9 minute read

CASE STUDY: Advanced Tricology and Wear Research

Dr. Jiahui Qi, The Sorby Centre for Electron Microscopy, School of Chemical Material and Biological Engineering, The University of Sheffield

Institution:

Tribology and Wear Lab, School of Chemical Materials and Biological Engineering, The University of Sheffield

Research Focus:

The Tribology and Wear Lab at the School of Chemical Materials and Biological Engineering, University of Sheffield, is recognised for its expertise in the high-resolution characterisation of microstructures, especially surfaces and interfaces The lab’s research programs, led by Professor Rainforth, cover a wide array of materials science fields, focusing on developing new, high-strength materials and understanding surface phenomena that occur during wear and friction processes. The lab is integral in developing superior materials for medical implants, aerospace and manufacturing industries.

High-resolution Transmission Electron Microscopy:

The lab utilises this advanced technique to study atomic structures, particularly at interfaces found in nanoscale multilayer coatings and functional ceramics. This research is critical for improving the performance of materials in demanding environments.

Tribocorrosion and Tribochemistry:

A significant portion of the lab’s research is dedicated to understanding the dynamic microstructural changes that occur due to tribological contact, such as friction and wear, in both metallic and ceramic systems. The focus is on how these processes activate chemical or electrochemical reactions at the surfaces, leading to wear and corrosion in materials like hip arthroplasties and zirconia ceramics.

Wear and Friction in Biomedical Devices:

The lab extensively studies the performance of materials used in biomedical applications, such as hip implants, focusing on how frictional contact and the biological environment contribute to surface degradation. This includes studying the synergy between wear and corrosion, particularly in materials like Ti-6AI-4V and CoCrMo alloys.

Oxidation and Surface Degeneration Phenomena:

The lab also investigates oxidation during processes like hot rolling in metals and hydrothermal degradation of ceramics. Understanding these phenomena helps in designing new alloys that are more resistant to surface degradation.

Microstructural Evolution During Metal Processing:

Research is conducted on metals like titanium, magnesium, and steel to understand how their microstructures evolve during processing. The goal is to develop new materials with enhanced mechanical properties for industrial applications.

NanoMegas results for Ar and open-air samples under 40N (A to F) and 90N (G to L) load. The top and 3rd panels (A to C, and G to I, respectively) shows BF images and corresponding crystallographic z-orientation, and phase maps superimposed with grain boundary, for the open-air samples. The 2nd and 4th panels (D to F, and J to L, respectively) presents the same maps for the Ar samples The colour keys for z-orientation maps are provided (M). The percentage fractions of measured phases are presented next to the phase maps (C, F, I and L), where green is HCP, red is FCC and cyan is amorphous The blue double arrows indicate the sliding direction and surface position, while the red arrows represent the applied load direction Schematic drawings in B, E, H and K illustrate the strain distribution from the surface to the bulk material.

Challenges Before NanoMEGAS

Prior to acquiring the NanoMEGAS system, the lab encountered limitations in quantitatively interpreting the nanoscale structural changes that occurred during tribological processes. While conventional methods like transmission electron microscopy (TEM) and electron backscatter diffraction (EBSD) offered some insight, they could not fully resolve the fine details of highly deformed structures at the nano-level Specifically, the team struggled to quantify dislocation densities and detect subtle phase transformations that influence friction and wear This lack of precision inhibited their ability to predict and improve material performance, particularly for biomedical implants where understanding the interplay between wear, corrosion, and protein interaction is crucial.

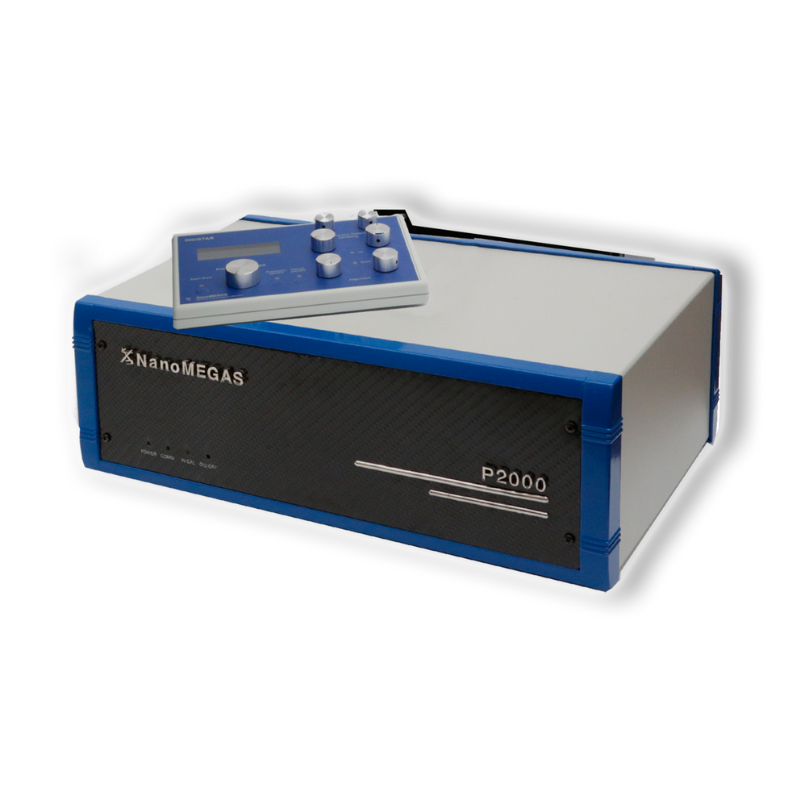

Why NanoMEGAS

Precession Electron Diffraction (PED):

NanoMEGAS provided a breakthrough with its precession electron diffraction technology, offering spatial resolution between 0 5–5 nm and an angular resolution of approximately 0.1°. This capability allowed the lab to analyse the ultrafine, nanocrystalline structures formed under severe tribological conditions, which were previously very challenging using conventional techniques.

Resolution of Complex Structures:

The ultrafine grain structures that develop in materials like Ti-6Al-4V and CoCrMo during tribocorrosion were difficult to characterise using traditional methods PED allowed the lab to accurately index different phases and calculate dislocation densities, providing a more comprehensive understanding of the deformation mechanisms at play.

ASTAR Software Integration:

NanoMEGAS’s ASTAR software enabled automated phase and orientation mapping, which was crucial for the lab to interpret the highly deformed structures efficiently. This software allowed the lab to correlate the nanoscale structural data with the wear performance of materials.

Ability to Quantify GND Density:

NanoMEGAS’s capabilities to obtain data are then used for calculating the geometrically necessary dislocation (GND) density This helped the lab evaluate the degree of deformation in different phases and under various tribological conditions. This allowed for more precise predictions regarding how materials will perform under wear and corrosion.

How NanoMEGAS Changed the Research

In one of the lab’s key research projects, NanoMEGAS played a vital role in understanding the microstructural evolution of Ti-6Al-4V and CoCrMo alloys during tribocorrosion tests conducted in a simulated body fluid environment. Tribocorrosion an interaction between wear, friction, and electrochemical corrosion has a significant impact on the performance of biomedical implants.

Using NanoMEGAS, the lab team was able to quantitatively measure the geometrically necessary dislocation (GND) density and characterise the formation of tribofilms The ability to measure deformation structures quantitatively at nanoscale precision was critical to uncovering how these tribofilms influence material wear resistance.

Results and Key Findings

NanoMEGAS enabled the team to achieve several key results that were unattainable with conventional techniques: Quantified GND density and identified nanostructural changes under different tribocorrosion conditions. Detected the formation of a protective tribofilm that reduced friction and wear, particularly under conditions with a positive potential and protein interaction.

User Experience and Support

Although the initial use of NanoMEGAS began without in-person training due to the COVID-19 pandemic, the lab was later able to reconnect with the NanoMEGAS support team for training and updates. The hands-on support significantly enhanced the team’s understanding of the system, allowing them to expand its application to more complex projects The training helped ease the challenges of data processing and interpretation, leading to more efficient use of the system.

Grain boundary (GB) superimposed on the geometrically necessary dislocation (GND) density distribution maps in the subsurface regions from the four selected testing conditions The scale bar is 100 nm on the PBS sample and is 500 nm for the remaining three samples The colour scale is log(GND density in m2) Arrows indicate the sliding direction and surface position.

Impact and Future Opportunities

NanoMEGAS has been transformative in enabling the Tribology and Wear Lab to conduct advanced research at the University of Sheffield. The lab is now exploring new research avenues, including in situ heating experiments in TEM to observe phase transformations in real time. The data gathered using NanoMEGAS will further contribute to the lab’s ongoing research into wear-resistant materials and their application in biomedical and industrial sectors.

The lab is also enthusiastic about collaborating with other institutions and industrial partners through the Henry Royce Institute at Sheffield, offering access to NanoMEGAS through the university’s Equipment Access Scheme.

NanoMEGAS has been transformative in enabling the Tribology and Wear Lab to conduct advanced research at the University of Sheffield. The lab is now exploring new research avenues, including in situ heating experiments in TEM to observe phase transformations in real time.

The data gathered using NanoMEGAS will further contribute to the lab’s ongoing research into wear-resistant materials and their application in biomedical and industrial sectors The team is keen to host future workshops to share knowledge and promote the system’s capabilities to the broader research community.

Conclusion

NanoMEGAS has proven to be an indispensable tool in advancing our understanding of tribological processes at the nanoscale. Its ability to precisely characterise microstructural changes has provided invaluable insights into material performance in a wide range of applications.

For more information or collaboration inquiries, please contact the Sorby Centre for Electron Microscopy at i.ross@sheffield.ac.uk or visit The University of Sheffield Electron Microscopy Facility

Learn more about NanoMEGAS on our website

---------------------------------------------------------

Contact Quantum Design UK and Ireland:

Get in touch with our Technical Director, Dr. Shayz Ikram by email, or call (01372) 378822.

List of publications: 1) Qi J, Cole T, Foster A & Rainforth WM (2024) Tribocorrosion behaviour of CoCrMo in simulated body fluid under anaerobic conditions. Wear, 556-557, 205523-205523. 2) Qi J, Ma L, Gong P & Rainforth WM (2023) Investigation of the wear transition in CoCrMo alloys after heat treatment to produce an HCP structure. Wear, 518-519, 204649204649. 3) Qi J, Guan D, Nutter J, Wang B & Rainforth WM (2022) Insights into tribofilm formation on Ti-6V-4Al in a bioactive environment: Correlation between surface modification and micro-mechanical properties. Acta Biomaterialia, 141, 466-480. 4) Xu Y, Qi J, Nutter J, Sharp J, Bai M, Ma L & Rainforth WM (2021) Correlation between the formation of tribofilm and repassivation in biomedical titanium alloys during tribocorrosion. Tribology International, 163, 107147-107147. 5) Namus R, Nutter J, Qi J & Rainforth WM (2021) Sliding speed influence on the tribocorrosion behaviour of Ti6Al4V alloy in simulated body fluid. Tribology International, 160, 107023-107023.