4 minute read

IN-SITU X-RAY APPROACHES IN BATTERY RESEARCH

Overview

X-rays provide critical insight on failure mechanisms and lifetimes of energy materials because they can provide nondestructive measurements of structure, chemistry, and composition of batteries while they are running (in operando) or over time. Because of this, synchrotron approaches have been critical to the development of improvements to existing lithium ion batteries and for creating novel energy schemes such as lithium-sulphur and lithium-air batteries.

Sigray’s portfolio of x-ray systems enable some of the most cutting-edge research in novel battery formulations and materials, including changes to the chemistry, composition, and structure of batteries as a function of cycling.

-------------------------------

BATTERY BOND LENGTHS AS A FUNCTION OF CYCLING

XAS has become a gold standard approach for characterising structural and electronic information of electrodes, thereby providing an understanding of electrochemical mechanisms governing a given battery’s chemistry.

Sigray’s QuantumLeap enables both ex-situ determination of electrocatalyst chemistry and the use of in-situ cells to study chemical changes in-operando.

-------------------------------

BATTERY CHEMISTRY THROUGH XAS

Customers around the world are using the QuantumLeap for development of novel battery materials. Several of the groups are now publishing with high quality (K=12 or greater) XANES data. One example is a group at Shanghai Jiao Tong University (STJU), who reported advances in the promising Ni-Zn batteries by carbon dot coating of the ZnO anode materials to extend material lifetime.

-------------------------------

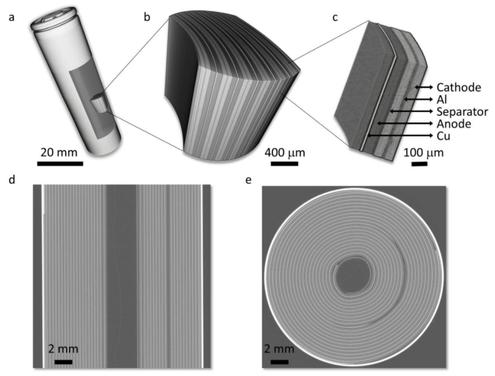

THE ROLE OF STRUCTURAL DEFECTS IN COMMERCIAL LITHIUM-ION BATTERIES

3D X-ray Microscopy has become a gold standard for investigating battery failures and the structural defects that cause them Shown to the right are various failures investigated with Sigray’s EclipseXRM in intact batteries More information and figures can be seen in the article below, published on Cell Reports and using EclipseXRM (previous generation was named PrismaXRM) for the xray microscopy images and AttoMap for the microXRF data.

-------------------------------

3D IMAGING OF INTACT BATTERIES AND BATTERIES IN-OPERANDO

Sigray’s EclipseXRM provides submicron high resolution even for large samples and samples placed within in situ cells. The flexibility of the EclipseXRM in switching between multiple fields of view allows hierarchical characterisation of batteries – from the full FOV to detailed region-of interest imaging – without requiring de-packaging the battery This allows non-destructive identification of problems such as small defects (cracks, particles) and shorts.

-------------------------------

TRANSITION-METAL PRECIPITATIONMAPPING

From Materials Today

High-nickel LiNixMnyCo1-x-yO2 (NMC) cathodes have emerged as a highly promising cathode candidate for next generation lithium-ion batteries (LIBs) Battery cell operation with a high cutoff voltage is another broadly adopted approach to increase energy and power density Unfortunately, the high-voltage cycling approach exacerbates the degradation of the NMC cathode, including the surface lattice reconstruction and transition metal dissolution Sigray’s AttoMap microXRF uncovers the diffused precipitation of Mn, Co, and Ni, as well as their spatial distributions on the lithium metal anode.

-------------------------------

CONTAMINATION IN BATTERY MANUFACTURING AND METAL MIGRATION

Thermal runaway is one of the primary concerns in lithium ion batteries (LIBs) that is often caused by an internal short circuit Such shorts can occur because of contaminants such as iron particles introduced during the manufacturing process Sigray’s AttoMap microXRF provides high sensitivity at rapid speeds (down to 2ms/point) to quickly screen for contaminants.

For R&D researchers, the AttoMap’s high spatial resolution and sensitivity enable imaging of trace-level metal migration in electrodes between battery cycling. The system complements XRD and XAS systems by providing the distribution of elements of interest at microns-scale resolution

Highlights

• Multiscale and 3D visualisation of structural defects in commercial batteries

• Elucidation of the impurity particles’ detrimental effects on the battery performance

• Functional mechanisms of structural defects in commercial batteries are summarised

Sigray develops laboratory instruments for studying microstructure, chemistry and composition. These instruments are enabled by patented ultra-high brightness x-ray source and high efficiency x-ray focusing optic technology.

Discover the X-ray Range at QDUKI

-------------------------

LET’S HAVE A CHAT

Discuss how Sigray can resolve your lithium ion battery challenges with our Technical Sales Manager, Dr. Luke Nicholls... Call: (01372) 378822 Email: luke@qd-uki.co.uk