17 minute read

Editor’s Comment International news

GREG MORRIS, EDITOR

Collaboration remains key for the industry

It feel like things have returned to pre-Covid normality in recent weeks with a fl urry of industry-related events.

Sector professionals were spoilt for choice with networking events in Thailand, Turkey, Belgium, UK and USA.

These get-togethers enabled executives to at last see each other face to face for the fi rst time in years.

Glass International attended as many events as feasible and - as always - it was a pleasure to reconnect.

One of the key themes around the world was that of collaboration.

The industry faces many challenges, particularly in its aim to reduce emissions from the production process, and many leaders acknowledge this will only be achieved by working in partnership with others.

This was exemplifi ed at the recent Glass Problems meeting in the USA. Scott Cooper, President of event organiser the GMIC, unveiled an alliance between several glass manufacturers which will focus on using green hydrogen to power the melting process.

And this was no lastminute plan as part of a speech to impress conference delegates.

The organisation had gained the ear of politicians several months beforehand during meetings in Washington D.C who had urged the organisation to seek further funding.

The industry is at last on the radar of senior fi gureheads, which in turn has opened inroads into funding to help enable the sector to decarbonise. FRONT COVER IMAGE: www.falornitech.com

Be fi rst with the news! For breaking, up-to-date news

VISIT:

www.glass-international.com

for daily news updates.

Image copyright: Coca-Cola

Coca-Cola returns to resuable bottles in currency crisis

Coca-Cola Beverages Sri Lanka will put a family-sized glass bottle back on the market to encourage reusable packaging and aid consumers in the currency crisis.

The Big Buddy Pack branded 750ml glass bottle is priced at 180 rupees, compared to 150 rupees for a 400ml PET bottle and 380 rupees for a 1.5 litre pack at supermarkets.

Sri Lanka is currently experiencing the worst currency crises in the history of its intermediate regime central bank.

Sri Lanka’s rupee collapsed from 200 to 360 to the US dollar in 2022, triggering monetary instability.

Annual infl ation is now running at around 70%. Food prices, which respond faster to money printing, are up to over 90% over the last year.

Panjak Sinha, Managing Director of Coca-Cola (Sri Lanka and Maldives), said: “It [the product] is affordable in these trying times and is differentiated with a unique refi llable glass bottle, paper labels and aluminium cap.”

Despite the latest bout of monetary instability, the fi rm will not leave the country.

The fi rm said it had invested $99 million in the country in the last decade and has built distribution network with 80,000 plus outlets.

Holophane enters insolvency after energy costs rise by 250%

French automotive glass manufacturer Holophane has requested to enter receivership after a spike in energy costs.

Its energy costs will be 250% higher this year.

It will be €10.5 million this year compared to an average of €3 million over the past three years.

The glassworks based in Andelys, Normandy, France specialises in the production of automotive fog lights and optics.

It also said demand for automotive lighting had declined in recent years in favour of plastic, which enables lighter vehicles.

By being in receivership the company can protect creditors as well as possible while continuing to look for a buyer.

According to the receivership notice, it has 241 employees at the facility.

O-I Glass sales increase by O-I Glass sales increase by $221 million in third quarter $221 million in third quarter

O-I Glass reported strong third quarter results for 2022 as higher average selling prices boosted sales by $221 million.

O-I reported its financial results for the third quarter which ended September 30, 2022.

Andres Lopez, O-I Glass CEO, said: “O-I reported strong third quarter performance which exceeded guidance driven by solid net price realisation as we began implementation of our third price increase this year in Europe.

“Our glass shipments increased slightly compared to the prior year period, as expected. Elevated asset project activity contributed to higher operating costs, as we commission much needed new capacity to support future growth.”

Net sales were $1.7 billion in the third quarter of 2022, up from $1.6 billion in the prior year quarter.

Higher average selling prices boosted sales by $221 million.

Shipments (in tons) improved nearly 1% but a less favourable mix resulted in a $4 million decrease to net sales.

Segment operating profit was $266 million in the third quarter of 2022 compared to $243 million in the prior year quarter.

Mr Lopez said the company would continue to deliver on key transformation initiatives.

O-I expects operating costs will be higher in the fourth quarter of 2022, due to incremental expense for expansion project activity.

However, this should be partially offset by benefits from the company’s ongoing Margin Expansion initiatives.

Israeli glass manufacturer Phoenicia will become carbon neutral by converting its CO2 emissions to soda ash, which will be reused in production.

Phoenicia signed an agreement with Airovation Technologies to install a unit that transforms CO2 emissions from its Yeruham plant into minerals that can be used in the glass production process.

After a decade of research at the Hebrew University of Jerusalem, Airovation has developed a method to capture sodium carbonate (soda ash) from CO2 at the point where the latter is emitted.

Extracting soda ash from CO2 is done by a patented chemical invention that uses Superoxide Radical, the most powerful oxidiser in nature.

Under the new partnership, Airovation will run a twophase scale-up process, eventually leading to the first fully commercial unit at the Yeruham plant.

This will reduce Phoenicia’s global warming carbon emissions, contribute to a circular economy, and reduce the company’s dependence on soda ash imports, an Airovation statement said.

Phoenicia CEO Michel Ben Simon said: “Phoenicia is thrilled to support an Israeli start-up and to co-operate in the execution of this pilot.

“The pilot represents a crucial step toward turning Phoenicia into the operator of the greenest factory in the State of Israel.

“It is also the country’s only factory capable of recycling broken glass bottles that are collected in accordance with the national deposit law, as well as a factory that works on natural gas, as we have built a natural gas power plant that should start working within two months.”

He continued that Phoenicia installed another facility a ten years ago to prevent the emissions of particles and nitrogen oxides.

NEWS IN BRIEF

Turkish manufacturer to invest in production line

Düzce Cam is to build a 600 t/day solar glass production line at its Bilecik Plant.

It signed an agreement with Chinese plant builder CTIEC to build the facility.

The site currently hosts a 300t/day solar line and will have a capacity of 900 tonnes when the new line is in place.

Iittala €10 million furnace investment

Fiskars Group will invest €10 million in electric furnaces for its Iittala glass factory in Hämeenlinna, Finland.

The investment will reduce the factory’s CO2 emissions by approx. 10,000 tonnes a year (74%) and decrease energy consumption of the melting furnaces by 67%.

The project will start next year and be completed in 2026.

Sustainable amber glass project

Researchers at the Freiberg University of Mining and Technology in Germany are investigating how to melt amber glass with green electricity instead of gas.

The goal of the research project, which officially starts on 1 January 2023, is the stable and reliable production of brown glass with green electricity from renewable sources.

The research project will be organised and funded by the project management organisation AiF-IGFForschungsvereinigung for the next two years.

Verallia France appoints Chairman

Verallia has appointed PierreHenri Desportes as Chairman of Verallia France.

With extensive experience in the industrial sector, Mr Desportes took over as head of the group’s French subsidiary on November 2, 2022.

Verallia Group CEO Patrice Lucas wished him success in his new role.

NEWS IN BRIEF

Verallia and Mahou energy partnership

Verallia Group and Spanish beer brand Mahou San Miguel have partnered to reduce CO2 emissions at their plants in Burgos, Spain using thermal energy recovery systems.

The two companies’ energy efficiency project uses untapped heat from glass production at Verallia’s plant to generate steam at Mahou’s brewery.

To date, Verallia has saved 175 tonnes of CO2 per year by using steam.

SEFPRO’s sustainable investment

SEFPRO’s furnace cooling systems at its SEPR plant in Le Pontet, France will reduce its gas consumption and CO2 emissions by approximately 500 tons.

The systems for furnace cooling, as well as a dust collector, will reduce the SEPR’s plant water consumption by at least 100,000m3 per year.

Fives commissions PV lehrs to China

Fives has put forward more than 16 annealing lehrs into operation for a photovoltaic (PV) manufacturer in China over the last few months.

The annealing lehr for extra-large glass ribbons, features Fives’ technology and engineering efforts of the local team in China.

It has a production capacity above 300 MT per day.

Vidromecanica relaunches website

Vidromecanica has relaunched its website to reflect its different equipment ranges.

The updated site’s new design allows customers to find the equipment they’re looking for more easily and provide online feedback.

The website provides information for glass plant managers and directors, from hollow glass to tableware glass factories, looking to supply their plant.

The NSG Group and SaintGobain have started a manufacturing furnace in Argentina.

Its Argentine subsidiary, VASA Vidrieria Argentina launched the furnace on Saturday October 8 at the weekend at its Planta Cardales site.

The plant, located, approximately 70 kilometres northwest of Buenos Aires, will have an estimated production of 900 tonnes per day.

It will supply architectural glass for the domestic market as well as export to countries in the region.

Founded in 1938 and the result of the association of two of the largest glass manufacturers in the world: NSG Group – Pilkington and Saint-Gobain, VASA implements advanced technology in the manufacture of a range of products.

VASA contains around 500 employees and is present with operations in four countries: Argentina, Bolivia, Paraguay and Uruguay.

Vidrala to raise prices after gas costs hit profit

Vidrala plans to raise the price of its bottles after soaring natural gas costs hit its profitability in the first nine months of the year.

Vidrala’s net profits have fallen due to increasing natural gas prices.

Despite its revenues rising 24% in January-September from the same period a year ago, its net profit per share fell 37%.

The company said the higher bottle prices will help gradually raise its operating margin in the fourth quarter.

Vidrala expects earnings before interest, taxes, depreciation, and amortisation to represent 20% of sales in the fourth quarter up from 15.6% in the first nine months this year.

Higher bottle prices will feed into Spanish inflation, which has dipped over the past two months from a three-decade high of 10.8% in July.

O-I Alloa secures approval for air separation plant

A UK glassworks has secured planning permission for the installation of an air separation unit.

The O-I Alloa facility, UK said the unit will separate air into oxygen, nitrogen and argon using a distillation process with storage on-site.

Much of the oxygen will be piped straight to the glassworks to fuel upgraded oxy-fuel furnaces. The move will reduce carbon emissions and ensure the viability of the business, which employs hundreds of people.

The unit will be installed by Air Products industrial gases group.

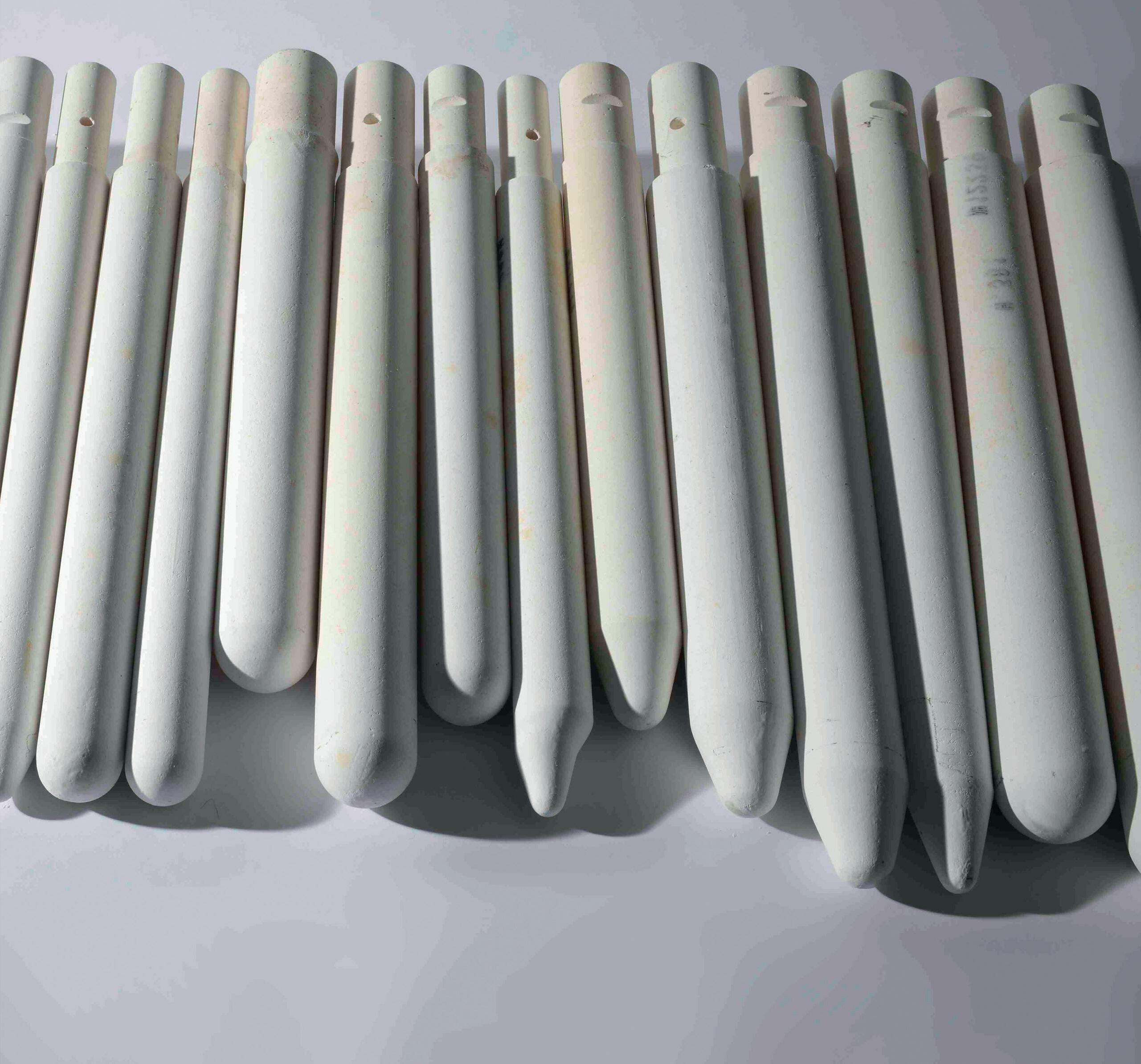

PSR FEEDER EXPENDABLES

50 years of consistency and reliability.

NEWS IN BRIEF

GMIC director says farewell to industry

Bob Lipetz said farewell to the glass industry after 12 years at the helm.

Mr Lipetz, the Executive Director of the Glass Manufacturing Industry Council (GMIC) in the USA, said goodbye at the 83rd Glass Problems conference held in Columbus, Ohio, USA.

He will be replaced by Kerry Ward, who will join the organisation in January.

Milk bottle voted as UK packaging icon

The everyday milk bottle has been voted as the most iconic glass packaging in the UK.

As part of the IYOG celebrations, experts from the worlds of packaging, retail, manufacturing and plasticfree living were brought together to choose the UK’s top 10 glass bottles and jars.

The single pint reusable glass milk bottle won due to its instantly recognisable shape, perfectly suited design and sustainable, made-to-bereused credentials.

AGI Greenpac reports 66% revenue increase

Indian glass packager AGI Greenpac reported a 66% increase in revenue in its latest fi nancial report, driven by improved effi ciencies.

In its fi nancial results for the second quarter ending September 30, 2022, revenue from Operations stood at 513 crore, registering a growth of 66% on Y-o-Y basis.

Wheaton Brasil to use biogas for production

Wheaton Brasil will use biogas as an energy source for its glass manufacturing processes.

According to the manufacturer’s estimates, using biogas will reduce its annual CO2 emissions linked to the production of glass by approximately 7,000 tonnes.

This is equivalent to more than 50,000 trees planted over a period of 20 years.

Top 10 stories in the news

Our most popular news over the past month, as determined by our website traffi c. All full stories can be found on our website.

� 1. Duralex halts production due to energy prices � 2. Verallia to acquire Allied Glass for £315 million � 3. Sisecam highlights $4 billion investment at World Soda Ash conference � 4. Ardagh sets dates for construction of Brazilian glass facility � 5. Israeli manufacturer to produce carbon neutral glass � 6. NSG and Saint-Gobain starts Argentine glass manufacturing furnace � 7. O-I glass sales increase by $221 million � 8. AGI Greenpac’s acquisition of HNG put on hold � 9. Energy crisis forces French glass furnace to close � 10. German glass industry optimistic over gas prices

For the latest Industry News scan the QR CODE using your iOS or Android device

Ardagh expands glass capacity at South African plant

Ardagh Glass Packaging Africa (AGP – Africa) will invest in a third furnace at its Nigel production facility in Gauteng, South Africa.

The investment in a third furnace (N3) follows the recently commissioned Nigel 2 (N2) expansion and will further increase the facility’s capacity.

The expansion is expected to be commissioned in late 2023, well ahead of current standard lead times.

Following completion, the Nigel production facility will be the largest glass container production facility in the AGP - Africa network, and on the African continent.

N3 will be a replica of the N2 expansion completed earlier this year and will similarly incorporate a new furnace and additional production lines.

It will also provide signifi cant energy, water effi ciency and environmental benefi ts, representing another important step in AGP – Africa’s journey to decarbonise the glass production process and reduce emissions.

This capital investment will further bolster the government’s economic recovery plans in Ekurhuleni, Gauteng, offering additional job opportunities and increased ancillary supply-chain benefi ts in the community.

Knauf Group plots €135 million Romania investment

The Knauf Group will increase its mineral wool production capacity in Central and Eastern Europe with a €135 million investment.

As well as retrofi tting the existing plant, which was acquired earlier this year, Knauf Insulation plans to expand its presence by building an additional insulation facility.

The investment will allow the company to increase its annual production output to 75,000 tonnes of mineral wool every year.

The new facility is scheduled to be completed by 2024.

It will create more than 100 new jobs and hundreds of additional jobs for regional suppliers, contractors and vendors.

The existing Romanian plant in Târnaveni, MuresCounty, has already undergone a series of upgrades and has been brought up to date in line with Knauf Insulation’s manufacturing standards.

NEWS IN BRIEF

Steklarna Hrastnik set for Serbian takeover

Steklarna Hrastnik, through its Swiss owner GlobalGlass, is set to take over the SFS Paracin factory, in Serbia.

The Paracin factory was in bankruptcy before the takeover and was the subject of a national programme for the revitalisation of the glass industry in Serbia.

The GlobalGlass group will increase its production capacity (by around 300 tons/ day) and its range of products.

German optimism over gas prices

The glass industry in Germany is cautiously optimistic following the release of an Interim report of the Gas Commission in Berlin.

BV Glas President Dr. Frank Heinricht is now hoping for a timely implementation through politics.

Watlow completes acquisition of Eurotherm

Watlow completed its acquisition of Eurotherm from Schneider Electric on October 31, 2022.

Eurotherm said Watlow’s industrial technology and its own precision control would offer complete thermal control loop solutions.

Watlow will establish Eurotherm’s sites in Worthing, UK and Dardilly, France as Advanced Development Centres for its electronics and controls product offering.

Ardagh to increase cullet use with Briquette Project

Ardagh plans to commercialise its Briquette Project, which will create more usable material for furnaces and reduce CO2 emissions.

The project is now in the final stages of being commercialised, and should be fully commercial by 2023.

Using cullet could help Ardagh reduce its Scope 3 emissions, of which 53% come from producing soda ash.

Visy breaks ground at $500 million Australia glass facility

Visy broke ground on its $500 million glass recycling and remanufacturing factory outside Brisbane, Australia.

The facility, which represents the largest investment Visy has ever made, will recycle up to 200,000 tonnes of Queensland’s glass annually to produce 1 billion bottles a year.

The site is expected to be operational in 2025.

Visy Executive Chairman Anthony Pratt said: “Recycling is an important weapon against climate change and the technology employed in this factory will help Australia to go from an average of 30% recycled glass content in bottles to 70%, which is moving towards world’s-best practice.”

The facility, in Stapylton just south of Brisbane, will be built next to Visy’s current box factory and beverage can plant.

It will support approximately 200 green collar manufacturing jobs once operational, and will bring Visy’s Queensland workforce to more than 1000 people.

The project will also create over 600 jobs in construction.

The project is underpinned by a long-term partnership with Asahi Beverages, and agreements with Visy customers including Lion, Bundaberg, and Coca-Cola.

This facility brings Visy’s total investment in Australia to over $11 billion.

Visy will relocate its glass remanufacturing operations from South Brisbane in 2025.

Energy prices forces Duralex to halt glass production

Duralex put its only furnace on standby on November 1 due to soaring energy prices.

The furnace, located in La Chapelle-Mesmin, in the Loiret, France will remain on standby for at least five months.

José Luis Llacuna, President of Duralex, said: “The price of energy usually represents 5% to 7% of our turnover. Today, it is around 40%. It is not tenable.”

The company said its energy bill had gone from €3 million euros last year to €12 million this year.

Duralex announced the site’s standby at the beginning of September.

The time between the announcement and its implementation is explained by the complexity of the operation: in theory, a glass furnace never stops to prevent being damaged.

“The oven will not be stopped purely and simply, but we will keep it at temperature so that we can restart it,” said Mr Llacuna.

As the company now has sufficient and quality stocks, it believes that it can continue its commercial activity normally during this period and thus continue to serve its customers satisfactorily.

Therefore, the site will continue to operate, with full activity resuming next year.

“We have a tariff cover already contracted on electricity, which will allow production to resume in the second quarter of 2023.”

Verallia to acquire Allied Glass

French glass packager Verallia is to acquire Allied Glass in a £315 million agreement.

Established in 1874 and headquartered in Leeds, Allied is a UK-based manufacturer of glass packaging containers for the premium spirits, food and drinks markets.

It has four furnaces and 600 employees.

It has modern extra-white, bespoke colour and decoration capability, with a strong focus on sustainability, based on an ESG policy with clear targets across all areas and a market leading use of cullet across all products.

Verallia said the acquisition will enable it to benefit from Allied’s expertise in premium glass bottles, specifically in the Scotch Whisky and Gin sectors, and from its established position on the UK market.