8 minute read

TELEMATICS

GLOBAL SCALE AUTONOMY ON A

IN A CLOSE DIALOGUE WITH A COMMERCIAL VEHICLE MANUFACTURER, HALDEX HAS BEEN SELECTED TO COMMENCE THE CONCEPT PHASE OF AN AUTONOMOUS VEHICLE BRAKING SOLUTION.

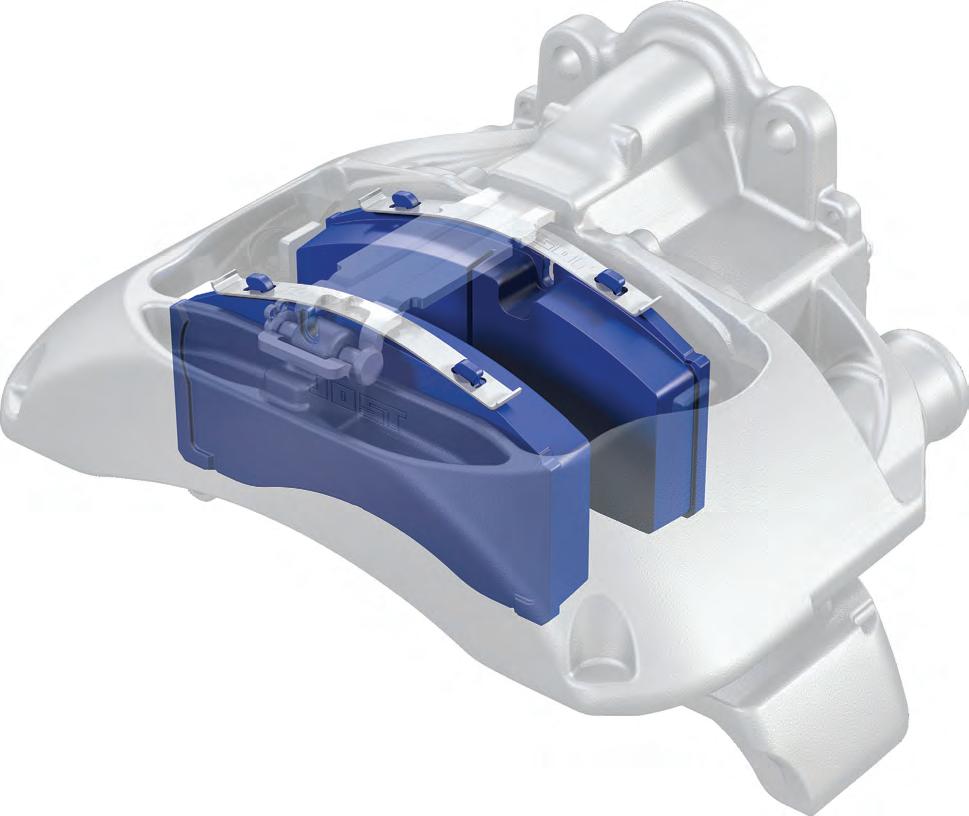

Swedish braking technology company, Haldex, is set to lead a development contract of its ‘Scalable Brake System’ by the end of this year.

With the advent of autonomous driving, vehicle system architecture is about to be re-written. Currently, the vehicle operator manages the integration of propulsion, braking and steering. To reach full autonomy, Haldex is adamant that the subsystems need to be able to accurately control and communicate for the system to be able to analyse the data and make correct decisions.

System integration, according to Haldex, is the key for autonomous driving to become successful.

System integration requires open communication, according to Andreas Jähnke, SVP R&D at Haldex.

“Today, only selected data of the wheel end performance is shared in the system, even though most of a vehicle’s behavior is determined by the wheel end performance,” he says.

“Haldex wants to change that. We fully believe in open systems where the OEM gets full access to the data from the wheel end.

“By developing the brake systems jointly with OEMs, we re-shape the principles for the vehicle system architecture. We know that new and old technology will live side by side for many years. By separating the software from the hardware, you can use the same software functionality to execute different mechanical tasks, hence you can have a vehicle structure which can run both pneumatic and electromechanical brakes.

“We also want to move away from the principle of the [Electronic Braking System – EBS] being a black box that is the central hub for the intelligence in the brake system. To build a scalable system with maximum control and predictability, more technology and intelligence should be placed at the wheel end,” he says.

One of the new products from Haldex that is based on this concept is the Fast Acting Brake Valve (FABV) – it is a high-performance valve, placed at the wheel end together with an Electronic Control Unit (ECU), that is reported to act ten times faster than conventional modular based systems.

The result, according to Haldex, is 15 per cent less stopping distance, but also the ability to ensure that the vehicle runs in the path it is intended to, with a stability and predictability not seen with other technology that is available today.

“When replacing the driver, you need redundancy on different levels,” Jähnke says. “We are not unique to provide steering by braking, but our wheel end accuracy with the FABV is unique.”

System integration is not limited to the truck and furthermore the performance of the combination of truck and trailer will be directly affected by how the subsystems are working as part of the full vehicle system which includes trucks and trailers, according to Jähnke. “At Haldex we are developing the Scalable Brake System to make it feasible for our partners to optimise the safety and performance of the buses, trucks, trailers and ‘movers’ of tomorrow. www.haldex.com Haldex’s Electromechanical Disc Brake EMB is currently being tested on electric buses with positive results.

T R A I L E R TELEMATICS GOING BEYOND

WABCO IS DRIVING TECHNOLOGICAL ADVANCEMENTS THAT WILL CONTINUE TO ENABLE SMARTER OPERATIONS ACROSS THE COMMERCIAL ROAD TRANSPORT ECOSYSTEM, INCLUDING CONTINUOUS INNOVATION IN TRAILER TELEMATICS, IOT AND CLOUD-BASED SOLUTIONS. R oad transport operations in the global supply chain are hampered by a series of inefficiencies including unnecessary driven mileage, remote workforce dependency, non-optimised loads, unplanned downtime as well as a slew of constraints imposed by virtue of regulatory compliance.

In Europe, for example, over 70 per cent land-based freight is transported by trucks, so it is critical for operators to sustain and improve the performance of today’s global logistics flow, which ultimately protects the bottom line of freight businesses.

As a means of overcoming these challenges that impact the bottom lines of many freight businesses worldwide, WABCO has recently established a new Fleet organisation which together with its existing Trailer Solutions organisation focuses specifically on the needs of transport operators and the ecosystems in which they operate.

WABCO’s Fleet organisation is delivering innovations that improve fuel efficiency, reduce downtime while also providing solutions for regulatory compliance, workforce management and load optimisation via advanced Fleet Management Solutions (FMS), Software as a Service (SaaS) and cloudbased technologies.

The organisation operates from over 45 markets, but extends its reach through an impressive 4,600 independent distribution points and 3100 accredited workshops across 115 countries.

WABCO’s combined Trailer and Fleet solutions expands WABCO’s capabilities in delivering transporters new levels of road transport safety, environmental efficiencies and leaner operations.

The FMS and digital technology suite which WABCO provides for trailers harnesses a holistic portfolio of advanced technologies that increasingly make use of the Internet of Things (IoT) and Big Data to deliver new information and

critical data to operators wherever they may be. This development is part of a greater shift to IoT tech that is used across the transportation sector as a whole to overcome fleet inefficiencies.

WABCO’s FMS and digital technology offering leverages the unique data set generated via Trailer Braking Systems and the associated sensors to provide fleet operators with precise insights that lead the way for improved operational efficiency through data integration and advanced analytics.

The WABCO trailer telematics suite consists of three solutions: • TX-GEO to provide location data of any powered or unpowered asset • TX-TRAILERPULSE to provide trailer EBS & health data. • TX-TRAILERGUARD to provide connection to multiple peripherals and available trailer systems

TX-GEO: is an autonomous tracer that localises a fleet’s trailers and assets. The operator receives location information of the trailers it is tracking and can be used to determine the number of trailers on the road or not in use. It can be fitted for any asset type and features: discrete housing, a long-lasting battery and can be quickly and easily installed with options for custom positioning.

TX-TRAILERPULSE is designed to capture a maximum of data on trailers with limited electronics, such as curtain siders or box trailers. Recently launched in Europe and Australia, this solution is a robust trailer telematics solution which combines real-time track and trace functionality with additional remote

Telematics, cloud-based and IoT technologies for trailers are increasingly at the heart of fleet competitiveness in a rapidly changing world.

trailer health and diagnostic information. The solution, according to WABCO, is the first of its kind, combining both trailer tracking and advanced remote diagnostic in one solution at a price level which allows fleet-wide deployment across all trailer types.

Directly connected to the trailer’s EBS, TX-TRAILERPULSE captures the data and forwards this information to TX

FAST FACT Trailer telematics is reported to be one of the fastest growing branches of Internet of Things (IoT), with subscriptions expected to increase by 16 per cent through to 2023. Technology company, WABCO, provides cloud-connected Trailer Electronic Braking Systems (T-EBS) that feature dedicated portals for each customer segment while also leveraging unique data access.

TRAILERFIT which further processes and visualizes it. This information can be used to assess the technical health of the trailer and can provide, for example, root cause indication and repair hints. Additionally, users can monitor the EBS’ use over a trailer’s lifetime and check critical EBS events. Health and diagnostics insights can be shared easily and securely with workshops and service partners building a digitally connected repair and maintenance chain, creating a direct positive impact on the total uptime of fleet vehicles.

TX-TRAILERGUARD, with its numerous connectivity capabilities, is the natural fit for trailers and transports requiring complex tracking and remote control functionality. In the field of temperature management for instance, TX-TRAILERGUARD connects and integrates seamlessly to most reefer and data logger solutions on the market.

TX-TRAILERGUARD can also interface with cargo security solutions such as OptiLock™: WABCO’s electronic high security locking system for trailers and container doors that is suitable for a range of applications including pharma product and food protection. The connection to TX-TRAILERGUARD delivers new levels of security by enabling office personnel to remotely lock/unlock/arm/ disarm security locks without driver intervention.

In general, WABCO telematics solutions provide transporters with trailer, trucks and driver-related information on one back office platform and is designed to optimise logistical processes thanks to its track and trace capabilities, remote diagnostics which allow fleets to provide immediate support to drivers on the road and reduce downtime by allowing them to schedule preventive maintenance and allows vehicle data can be visible to the dispatcher in the fleet’s existing Enterprise Resource Planning (ERP) system or Fleet Management System (FMS).

WABCO Vice President and Global Fleet Solutions Leader, Philippe

Colpron, says every kilometre driven has a cost attached to it – every fleet wants to optimise its trailer space, reduce potential theft, save on vehicle costs, reduce expensive and unexpected downtime, ensure regulatory compliance

WABCO TX-TRAILERPULSE unit.

and optimise the use of its remote assets.

“These are the basics that ensure that fleet and transport operators can continue to be profitable and it is these areas in which we will operate, offering one of the widest, most complete portfolios in the sector that combines the strength of both advanced on-board technologies and an ecosystem of automation solutions, with an extensive integrated global service network,” he says. “And as the industry evolves, we are working to stay ahead of change to enable our customers to transition, benefit from and be successful in an ever-changing transportation world.” www.wabco-auto.com

FAST FACT The introduction of WABCO Fleet Solutions anticipates a rapidly changing transport industry where global megatrends such as population growth, the Internet of Things, higher customer expectations and a push towards sustaining a greener world, combined with increasingly demanding customer requirements for flexibility, speed and safety are putting further pressure on supply chains and fleet profitability. As the commercial vehicle industry moves decisively towards increasingly autonomous, connected and electric vehicles to meet these challenges, WABCO’s Fleet Solutions organisation will drive the technological advancement that will continue to enable smarter operations across the commercial road transport ecosystem.