7 minute read

Planning ahead

Disruptions are a constant new normal for supply chains, say Patrick Long and Michael Wohlfarth, Opportune LLP, USA. Here’s why it’s critical to plan and focus on digital transformation to prepare your organisation.

ipelines play an integral role in the overall supply chain for oil and refined products. The nation’s more than 2.6 million miles of pipelines offer an economic and dependable mode of transportation that’s used pervasively today. How reliable are supply chains? Looking at the headlines in a post-COVID-19 world shows us that you can no longer take any aspect of your supply chain for granted. Disruptions are sure to abound. You need to be prepared for them.

Planned disruptions – learning from the past The first category of supply chain disruptions is those that are planned (or they are at least known with some warning). Life along the Gulf Coast and East Coast means hurricanes from early summer through November. You can count on some disruption based on models. The National Oceanic and Atmospheric Administration (NOAA) put out a headline that reads: ’NOAA predicts above-normal 2022 Atlantic Hurricane Season’. This is the seventh consecutive season that has higher-than-normal chances for more active hurricanes.

What does this headline portend for the upcoming hurricane season? Based on the research, there’ll be between six to 10 hurricanes and between three to six major ones. Having lived through Tropical Storm Allison and Hurricane Harvey, the intensity of the storm doesn’t always dictate the amount of destruction that it will wreak. Major hurricanes in the future are likely to cause more damage. However, tropical storms can also be just as, if not more, destructive.

Patterns of demand – prepare for supply chain weaknesses So, how does this relate to oil and refined products? Patterns from the past can help prepare companies to deal with the inevitable disruptions from future storms. While no one plans for the exact timing of a hurricane, you can bet on there being disruptive storms based on the models. And, when a hurricane heads towards the Gulf of Mexico the focus starts to become the ‘cone of uncertainty’. The ‘cone of uncertainty’ is the forecasted path of the storm. As it nears shore and more data is known, the cone narrows and the path becomes more definite. Since hurricanes are slow-moving forces of nature, there tends to be some time that individuals and organisations can be prepared. For those that will evacuate, it’s critical to pack up and get moving ahead of the rush of traffic seeking to top off their tanks with gasoline and diesel. For those that choose to remain behind and ride it out, there are trips to fill gas and diesel for generators.

When individuals start to react, they generate a surge in demand for fuel and hurricane supplies. Aggregated together, these activities create a spike in demand that’s different than normal activity. Downstream trading companies rely on forecasted demand to determine how much fuel to either produce (in the case of a refiner) or how much fuel to move into a region (in the case of a wholesaler) to keep terminals and downstream gas stations supplied. If companies can recognise this spike in demand early enough, they can be ready all along the value chain to ensure that consumers aren’t faced with an empty pump.

Run-outs aren’t always avoidable Despite the algorithms that abound and the tremendous amounts of planning, run-outs of refined products like gasoline and diesel do occasionally happen. Depending on the intensity of a particular hurricane or tropical storm, rigs in the

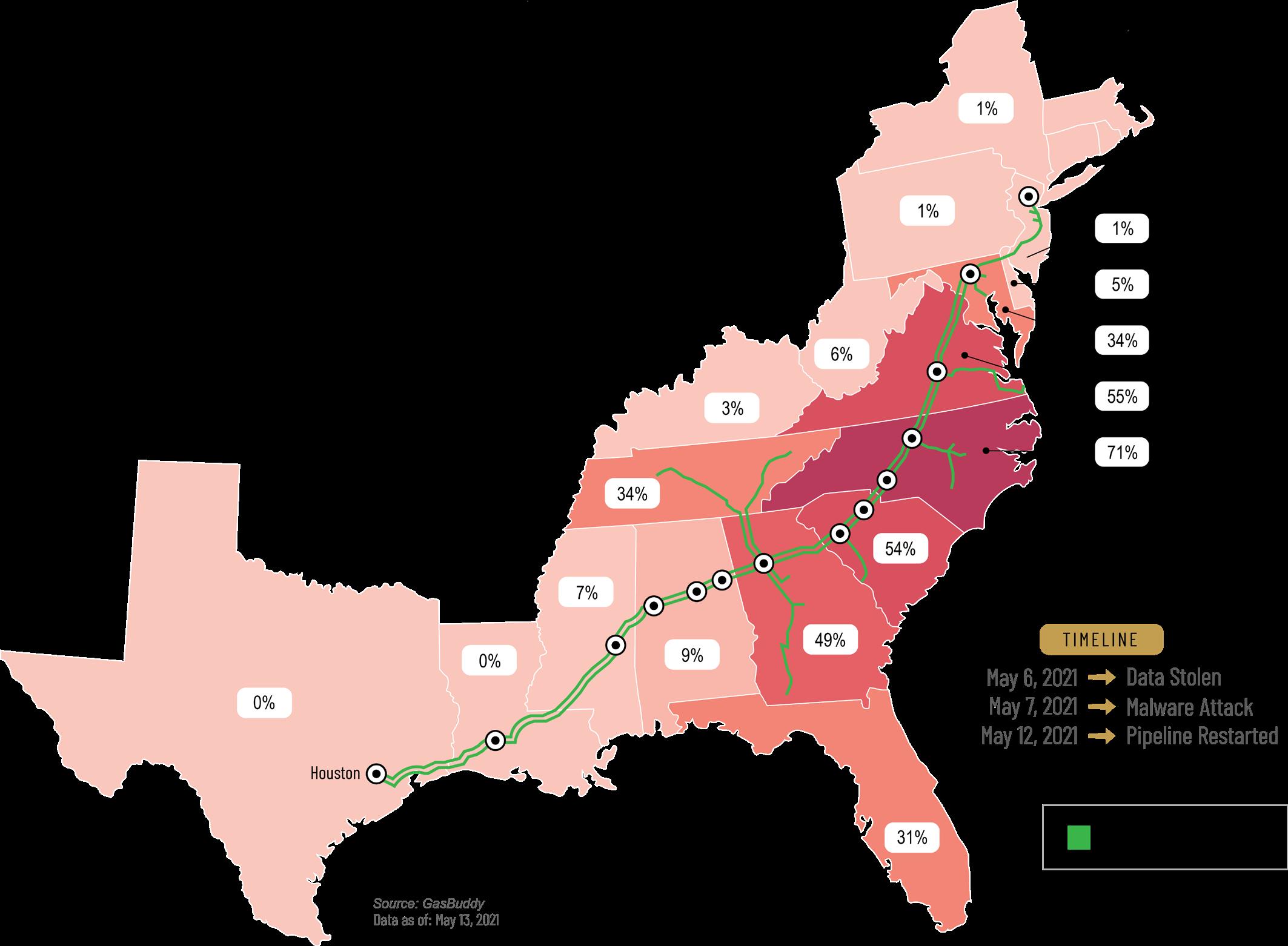

Figure 1. Percentage of stations without gas as a result of the 2021 hacking of the Colonial Pipeline. (Source: Michael Wohlfarth, Opportune LLP)

Gulf of Mexico will be shut-in and crews evacuated. Ceasing production of oil in the Gulf of Mexico reduces the available supply of crude being pumped to refineries onshore. While not a short-term issue, given the aftermath and destruction, the effects could take their toll on reduced crude and, therefore, reduced refined products like gasoline and diesel.

If the storm is intense, then pipelines could also shut-in operations for safety reasons. A pipeline disruption causes inevitable supply chain issues at destinations. There is only a fixed quantity of fuel stored at major terminals off pipelines like the Colonial Pipeline, which runs from the Gulf Coast up the East Coast to New Jersey. When news travels and concentrated populations rush to fuel their tanks, cities that aren’t located along the Gulf Coast can be caught unaware. These spikes (though predictable with 20/20 hindsight) result in headlines in local newspapers. Atlanta is usually one of the first major cities to experience temporary shortages. This is then followed by North Carolina and other cities up the East Coast, pending the storm’s path and the commensurate path of the panicked demand.

Unplanned disruptions – learn to recognise your blind spots Many energy companies rely quite heavily on pipelines as a part of their supply chain. And, thankfully, this mode of transportation offers a high degree of dependability. However, without knowing and planning, this comfort level can become a ‘blind spot’ for an organisation. Completely unplanned disruptions in the supply chain are the second category of disruption.

Take the hacking of Colonial Pipeline as a prime example. That news took the entire country (and the world) by surprise. It immediately created a situation of extreme panic in the localised populations. Was there any rational truth to the spike in demand? No. Consumers weren’t going to drive more in the upcoming week. Companies weren’t going to ship more products in the upcoming days. However, what happened with the shock of the news was that individuals acted in their self-interest. It was a sudden shock that was amplified by news coverage. When rumors started that gas stations were going to run out, panic ensued. The result created a self-fulfilling prophecy that caused run-outs.

Stories proliferated on the news of people filling any container they had with gasoline. The US Consumer Product Safety Commission sent out a tweet urging people not to use plastic bags with gasoline. All rational thinking seemed to evaporate overnight.

Figure 1 shows the Colonial Pipeline and the impact of the shock. Note that not all states reacted the same way. Those in the South seemed to have a larger knee-jerk reaction and, therefore, spiked demand greater than those in the North. The important takeaway is to understand your potential vulnerability and learn from it. If there are more likely to be wild swings in one part of the country, it’s

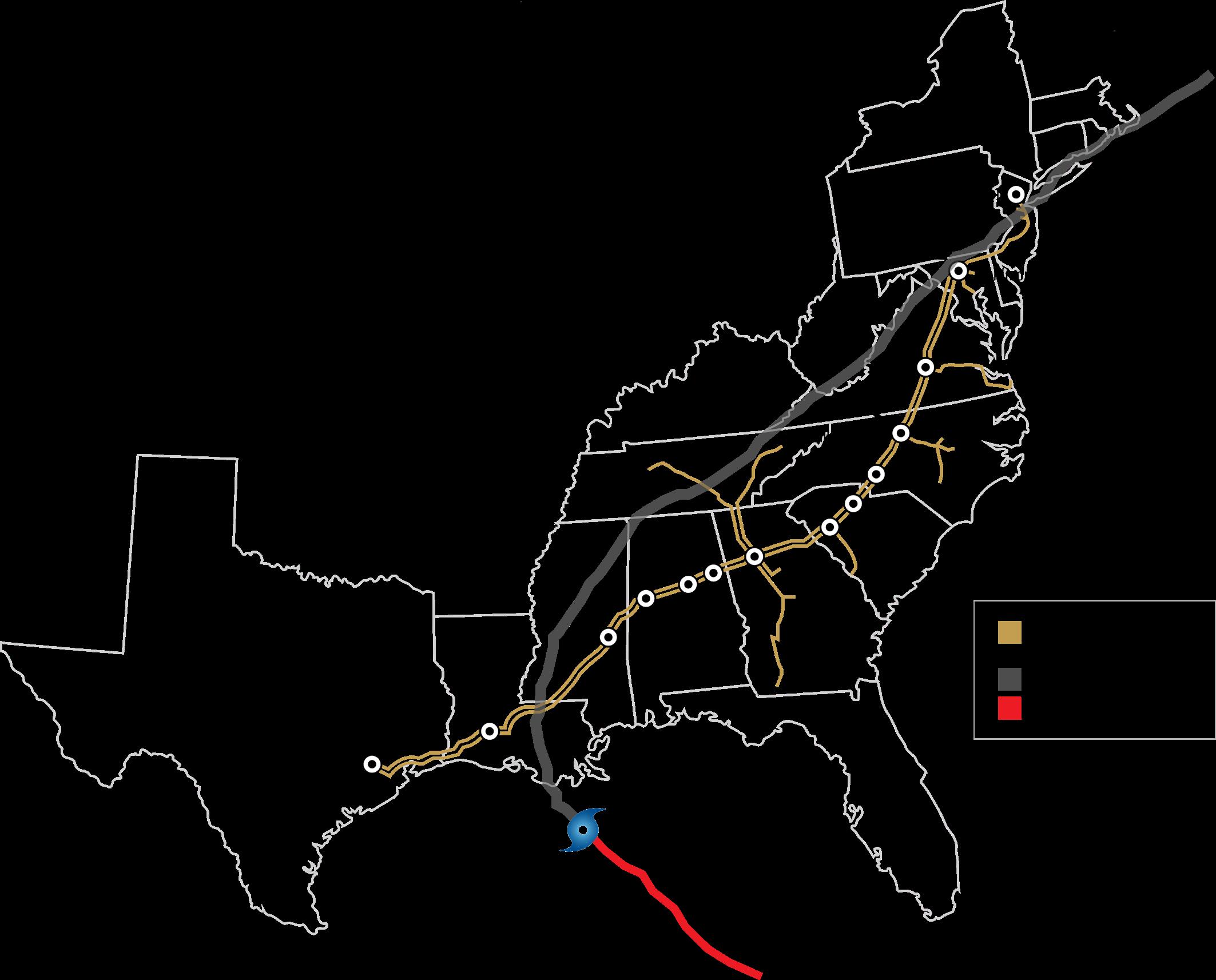

Figure 2. Hurricane Ida storm path that follows closely along the Colonial Pipeline. (Source: Michael Wohlfarth, Opportune LLP)

imperative to have contingency plans in place for the supply of fuel should there be an unplanned outage.

Knowledge is power Planned and unplanned disruptions are a constant and the new normal in supply chains. At some point, there’ll be an abnormal spike in demand. Therefore, companies can plan accordingly. The first step is to digitise your supply chain. Ensure you have accurate tracking of inventory and logistical movements. Then, combine analytics on top of the data. Specifically, bring in weather data in such a way that you can utilise the forecasts to track the disruptions and anticipate them ahead of time.

In Figure 2, the weather data has been combined and overlaid on top of the Colonial Pipeline. The track of the hurricane is plotted along with key areas for terminals. The powerful combination allows you to know where to anticipate low inventory levels due to the spike in demand ahead of a storm. And, given advanced warning, most importantly, companies can act early to avert such issues. Getting started and being prepared Weather disruptions can affect supply chains, but there are ways to prepare for them. Opportune has the deep energy industry expertise and unique technical and business skills to help layer in solutions so that an organisation can increase its overall capabilities and not feel vulnerable to Mother Nature’s elements. Our subject matter experts can evaluate critical assets within your supply chain and implement analytics to provide the necessary visibility and insight into critical components: inventory and logistics being two of the most important.

Then, our experts can work with your organisation to implement a fit-for-purpose optimisation engine. It doesn’t need to feel daunting. Gone are the days of needing to hire a multitude of PhDs or quants for the sole purpose of implementing an optimisation tool. We’ll either guide a packaged solution implementation or customise one that fits your specific needs – no matter how complex.

It’s never too late to start. With the hurricane season underway, it’s imperative to act now and evaluate the overall health of your organisation’s energy supply chain.