6 minute read

Wheat Marketing Center

SERVING THE U.S. WHEAT INDUSTRY

Advertisement

Innovation Lab including Cracker & Biscuit Line, Asian Noodle Line, and Tortilla Line

Wheat is one of the top export commodities moving through the Columbia Snake River System. According to 2020 statistics cited by the Pacific Northwest Waterways Association, 60 percent of all U.S. wheat exports moves through this system on its way to customers in Asia and Latin America. Overall, U.S. wheat producers export half their crop while certain states, including Oregon, Washington, and Montana, export close to 90 percent of their total production. Of the many organizations involved in this endeavor, the unique role of the Wheat Marketing Center (WMC) is explored in this article.

Wheat Marketing Center (WMC) was created as an independent non-profit research and educational entity to demonstrate the value of wheat quality and to document the relationship between wheat quality and the quality of the many end products produced with wheat and wheat flour. Located in the historic Albers Mill Building on the Willamette River, WMC serves to foster a shared understanding between U.S. wheat growers and their customers both domestic and international.

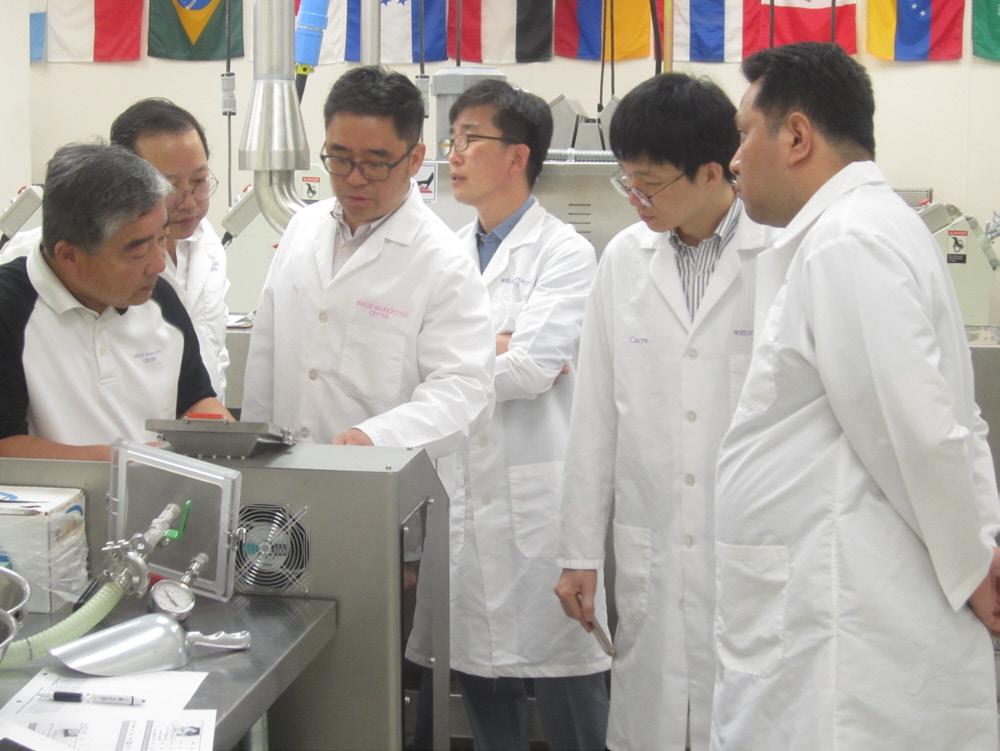

WMC focuses on promoting U.S. wheat by demonstrating its quality and functionality in end products, including Asian noodles, crackers and biscuits, tortillas and flatbread, and a wide range of baked goods and confections. Pilot scale production lines, state-of-theart quality testing equipment, and internationally recognized technical expertise provide technical analysis and valuable education to state wheat commission partners, wheat industry stakeholders, flour mills, and food manufacturers around the world.

BACKGROUND

During the 1980’s, wheat producers sending their wheat to export markets through PNW ports, envisioned creating a research and technical center to increase understanding and knowledge about the quality and value of U.S. wheat. Thanks to the leadership of U.S. Senator Mark Hatfield of Oregon, Congress allocated $6 million to

make the dream a reality. The Albers Mill Building, a former flour and feed mill built in the early twentieth century, was extensively renovated to house the new center. Other wheat-related entities including U.S. Wheat Associates, the Oregon Wheat Commission, and the U.S. Federal Grain Inspection Service (FGIS) have offices in the Albers Mill Building. This co-location facilitates frequent cooperation. In the summer of 1988, the newly formed Wheat Marketing Center hosted a workshop attended by 50 participants, including wheat commission members and staff, customers from Japan, Korea and Taiwan, government officials, and other representatives from the wheat industry. This workshop helped design WMC’s programs and set its priorities.

BOARD OF DIRECTORS

The Wheat Marketing Center Board of Directors is comprised of representatives from the eight member state wheat commissions (Idaho, Oregon, Washington, Colorado, Montana, Nebraska, North Dakota, and Oklahoma), Port of Portland, and five wheatrelated industries. The Board is responsible for setting WMC policy and priorities and through its committees which meet regularly, ensures that the programs continue to provide value for the U.S. wheat industry and its customers.

STAFF

Given the WMC’s technical focus, most of the team are cereal and food scientists with expertise in milling, baking, and product development. Rounding out the team are Executive Director and Office Administrator.

(from left to right) Liman Liu, Assistant Operations Manager; Kin Wong, Laboratory Assistant; Andrew Mense, Food Scientist; Jayne Bock, Technical Director; Mike Moran, Executive Director, Brent Haugen, Office Administrator; Bon Lee, Operations Manager

FUNDING

The Wheat Marketing Center receives about 70 percent of its funding from eight state wheat commissions. Each year, these states allocate funding for general operations, grower workshops, crop quality testing, special projects, and new lab equipment. Other operating income is generated by technical course fees, research projects, and lab testing services. Tailored to the unique needs of each group, WMC provides services to a diverse group of customers including international teams of bakers, mill operators, importers, American firms, state wheat commissions and US Wheat Associates. demands of global consumers. New training programs, state-ofthe-art equipment, and innovative research topics are utilized to meet the ever-evolving challenges facing the wheat industry. Today WMC programs include -

EDUCATION:

• Technical training for customers on improving end product quality (#1) • Grower workshops focused on the importance of wheat quality

RESEARCH:

• Innovative research and product development to meet the market’s challenges and opportunities (#2)

MAJOR PROGRAMS WITH EXAMPLES

WMC remains focused on its core mission of improving the understanding of how U.S. wheat can meet the changing

ANALYTICAL SERVICES:

• Testing and reporting the quality of each PNW crop (#3) • Lab services projects for private customers (#4)

Based on annual requests from U.S. Wheat Associates foreign offices, WMC puts together training courses that meet the specific customer and market needs. For example, in 2022 the US Wheat Associates Seoul office is bringing three groups of South Korean customers for specialized work in: • New flour blends for ramen noodles (to increase U.S. wheat in a sector dominated by Australia)

• Bakery products (attendees will include Korean master bakers)

• Contracting for Wheat Value (helping customers understand how to get the wheat they want)

2 ) TECHNICAL RESEARCH

The technical team, headed by Dr. Jayne Bock, conducts many public and private research projects each year. Research topics are developed in response to market conditions and stakeholder requests. After meeting with several Philippine flour mills, Dr. Bock noticed a recurring interest in alternatives to chlorinated cake flour, driven by increasing consumer demand for clean labeling.

Dr. Bock proposed a project to the PNW state wheat commissions for funding and proceeded to test various options. Results were shared with the USW office in Manila, which in turn made the report available to the mills.

WMC, USW and the state commissions coordinate their efforts to provide crop information, technical support and training to the Philippines and other markets for PNW soft white wheat.

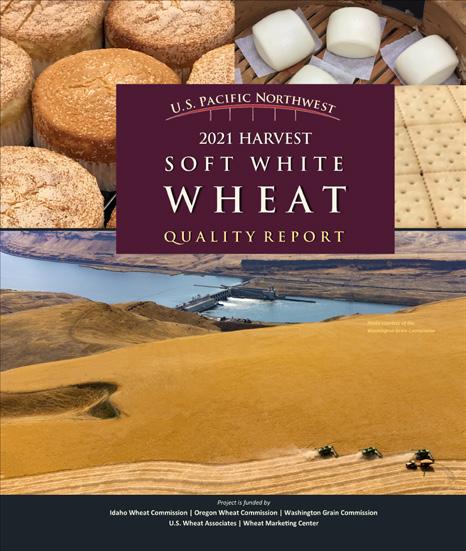

3 ) CROP QUALITY TESTING AND ANALYSIS.

Customers are keenly interested in how the wheat crop is developing each year. WMC provides analytical services each year as wheat is harvested to provide crop quality information to both international markets and state wheat commissions and their grower members. USW and the states host tours and webinars early in the crop cycle to share information about planted acreage and weather. Once harvest starts, WMC receives hundreds of samples from all three PNW states and issues weekly reports on quality by location.

After harvest is complete, USW publishes a national report covering all six wheat classes. WMC provides the data on Soft White and Hard White Wheat.

WMC publishes a separate more detailed report on PNW Soft White Wheat quality. All reports can be found on the WMC website.

4 ) PROPRIETARY ANALYTICAL SERVICES

WMC Lab Services, Inc., the for-profit subsidiary, was created to provide testing services to companies on a proprietary basis. Several wheat importers send samples from their vessels so that they have more information about the arriving wheat.

International and domestic companies contract for help with ingredients or new products.

WMC Lab Services offers a range of services, from individual testing to full-scale proprietary research.

Contact:

For more information on how Wheat Marketing Center can help you and your clients with wheat and grain testing, analysis, and product development visit the Wheat Marketing Center website at www.wmcinc.org or contact Brent Haugen at 503-295-0823.