2 minute read

HDPE Pipe in Mining – A Better Approach......................................................2

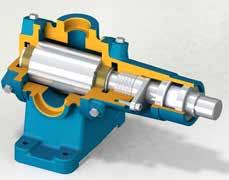

Yıldız Pompa manufactures internal eccentric gear pumps, magnetically driven gear pumps, modular gear pumps, helical gear pumps, vane pumps and lobe pumps for the transfer of viscous and semi-viscous liquids which are closely related to the industry.

Advertisement

The gear pumps produced by Yıldız Pompa are used in the following indusries:

Abrasives, Adhesives and Fillers, Agrcultural Products, Bitumen, Bio-Diesel, Drinks, Chemical, Chocolate, Etanol, Oils, Fiber, Food, Fuel ve Fuel Oil, Lubrication, OEM Applicatons, Petroleum Production, Oil Refinery, Paintand Coating, Personal Care Products, Medicine, Plastic, Polimers, Polyurathane Foam, Printing Inks, Paper, Cooling, Rubber, Soap and Detergent, Sugar etc.

Yıldız Pompa,which conducts production activities in modern R&D laboratoriesand modern technologal conditions, is the leader for the main industries where the use of products is offered. It is also gaining strenght in the country’s economy with the increase in the movement and employment provided by the industrial sector, which is within the production target , in the important sector.

Yıldız Pompa continues its claim with the capacity to produce all kinds of gear pumps that our industry needs with its experienced and experienced staff in production and sales and with the standard of reliable service that does not compromise on quality.

Yıldız Pompa, which combines quality production and excellent workmanship with timely delivery and after-sales support, has been a leader in a short time.

Yıldız Pompa serves every nation’s customers with its European quality pumps at competitive prices. Yıldız Pompa’s main principle is constantly improving. We produce pumps at high quality with modern technological machinery. Our goal is to increase customer satisfaction with our design, product range and after-sales services.

Yıldız Pompa employs 40 personnel, all of whom are well-trained and qualified mechanic operators and montage technicians. There are 6 engineers who support production.

Our indoor area is approxiamtely 5000 m2. 3D design programs are used in R&D. High-tech machines such as CE Axial CNC Lathe, Horizontal Machining Center and CAM program are used in manufacturing area. Our annual output is about 3500 pumps.

We manufacture in ISO 9001 standards. Our products are CE certificate.

Our countless pumps are working successfully in Turkey and in the World industries. It will be given to those who are interested in special request, since it will be impossible to give a long reference list here.

Sustainability is everyone’s responsibility Running a more sustainable, energyefficient food and beverage manufacturing plant takes work and needs both clear decisions from senior management and commitment from all levels of the organization. By prioritizing energy and water conservation, identifying the areas that need the most attention, and committing to energy and water saving initiatives, manufacturers can have a significantly positive impact on sustainability, which invariably results in reducing costs and making an organisation more competitive.