3 minute read

Going full circle on Manchester’s first cylindrical high-rise

from PERIscope 2023 - 1

by PERIUK

Three60, Manchester

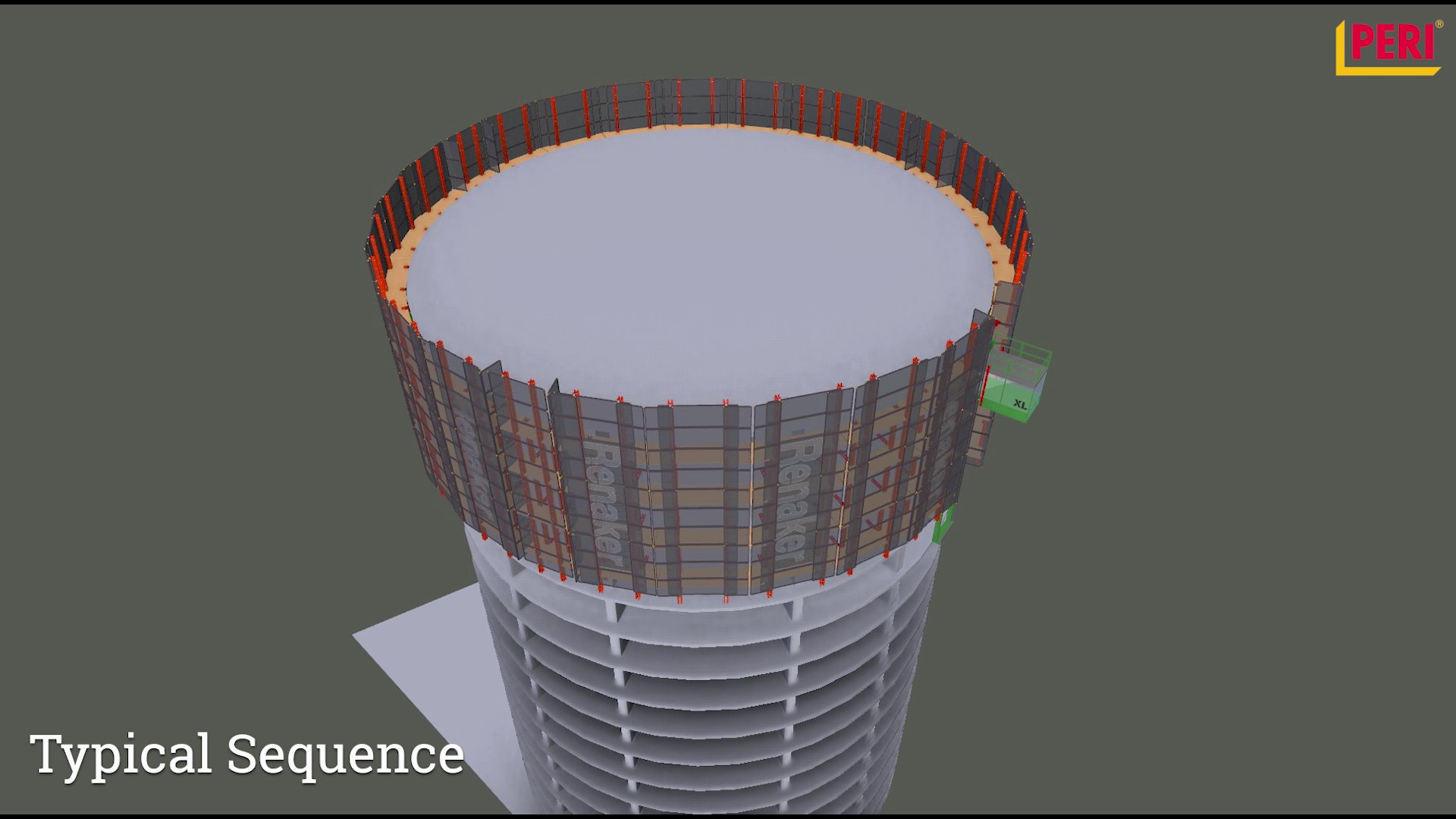

Three60 is one of the newest high rises making its way into Manchester’s skyline. On completion, it will stand 51 storeys tall and comprise over 400 apartments. Renaker is delivering the project as part of the wider Great Jackson Street development scheme.

"By working closely with PERI when we were designing the screens and specifying our exact needs on site, we were able to come to quick and easy solutions."

Constructing at such heights meant there was a requirement to transport material up the building efficiently, as well as the need for perimeter protection to shield the working levels from the wind and leading edges.

Early involvement on the project meant that we could align our temporary works offer with Renaker’s programme seamlessly. This enabled our team to keep up with the construction pace and accommodate the building’s facetted structure.

Protection screens

Our Lightweight Protection Screens (LPS) were installed over four floors. In addition to deflecting wind loads as the building grew in height, the design of these screens had to account for other demands, such as cycle time, access to the slab edge and avoid potential clashes with columns.

We used a double-rail platform screen for this requirement, which offered a working platform between the slab edge and screens. The platforms provided access to prefix bolt boxes for cladding installation.

To accelerate screen installation, we preassembled the masts offsite. Each section was then connected on site with drift pins before being tied to the structure.

The low weight of the screens along with hydraulic lifting saved Renaker time, as the team were able to cycle two screens simultaneously.

Facts

1.5 screens assembled in one day

2 screens cycled in 15 minutes

"The process of cycling the screens was really easy. We could cycle two screens at once, which is a big advantage as it saved us a lot of time and helped us to push the project along."

3D visualisations

When designing the screen solution and slab shoe layout, we had to take the position of the columns around the slab edge into account to avoid clashes.

With the assistance of 3D visualisations, we were able to declash prior to erecting the screens. Having visibility of this information early in the programme meant that the site team could tie the screen design in with other temporary works elements such as the propping and falsework, ensuring all systems worked cooperatively.

XL Hoist

Integrating an efficient transportation system into the programme was crucial as this enabled material and operatives to move quickly between the working levels. As well as providing safe access at height, it enabled the crane to be released for other tasks on site.