7 minute read

Achieving sustainability by design

GREEN MARITIME TECHNOLOGY I PROFILE

ACHIEVING SUSTAINABILITY

Advertisement

BY DESIGN

As the marine industry continues to square up to its responsibilities on sustainability, companies such as Green Maritime Technology are only too willing to provide innovative solutions to help ship owners and operators. Focused on marine engineering and naval architecture services, GMT offers concept to installation, with Managing Director Pantelis Avlonitis asserting: “Tackling the challenges of environmentally friendly shipping operations is our mission.” Profile by Andy Probert.

Established in 2014, Green Maritime Technology was, as the title hints, set up to address a growing need to provide environmental solutions and consultancy services to ship owners.

“With our design and engineering experience, we decided to focus on providing green, as we saw a need in the sector,” commented Managing Director Pantelis Avlonitis. “Our innovative approaches seek to improve shipping’s environmental performances and lower their operational costs.”

Grown rapidly

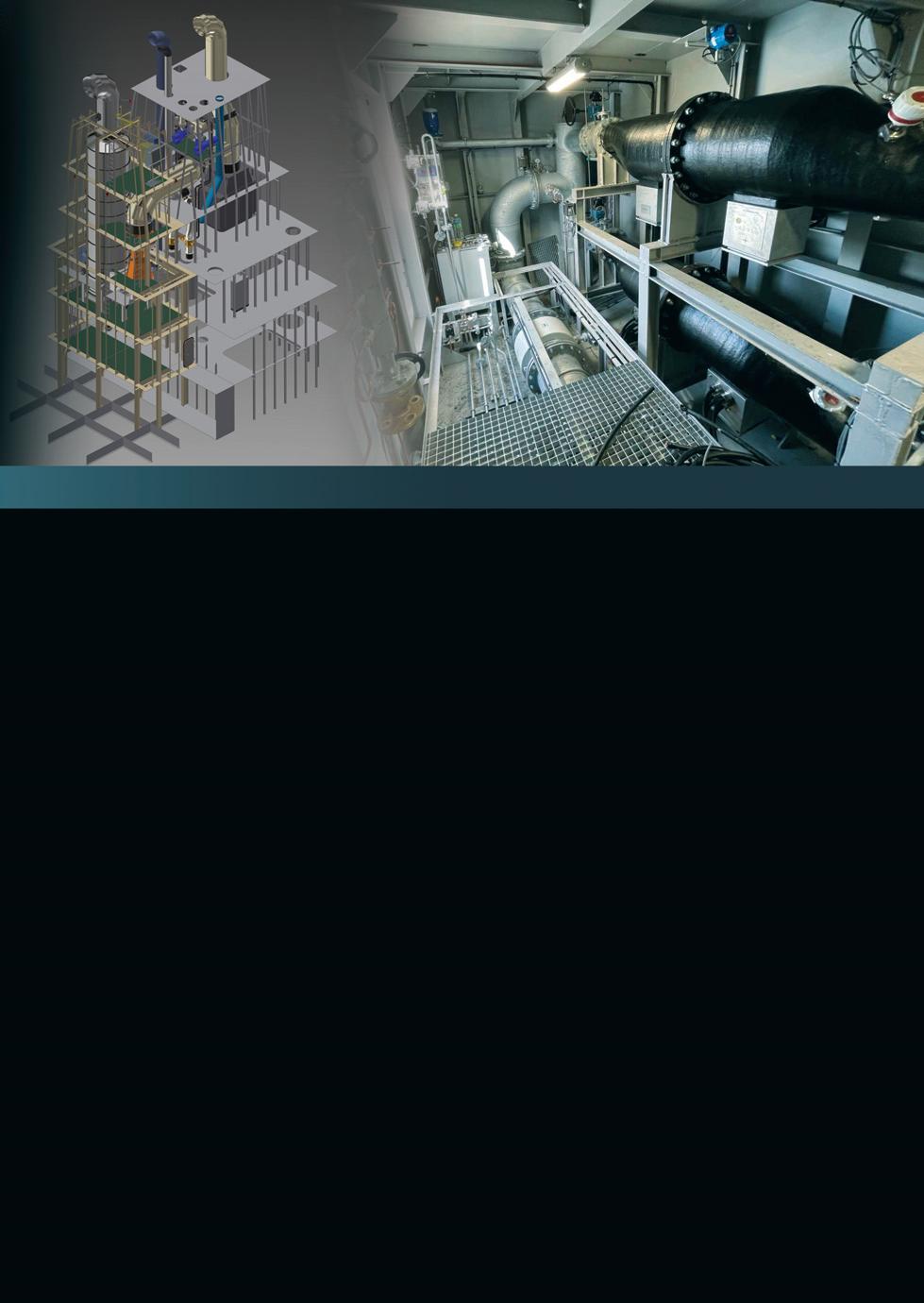

GMT’s services cover a wide range of engineering fields, notably 3D modelling, 3D laser scanning, design and implementation services, retrofitting feasibility and engineering studies, such as ballast water treatment systems and scrubbers, and new build designs.

With offices in Athens, Greece, and Limassol, Cyprus, GMT has accumulated nearly 170 clients, 60% from Greece and 40% from abroad. On the project side, the almost 50-strong workforce has completed in excess of 320 projects, 560 3D scan surveys and over 600 vessel assessments.

“We have grown quite quickly since our start-up, with 2018 and 2019 notably posting growth of 40%,” reflected Mr Avlonitis. The company has continued stable growth across the pandemic, but plans to open an office in Miami, Florida, to cater to the cruise sector have been put on hold until the global industry recovers.

Notably, GMT has completed 1100 retrofit ballast water system solutions for a host of vessel owners.

“A recent industry survey estimated about 35,000 vessels have yet to be fitted

with either scrubbers or ballast water treatment systems,” reported Mr Avlonitis. “So the next two years will be hectic, and GMT is very keen to offer its services.”

Optimise design and installation

GMT’s projects have been mainly focused on tankers, bulk carriers, container vessels, general cargo vessels and cruise vessels. It is expected to complete around 350 projects in 2022 compared to 200 in 2019.

“We have also developed excellent relations with two major companies; EcoSpray for their high-tech scrubber solutions, and Wärtsilä Voyage,” acknowledged Mr Avlonitis.

“When GMT began, it was more focused on the systems’ designs. But now we have expanded, and we can offer the complete installation of a BWTS. Offering an excellent combination of design, engineering, fabrication and installation means a client can come to us for the entire process.”

GREEN MARITIME TECHNOLOGY I PROFILE

GMT’s teams are usually deployed onboard and carry out installations during sailing and finish within a 10 to 12 day timeframe, without impacting or interrupting the vessel’s voyage.

“Our teams have also travelled to Turkey, the Netherlands, South Korea, Portugal and the Middle East to complete the projects,” Mr Avlonitis said. “These jobs are done in collaboration with quality sub-contractors worldwide.”

He added: “We are one of the few companies that can complete onboard installations and have finalised many projects. We optimise the design to ensure a rapid and trouble-free installation of the ballast water system.”

The company is also concerned with the research and development of new technologies concerning IMO regulations on fuels, studies, assessment and design of mid-ship vessel expansion, vibration and modular analysis, resultant modification proposals and solutions in container ships, and conversions from bulk carriers to container capacities.

GMT conducts 3D scanning and modelling for component arrangement and piping of competing systems, pre-selected by the owner. A clash detection process is performed for every system to minimise the interference with existing structures and outfitting arrangements.

A detailed feasibility report is also delivered as part of the package, and after a system’s selection, an engineering study is conducted moving forward to completing the installation process.

GMT also offers solutions for energy efficiency improvement, with the 3D design of ESDs via advanced systematic CFD calculations and modification options ranging from propeller hub cap fins, inflow improving ducts and pre-swirl stators.

“We are continuing to expand our expertise in other areas, and we hope to bring those to the fore during 2022,” added Mr Avlonitis, noting that the aim was to continue to attain double-digit growth.

“We do expect growth to continue in the next two years on the BWTS and scrubber side of the business, and from 2023 we expect more focus on the environment and emissions, something that will significantly affect the maritime industry.”

Financially secure

He said: “We have enjoyed 25-30% growth per year and up to 40% over the pandemic period. We carried out many investments when we started GMT, such as buying four advanced scanners.

“When we started GMT, we didn’t have any loans, so there were no problems with the banks. GMT is a €6 million turnover company and operates in a very financially-secure environment, even with the impact of Covid.”

He added: “Considering the impact of new regulations, we see growth opportunities in key areas like cold ironing, 3D printing, and solutions to comply with EEXI and CII. We plan to achieve these through strategic partnerships with key industry stakeholders to provide solutions to our clients.”

He commented: “One focus is to continue developing collaborations with important manufacturers worldwide on new products. We are also investing in new designs and plans to bring forward patents in innovative technologies for the benefit of clients and the wider industry.”

Mr Avlonitis confirmed finding the right qualified employees remains a challenge in advancing GMT’s mission and expanding the company.

“It’s obvious you need proper engineers to expand your service profile, but it is a problem faced by many companies worldwide. We believe we have the right mentality and background to offer highquality services to clients.”

Transparent approach

Mr Avlonitis said he is of the strong opinion that it is better to offer exceptional service and work with specific owners, than to expand services too much and have a lot of clients with the sole aim of increasing profitability.

“GMT’s position in the market is very strong with robust client relationships underpinned by open and honest communication. Because of our company structure, a client can pick up the phone and talk to anyone within the office and will get an answer to their questions immediately.

“Direct communication and a 24/7 response are important to us, but we also follow up and offer after-sales support. We don’t just walk away when a project is finished: Green Maritime Technology wants to encourage a continuous and harmonious working relationship with clients over the long-term.”

GMT, confirmed Mr Avlonitis, prides itself on the personalised services it provides.

“We don’t operate on the one solution fits all approach, and tailor services to their needs. I think this, along with a prompt reply and on time delivery, is a key to our success.”

He went further: “Irrespective of whether it is a client or a supplier we are dealing with, the fundamentals of creating a good relationship and maintaining that over time are pretty much the same. Most importantly with all stakeholders is to make them feel we are part of the same team, and we are all working towards the same objectives and deliverables.

“With suppliers, it is important to communicate effectively, making sure they understand the scope of work and what our expectations are in meeting all deliverables on time at the agreed cost.”

At GMT, the company’s commitment to sustainability goes beyond ISO 9001 and 14001 certifications.

“We are committed to the development of our people, both as professionals and individuals,” underlined Mr Avlonitis. “As a service provider, we are not directly involved with improvements in environmental performance. But we are very proactive in our mission towards helping our clients achieve better environmental performance through our engineering designs.”

Whether it is a design of BWT systems, scrubbers, or onboard installation of a BWTS, GMT’s recommendations always take into consideration the resources and carbon footprint of different solutions.

“We then work closely with our clients to convince them on the merits of more environmentally sustainable solutions,” he said, adding that, in his opinion, he can see the maritime industry being transformed from a traditional and conservative industry into one that is willing to adopt new technologies and innovate.

“While the transformation does not come free of charge and investment is required, we see more and more clients adopting ESG strategies considering the challenges of today’s fast-developing world and emphasis on the environment.”

He concluded: “Digitalisation and decarbonisation are trends of the present and the future, and GMT, as a company, is adapting to the new reality by using solutions to help our clients achieve their strategic objectives.” n