3 minute read

Handling: Grenzebach

Dross box improves glass quality

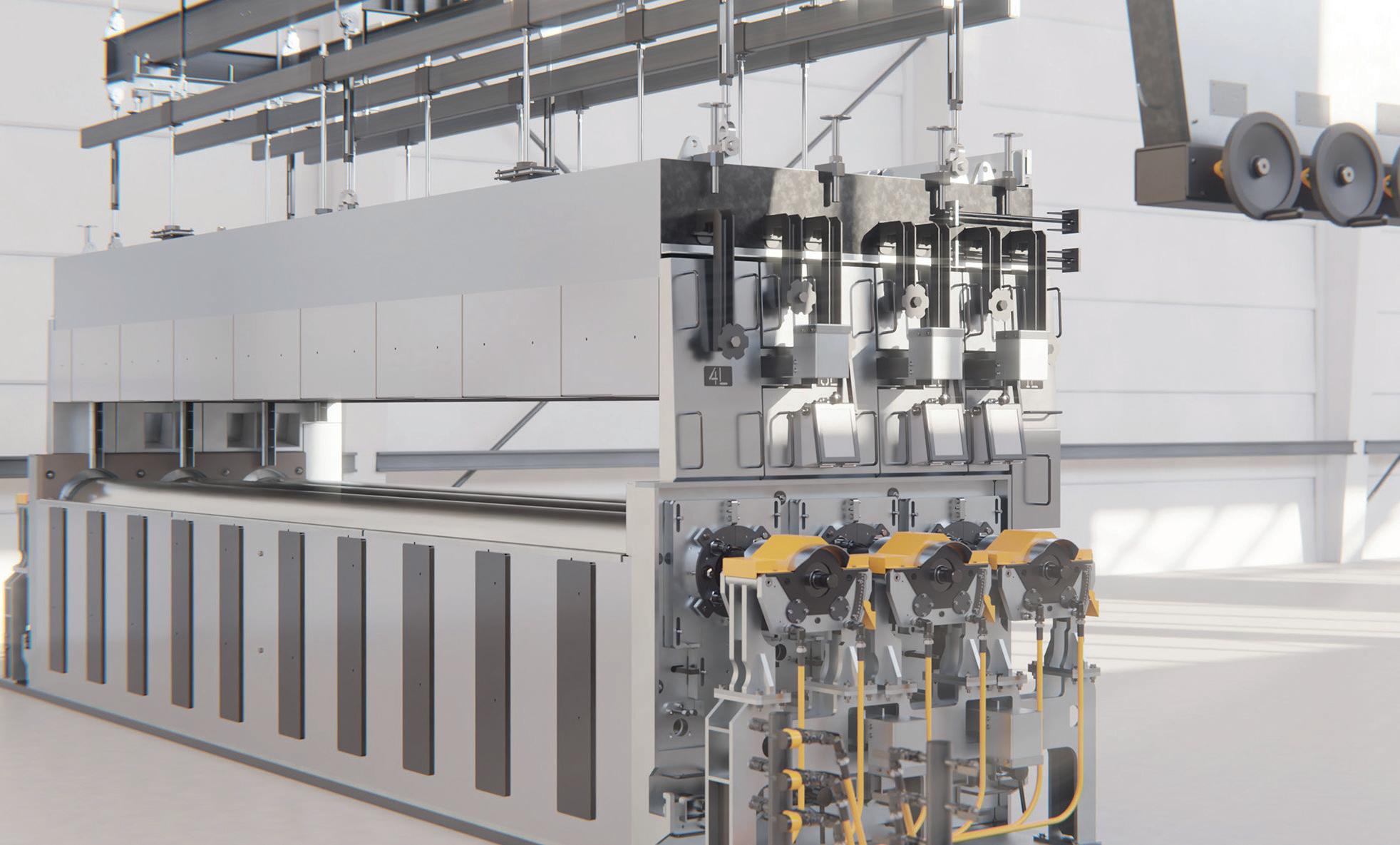

Franz Krommer* explains the benefi ts of Grenzebach’s new dross box, which include adjustable lift-out rollers, improved glass quality and a decentralised control system.

In fl oat glass production, the dross box is the interface and sluice between the tin bath and annealing lehr.

This point in the production process poses challenges because the glass ribbon, which is still very fragile, requires the utmost precision in handling under extreme ambient conditions.

The trick is to transfer the glass ribbon from a liquid and full-surface support to a roller conveyor. The Grenzebach dross box can master this tricky process step. Valuable process improvements are achieved with customisable roller technology, special roller sealing and safe maintenance options.

Roller technology

The rollers are the main features of the Grenzebach dross box. The glass ribbon, which is still fl exible, is lifted out of the tin bath by three individually driven rollers (LOR = lift-out rollers) and conveyed to the annealing lehr.

The lift-out rollers form a curve geometry, which can be adapted to the respective production requirements by individually adjusting the height of each roller. This also allows for an equal distribution of the load on all rollers. The result is a fl exibly adjustable lift-out curve with settings that can be optionally saved for the respective glass thicknesses.

The special roller sealing contributes to a particularly high level of insulation of the Grenzebach dross box. This results in less heat loss and a more homogeneous temperature distribution across the entire width of the glass (Fig 1).

The ambient temperature at the edge no longer substantially deviates from the temperature in the centre of the glass ribbon. This provides better glass quality and reduces the risk of a cross breakage.

The rollers are constantly cleaned over three-part graphite bars with pneumatically adjustable contact pressure to ensure a clean process.

Dross box housing

but attached to it by means of a clamping device, which is fi rmly fi xed after the tin bath has heated up to 620°C.

This way, thermal expansion is accounted for and deformations due to heat effects will neither occur on the housing nor on the U-channel (Fig 2).

� Fig 1. Grenzebach‘s dross box has improved glass quality through a more homogeneous distribution of temperature across the entire width of the glass. (Source: Grenzebach)

Maintenance and operation

The Grenzebach dross box can be locally and decentralised controlled with the user interface. During maintenance, operators benefi t from increased work safety and improved accessibility to the end plate and when changing rollers.

Rollers can be changed during operation. The resulting glass loss during roller exchange is minimal. Similarly, the graphite bar change can be performed quickly and easily in a very short time.

Additional features of the dross box: � Default design up to 650°C, optionally up to 850°C � Dross box for normal and extrawide fl oat lines � Retrofi tting of existing equipment possible � Injection of N2 and SO2 possible � Housing with stainless steel lining, insulated and gas-tight, including corrosion and SO2 protection � Retrofi tting of camera systems and illumination possible.

� Fig 2. Dross box housing – protected against deformations. (Source: Grenzebach)

Hot end

In addition to the dross box, Grenzebach customers also benefi t from an optimised annealing lehr with new design.

Building on the expertise of CNUD EFCO, Grenzebach has completely redesigned the annealing lehr and now offers a fl exible annealing point, improved process control, more precise simulations, and a reduced energy consumption.

Angus Farquhar, Field Engineer at CNUD-EFCO, said that the R&D team have reduced the lehr’s energy consumption by 70%. �

*Product Manager Business Unit Glass, Grenzebach Maschinenbau, Bavaria, Germany https://www.grenzebach.com/en/