8 minute read

FEATURE Contract Winemaker reaching capascity

Contract Winemaking

Contract winemakers reaching capacity

Fighting a battle with the red wine glut

As the wider wine industry battles challenges like staffing and wine storage, contract winemaking services have been hit with a larger than usual stockpile of grapes and wine. Harrison Davies writes about how the contract winemaking sector is contending with more wine than it knows what to do with and fewer hands to handle it.

Image courtesy Project Wine

Contract winemaking services are offered across the country by wine businesses large and small. For some it’s a way of incorporating somewhat of a ‘side hustle’ to the business whilst for others it’s their bread and butter.

As with most other facets of the wine industry, contract winemakers have seen an uptick in work due to a shrunken, post-COVID workforce as well as a glut of red wine.

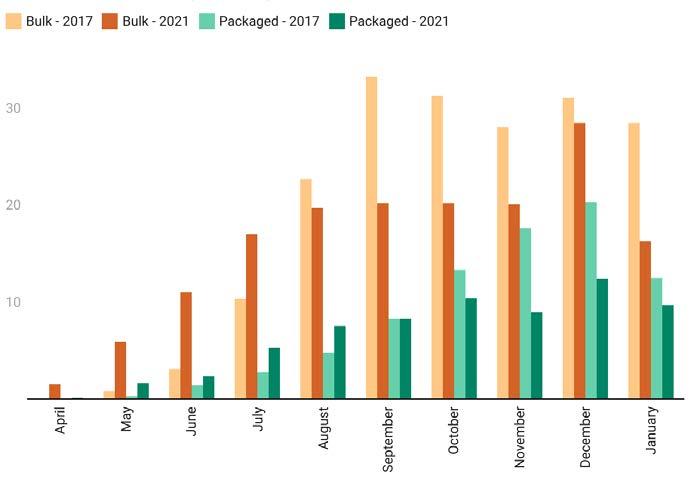

This demand is a blessing and a curse for contract winemakers, who now have more work than ever but can also only produce so much. The glut of red wine has meant that contract winemakers are also struggling to provide storage for all the wine that is being made at their facilities. A lack of wine storage has been an issue for most of the year and began cropping up amid shipping woes and supply chain blockages at the start of the year. A report released by Wine Australia detailed the delays and showed how the big vintages seen in 2021 were contributing to a lack of space in 2022 (see Figure 1 on page 68). For the report, they spoke with Mads Aaboe, regional director of Hillebrand Oceania, about how delays in Southern California and China were affecting producers in Australia. “The ports of Oakland, Long Beach, Seattle and Vancouver all have their individual challenges with congestions and backlogs. In addition to this, there will be numerous blank sailings for vessels into the port of Oakland from February to May, which is traditionally the main port for imports of Australian wine,” Aaboe said.

“Depending on the specific situation there might be additional trucking costs, wharf/depot storage and container detention. It all depends on if containers are gated into the port or sitting in storage in a holding yard.” The impacts of these delays meant that wine that was supposed to go to export at the start of the year had to stay in storage at the start of Vintage 2022 and now wine from the most recent vintage has fewer places to be kept.

“Delays at overseas bottling plants are also occurring, due to the erratic vessel schedules which delay or accumulate vessel arrivals. This puts pressure on the bottling plants to accommodate sometimes large waves of containers, which in turn causes containers to attract wharf/yard storage and container detention costs as they await a slot for unloading,” Aaboe said.

New demands

Project Wine is a contract winemaking service based in Langhorne Creek. Senior winemaker Peter Pollard said there had been enquiries from many growers who previously had only grown grapes but were not interested in making their own wine with their surpluses of red varieties.

“There have been many enquiries from growers who have previously just sold their grapes, about the prospects of processing surplus reds and speculating on the bulk market,” he said. “I have no doubt there will be more enquiries in coming vintages, particularly from growers with red grape surpluses. Some of these enquiries may present new opportunities, but only if the fruit and subsequent wine made is high quality and the resultant wine is priced sensibly for sale.

“Certain regions will have more currency in the bulk market than others and these may be worth consideration to speculate from a bulk wine perspective. “But generally given the current market conditions, unless all your tanks are empty, there will be no point filling up a winery with surplus red that may take an extended period of time to move.

“This only perpetuates the red wine oversupply, while potentially giving the industry a false impression on the size of the challenge. He said with more enquiries coming in, the challenge of providing enough space for red wine could become a more pressing issue as the industry moves slowly into vintage 2023. “Contract processing space will generally be tight heading into vintage 2023, although this does depend upon the type of processing required. “This is based around most producers requiring grapes to be processed to a finished wine, with ongoing storage requirements.”

Volume (million litres) of 2017 and 2021 vintages shipped in months following vintage. Source – Wine Australia

Mads Aaboe

Peter Pollard

Part of the challenge for companies like Project Wine is balancing service to existing clients whilst still having a capacity to extend their business to new customers.

Pollard explained that as wineries are carrying higher than normal inventory levels, it has caused increased pressure on tank storage availability. Existing clients who have always used contract services already have space allocated. “For new producers considering entering the market, they would want to be organised and discussing potential requirements now, so processing space can be allocated and logistics worked through,” Pollard continued. “With increased inventory levels being carried by many wine businesses, wineries are generally at capacity and needing to outsource some additional storage to open up processing space for the next vintage. “It may be too late to make a last minute processing call, if plans have not been put in place earlier.” Annual challenges, like staffing wineries prior to vintage and gauging consumer demand, are inflated by the reality of the lack of space in wine storage. Despite a potential shortage of wine storage space, Pollard remained confident that the industry would find solutions ahead of Vintage 2023. “Contract winemaking sites continue to offer growers/producers alternate options for processing fruit, either for branded products or bulk wine avenues,” he said.

“While the upcoming vintage will be challenging, contract sites will play an important role in providing quality winemaking services to the industry now and into the future.”

TheThe Cellar-MateCellar-Mate can’tcan’t makemake thethe coffee...coffee...

B Bu ut t itit cancan autautomatomaticallically y fifillll tantanks,ks, rackrack tanks,tanks, fillfill barrels,barrels, emptyempty barrels,barrels, prprepepareare b blenlend ds,s, filfill l tatanknkers,ers, feefeed d f fililters,ters, carrcarry y outout p pumump p o ovevers,rs, fifil ll l f flexlex cocontaintainers..ners.. . .

ThThe er re e i is s a a b be ettetter r waway y! ! T Te el le ep ph ho on ne e 0 03 3 9 94 45 55 5 3 33 33 39 9 F Fa ax x 0 03 3 9 94 45 59 9 5 52 23 32 2 E Em ma ai il l: : r ra ap pi id df fi il l@ @r ra ap pi id df fi il l. . c co om m. . a au u W We eb b: : w ww ww w. . r ra ap pi id df fi il l. . c co om m. . a au u

The Cellar-Mate can’t make the coffee... The Cellar-Mate can’t make the coffee... The Cellar-Mate can’t make the coffee... The Cellar-Mate can’t make the coffee... The Cellar-Mate can’t make the coffee... The Cellar-Mate can’t make the coffee... The Cellar-Mate can’t make the coffee...

But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers... But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers... But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers... But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers... But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers... But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers... But it can automatically fill tanks, rack tanks, fill barrels, empty barrels, prepare blends, fill tankers, feed filters, carry out pump overs, fill flex containers...

ThereThereThereThereThere Thereisisisisis isa bettera bettera better a bettera better a betterThere is way!way!way! way!way! way!a better way!

Email:Email:Email: Email:Email: Email: Telephone 03 9455 3339 Fax 03 9459 5232 rapidfil@rapidfil.com.au Web: www.rapidfil.com.au Telephone 03 9455 3339 Fax 03 9459 5232 rapidfil@rapidfil.com.au Web: www.rapidfil.com.au Telephone 03 9455 3339 Fax 03 9459 5232 rapidfil@rapidfil.com.au Web: www.rapidfil.com.auTelephone 03 9455 3339 Fax 03 9459 5232 rapidfil@rapidfil.com.au Web: www.rapidfil.com.au Telephone 03 9455 3339 Fax 03 9459 5232 rapidfil@rapidfil.com.au Web: www.rapidfil.com.au Telephone 03 9455 3339 Fax 03 9459 5232 rapidfil@rapidfil.com.au Web: www.rapidfil.com.au Telephone 03 9455 3339 Fax 03 9459 5232 Email: rapidfil@rapidfil.com.au Web: www.rapidfil.com.au

Image courtesy Project Wine

Call us to arrange a demo Call us to arrange a demo Call us to arrange a demo Call us to arrange a demo Call us to arrange a demo Call us to arrange a demo Call us to arrange a demo