metres of wood produced:

• Wood fuel was 53 % of total usage. • Sawn wood was 23 % of total usage. • Wood based panels as plywood, and other composite boards as particle board were 7 % of total usage. • Pulp and paper products were 12 % of total usage.

9

• Other industrial uses as charcoal production etc. were 4 % of total usage.

In PNG in 2002, of it’s annual wood flow of 8 million m3:

• 63% was wood fuel (5 million m3 firewood)5 . • 23 % was log exports (1.8 million m3). • 8 % was industrial processed exports as sawn timber, plywood, veneer and wood chips (0.645 milion m3). • 2 % was domestic industrial wood usage as sawn timber, plywood (0.2 millin on m3).

Destinations for PNG log exports in 2002 were:

• A total of 1.8 million m3 of logs were exported. 90 % of the log trade was to China,

Japan and Korea. • Other minor markets for PNG logs included Vietnam, Taiwan, India, Hong Kong and the Philippines.

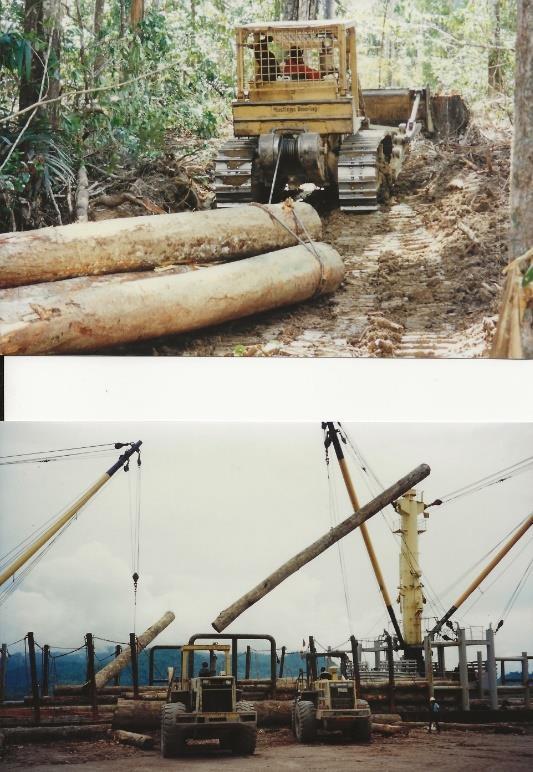

Log export Vanimo TA. Log Pond, Bay of Tokyo Japan.

Photo Credit Dick McCarthy 1995. Photo Credit Dick McCarthy 2003.

Destinations for PNG wood processed products in 2002 were:

• Some 80,000 m3 of sawn wood with Australia being the major market. Other minor markets included countries as New Zealand, China, and Korea.

5 FAO studies published CFA Newsletter Vol 4 December 2002. 10

• Sawn wood species included Balsa, Kwila, Dillenia, Hopea, Malas, Mersawa, Pencil

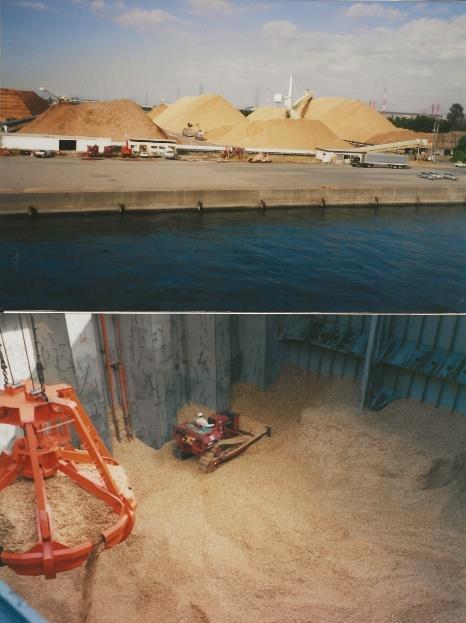

Cedar, Red Cedar, Taun, Vitex, Walnut, Water Gum, Wau Beech and mixed sawn batches. • Some 3,760 m3 of plywood was exported with Australia being the major market. • Some 97,000 m3 of wood chips exported with Japan being the major market. • Some 70,000 m3 of veneer exported with Taiwan and the Philippines being the major markets.

6 7 8

9

10 11 12

6 Sawn Kwila ready for export to Australia. Photo credit Dick McCarthy. 7 Sawn Rosewood Port Moresby ready for export to Fiji. Photo credit Dick McCarthy. 8 Sawn Rubberwood Galley Reach Central Province ready for export. Photo credit Dick McCarthy. 9 Veneer RH Operations Western Province ready for export. Photo credit Dick McCarthy. 10 Sawn Balsa being kiln dried at old Kerevat sawmill site. Photo credit Dick McCarthy. 11 Range of Plywood sizes exported to Australia. Source PNGFP. 12 Wood chips ex Madang being unloaded Bay of Tokyo Port. Photo credit Dick McCarthy. 11