10 minute read

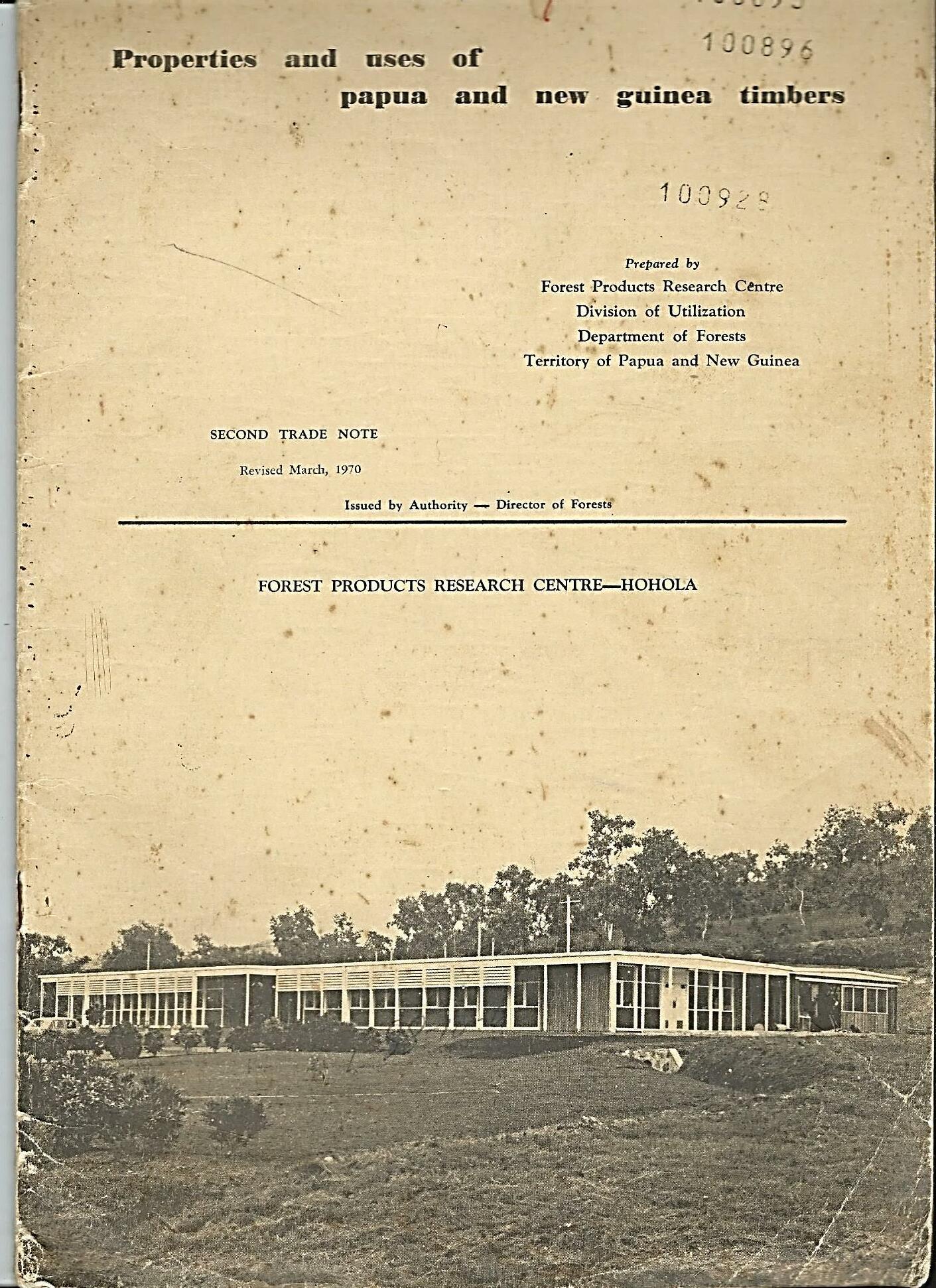

Forest Products Research Centre Hohola Port Moresby

from PNGAF MAGAZINE ISSUE # 9B-5B4H3 of 24th June 2022. Eminent TPNG Forester Des Harries.

by rbmccarthy

FOREST PRODUCTS RESEARCH CENTRE - A PERSONAL RECOLLECTION. By Des Harries.

Prior to Independence in 1975, the Forestry Department of the Territory of Papua and New Guinea was organized in the traditional manner of Australian Government Departments. In this case, under the Director, were the various Divisions with their Chiefs - thus Divisions of Silviculture; Management; Botany and Utilization.

Advertisement

John Colwell, after experience with CSIRO Division of Forest Products in Melbourne, was appointed as the first Chief, Division of Utilization, initially based at Konedobu, Port Moresby. The role of this Division was the oversight of local TPNG wood processing, and in this capacity, Colwell established a good rapport with the timber industry leadership. His contacts with CSIRO Forest Products were of great value, particularly regarding his achievement of getting the Forest Products Research Centre established on a site in the Port Moresby industrial area of Hohola.

While I was working out of the Forest Office in Rabaul, Colwell approached me in early 1965 with the proposal to join the new Centre - I declined, with the impression that my level of experience was insufficient. However, two years later, having been working in the Particle Board industry in Australia, I reconsidered my position and John obtained a position for me at Hohola.

During my absence in Australia Gerry Vickers had taken on the role of supporting John Colwell in establishing the Centre. The building itself was a show case of fine timber craftsmanship - an exhibit of the best of local timbers. Guidance in the fit-out of the laboratories had come from CSIRO, and the technical excellence of this brought great credit to both Colwell and Vickers.

Some excellent people were also recruited. Wood preservation research was led by Vickers with the technical support of Colin Levy, a chemist who had previously been with the Department of Agriculture at the Kerevat Research Station. Minor Forest Product research and development was the field of Mr. Jack Zieck, formerly a senior officer in Dutch controlled West New Guinea. Wood identification and the preparation of associated timber property publications was handled by Peter Eddowes. The supporting workshop was run by Les Austin, who for many years had run the Kerevat Sawmill workshop. Experimental sawmilling equipment was run by Arthur Mobbs, who likewise had spent many years in the Department’s sawmill at Kerevat. The extensive wood-working facility at Hohola was managed by a local officer and wood tradesman, Joel Nalong. Several apprentices became skilled tradesmen working under Joel during these years, 1960’s-70’s.

When I joined in June 1968, I was given the new task of monitoring the possible development of a woodchip export industry.

Subsequently Warwick Stokes was recruited and took on the task of developing kiln drying schedules. Canadian recruit, Col Stelmack, carried on this work when Stokes was transferred for a stint at the Bulolo Forestry College.

The main building of the Forest Products Research Centre became the office of the Chief of Division of Utilization as well as that of Forest Products research officers. In effect the role of the Division of Utilization within the Department of Forests had changed considerably. The majority of interaction between the Department and Industry had now devolved to the Central Office of the Department. This latter office also took up new quarters in a building at Hohola adjacent to the Forest Products Research Centre.

The Department during these years also saw the development of Forestry Research facilities at Bulolo somewhat in parallel to the Hohola facilities.

The construction of the main building mentioned above provided for the housing of a Forest Products themed library, a wood sample room featuring collections of timbers of all continents as well as New Guinea, a chemical laboratory and work spaces as well as office accommodation and reception/typing facilities, and a photographic darkroom. Another feature was the provision of two rooms with special air-conditioning which was a possible requirement for certain research projects. One of these subsequently became the special microscope room used extensively in the measurement of wood fibres, as part of the wood pulping studies done in cooperation with CSIRO in Melbourne, and the other for wood decay studies.

The offices were lined with beautifully prepared plywood featuring selected New Guinea timbers and peeled at the then Commonwealth New Guinea Timbers plywood mill in Bulolo. These plywood panels were beaded with narrow strips of New Guinea ebony. Work benches were features in themselves, being constructed of Klinkii pine.

It was not many years before extensions became necessary with the increasing workload. An extension to the chemistry laboratory was first. This was followed by two large storage areas, one of which was devoted to the extensive wood collection involved with the aforementioned wood pulping studies.

Located on the Hohola site was a caretaker’s cottage, which subsequently was taken over for housing expatriate staff.

This large landholding off Frangipani Street, Hohola also housed special research facilities including pressure treatment plant, wood kiln, woodchipper and wood chip storage/treatment facility, sawmill, including a twin edge circular saw bench and saw sharpening facility, mechanical workshop, cabinet making workshop, inflamables storage shed and an accommodation block for local officers.

23 The construction of the inflamables storage shed is of special interest. It was the last building to be put up at the Hohola site and was concurrent with the planning for the new House of Assembly near the University at Waigani. We decided to demonstrate the use of pressure treated timber shingles for the roof of this building, using plantation-grown Eucalyptus deglupta (Kamarere) from the Brown River.

Amazingly, for it was quite a small building, and about 200 metres from the main road, this roof was spotted by architects passing by on their way to the House of Assembly site. They came inquiring about the nature of this roof. The result was that they chose this material (treated kamarere shingles) for the roof of the ‘Haus Tambaran’ style House of Assembly building. It created a great deal of work manufacturing these shingles in the relatively small treatment plant at Hohola.

23 Powter A 1976 Papua New Guinea Shake and Shingle Manual Department of Forests 28

I was certainly fortunate to have been allotted the task of looking after the development of the woodchip export industry in New Guinea.

Pulping studies of New Guinea (Papua) woods had in fact been initiated decades earlier in the days of Jim McAdam. It arose out of the realisation that the proposed development of the ‘cutch industry’ - stripping the bark of mangrove trees in the Gulf of Papua for tannin production - would lead to massive volumes of otherwise wasted wood. CSIRO was coopted to evaluate the suitability of this wood for pulp production. Frank Phillips was recruited by the Forest Products Laboratory in Melbourne to do this work, and after an extensive lull, this New Guinea project was to be revitalised, but in a much more complex, yet promising way.

Japanese pulping interests had led the industry of exporting woodchips from southern Australian Eucalypt timbers, and they now looked to New Guinea as a further source of wood chips, all-be-it with different pulping properties, yet to be determined.

The Gogol Timber purchase area outside Madang was the first to be targeted, and so Madang and the Gogol became my fieldwork area. A Company called Japan New Guinea Timbers (JNT) was formed and three Japanese officers arrived in New Guinea to get things going. They were Messrs. Sato, Ito, and Takahashi. I got to know them very well, as we collected the first large scale sample of logs for trial pulp and paper making in Japan.

But the project did not stop there.

We next worked on collecting a massive sample from the Vanimo area during the resource assessment survey of that area. Ref Appendix 2 Pulp and Paper (Authors- Dick

McCarthy/Evan Shield/Mike Jones).

A statistically based sampling plan was developed by Mr. Bill Balodis of CSIRO in Melbourne, who became a regular visitor. We also carried out a study, based in Vanimo, of the behaviour of woodchips stored in piles. Dr. Harry Greaves, wood decay expert, also from CSIRO in Melbourne, was involved in this study, as was Col Levy from the Forest Products Research Centre at Hohola.

The scientific paper24 based on this work was presented by me at a Conference of the Australia New Zealand Pulp and Paper Industry Technical Association (APPITA) held in Hobart in March 1972. This was the first scientific paper sourced in the Forest Products Research Centre to be published.

24 Phillips F H and Harries E D 1975 The Pulping and Papermaking Potential of Tropical Hardwoods 1 CSIRO 29

25

26

The scale of the pulpwood sample work at Hohola led to the need for more assistance. Possibly the first indigenous females to be recruited by the Department of Forests were engaged. Misses Olwyn Kila and Jean Holmes commenced work as Laboratory Assistants under the supervision of Miss Lorraine Richardson. In the wood sample preparation work the team included Macdonald Wagapani.

With the woodchip export industry obviously developing, John Colwell considered that international pulp and paper industry experience could be useful. The result was the engagement of retired Canadian Industry executive, Mr. Larry Wickwire, who spent a year in New Guinea, lending his high-level support.

Although the pulping studies kept me busy until 1976 when I returned to Australia to join the Forestry and Timber Bureau in Canberra, there were numerous projects which I was able to assist with. These included providing advice to the Department of Public Works with improvements to their sawmill at Mendi in the Southern Highlands; log grading studies, an old-fashioned sort of project which took up a lot of time, although to my mind of little practical purpose; improvements in logging equipment, in particular wheeled skidders, by organising demonstrations for the timber industry.

Thinning and utilisation of stems from the Department of Forests’ Brown River Plantations was an interesting exercise. Some twenty-five truckloads of teak thinnings were brought into the Hohola site for processing into squared post material suitable for low-cost housing

25 Phillips F H and Harries E D 1975 The Pulping and Papermaking Potential of Tropical Hardwoods 1 CSIRO 26 Phillips F H, Logan A F and Balodis V 1975 The Pulping and Papermaking Potential of Tropical Hardwoods 11 CSIRO

structures which were proliferating on the fringes of Port Moresby and creating in Col Levy’s words, “an unsolicited demand”.

After the studies of mixed species pulping were completed by CSIRO, we embarked upon another significant study, this time of the pulping qualities of plantation grown species, primarily Eucalyptus deglupta - Kamarere. Fortuitously this study was facilitated by an interesting set of trial plots established in the vicinity of the Gogol Timber area near Madang. The trial involved plantation plots of Kamarere from several provenances.

We were able to complement the samples taken from the provenance trial plots with samples from a wide range of ages taken from plantations established over the years at Kerevat. The Japanese paper industry provided a complementary study of this species by taking a whole compartment (1957 planting from memory) which was shipped to Japan and converted into paper.

My decade working in the Forest Products Research Centre in Port Moresby was a highlight of my career. It allowed me to confirm, to myself at least, the amazing potential for forestry that resides in this land of Papua New Guinea. It also demonstrated to me the capacity of its people when trained, to deal with the complexities associated with a scientific approach to the use of forest products.

Establishing this institution was probably the most significant achievement of John Colwell’s career also. In his later years at Hohola the focus of his direction deteriorated. His health had seriously declined, and the Administration suffered from the inevitable anxieties associated with the achievement of National Independence. Sadly, there had been insufficient time for local officers to develop the maturity to cope with the technical complexities faced in this field. But I feel that the results obtained prior to Independence have proved of enduring value.

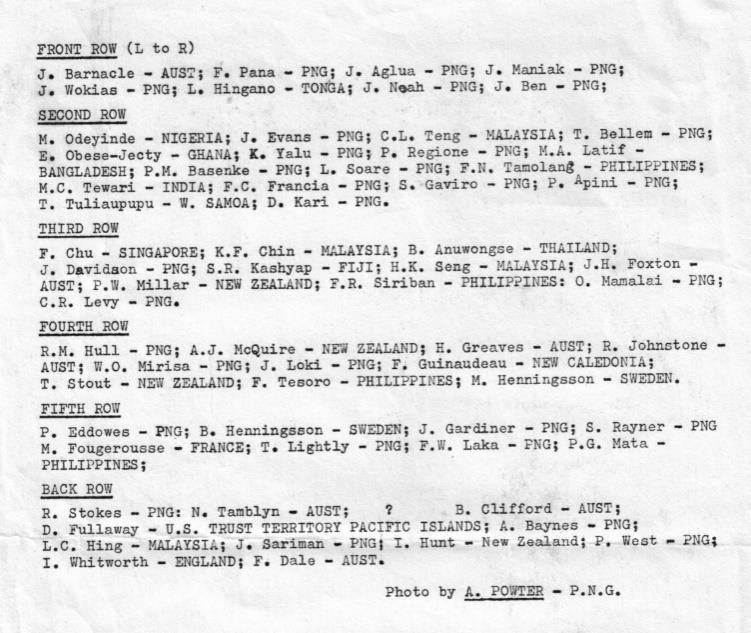

Source John Davidson Photograph 1976 Forest Products Research Centre, Dept of Forests, Hohola, Workshop on Wood Preservation in PNG.