10 minute read

Deal-making for the energy transition

STATS Group provide a wide range of industry leading pipeline isolation plugs and line stopping equipment, and with their vast experience can assist operators in assessing the optimum solution for their pipeline isolation, hot tapping and line stopping challenges. Temporary pipeline isolation and intervention can be undertaken safely and efficiently on piggable or unpiggable pipelines or pipework systems.

Pipeline isolation and line stopping can be undertaken in any pipeline medium with appropriate material selection and testing. STATS has experience of isolating hydrocarbon liquid and gases, steam and high pressure liquid CO2 pipelines. STATS' extensive global track record of temporary pipeline isolation covers onshore, topsides and subsea pipelines, from ¾ in. to 54 in.

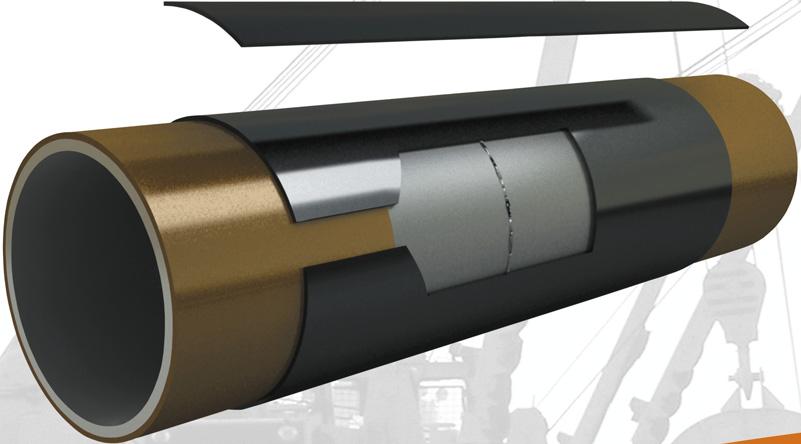

Non-intrusive inline isolation is provided by the Tecno Plug® which is pigged through the pipeline to the required isolation location from a pig launcher or receiver. Piggable isolation tools require no welding or cutting into live lines, leaving no residual fittings or hardware on the pipeline. Once at the desired location the Tecno Plug is controlled remotely using an extremely low frequency (ELF) inductive system for reliable tracking and accurate positioning of the plug. The Tecno Plug is hydraulically activated engaging taper locks which grip the pipe wall and radially expand dual elastomer leak-tight seals. The dual seal design provides a zero-energy zone to enable breaking of containment activities to be conducted safely and efficiently.

STATS BISEP® provides industry-first, leak-tight double block and bleed isolation technology for temporary line plugging, offering a leak-tight seal every time. The BISEP offers significant safety advantages over traditional line stop technologies and can be deployed through a single hot tap intervention while production is maintained through an integrated bypass, avoiding interruption to production and reducing costs, without compromising safety.

STATS Tecno Plug and BISEP are fully certified by DNV GL to verify that the design criteria satisfies the requirements for Pipeline Isolation Plugs to provide dual seal and isolation in accordance with Offshore Standards; DNVOS-F101 (Submarine Pipeline Systems) and recommended Practices; DNV-RP-F113 (Subsea Pipeline Repair) and in compliance with the following code; ASME BPVC Section VIII, Division 2.

The SureTap® range of proprietary hot tapping machines provide performance and reliability for critical, high pressure tapping operations. Designed and built to incorporate industry leading features, the SureTap range incorporates a double block and bleed sealing configuration allowing taps to be performed safely on a wide range of pipeline materials and mediums, including use with sour (H2S) products.

STATS operate across the globe, with services that extend over the entire lifecycle of hydrocarbon assets, from construction, maintenance, extending the life of assets, through to decommissioning and on to hydrogen transportation, carbon capture and storage. STATS' aim is to drive higher levels of safety to support the industry in the transition to a low carbon future.

Projects

F Interior Gas Upgrade in interior British Columbia, supplying 42 separate BISEP isolations from 6 in. to 10 in. over a 3 month period as part of customer’s non-piggable to piggable pipeline upgrade, full supply including in-service welding.

F Remote Tecno Plug pigged 116 km to isolate a 24 in. pipeline to facilitate a pipe abandonment and replacement project in Northern Alberta, Canada.

F Subsea mechanical clamp and hot tapping services provided for a global engineering and construction company in the Bass Strait, offshore Australia. The 18 in. clamp incorporated a 12 in. offtake to provide a tie-in point to allow a new gas field to be brought online and fed into the existing 18 in. gas pipeline. The new tie-in has helped curb the potential shortfalls predicted for

Australia’s southern and eastern states.

F STATS supplied a 20 in. Remote Tecno Plug to provide pipeline isolation services on a Normally Unattended

Installation (NUI) in the Southern North Sea as part of an export pipeline maintenance campaign for a major

UK Oil and Gas Operator. Due to limited temporary accommodation, once the plug had been deployed to the set location and seal verification testing was completed, continual monitoring of the isolation was carried out remotely via satellite link from our headquarters in Aberdeenshire.

F STATS provided isolation and reinstatement leaktesting of a 38 in. sour gas export pipeline in Qatar. Two type approved Remote Tecno Plugs provided a fully monitored leak-tight isolation, which facilitated the safe hot work modification of 2 in. bypass pipework around the 38 in. ESDV.

18 in. class 900 subsea mechanical clamp with class 1500 12 in. branch, valve and SureTap hot tap machine. ONSHORE PIPELINES

OFFSHORE PIPELINES

TURNKEY TURNKEY CONSTRUCTION CONSTRUCTION

HORIZONTAL HORIZONTAL DIRECTIONAL DIRECTIONAL DRILLING DRILLING

COMPRESSOR COMPRESSOR STATIONS STATIONS

WELDING WELDING

FINANCE, FINANCE, STRATEGY STRATEGY &ANALYSIS & ANALYSIS

FEASIBILITY FEASIBILITY STUDIES STUDIES

TERMINALS

RESEARCH & RESEARCH & DEVELOPMENT DEVELOPMENT

MAINTENANCE

REHAB

ONSHORE PIPELINES

OFFSHORE PIPELINES

TURNKEY TURNKEY CONSTRUCTION CONSTRUCTION

HORIZONTAL HORIZONTAL DIRECTIONAL DIRECTIONAL DRILLING DRILLING

COMPRESSOR COMPRESSOR STATIONS STATIONS

WELDING

FINANCE, FINANCE, STRATEGY STRATEGY &ANALYSIS & ANALYSIS

FEASIBILITY FEASIBILITY STUDIES STUDIES

TERMINALS TERMINALS

RESEARCH & RESEARCH & DEVELOPMENT DEVELOPMENT

MAINTENANCE MAINTENANCE F or more than a century, T.D. Williamson (TDW) has partnered with the oil and gas industry to deliver energy to an ever-changing world. Our innovative solutions maximise uptime, improve throughput, avoid shutdown and minimise risk to pipelines, people and the environment. We serve the gathering, transmission and distribution sectors of the pipeline industry with a global portfolio of products and services for both onshore and offshore applications.

Services

Intervention and isolation

TDW provides advanced isolation and hot tapping and plugging equipment that meets the highest performance standards, including hot tapping machines, fittings, valves and plugging heads. The STOPPLE® Train isolation system allows two independent plugging heads to be inserted through a single fitting. In its typical configuration, the nonintrusive SmartPlug® system meets the criteria for a true double block isolation. It can be used onshore or offshore.

Integrated pigging, system components and pigging services

We’ve designed and manufactured our extensive selection to meet specific applications and pipeline sizes. Components include pig tracking, pig signaling and closures. Our D2000 quick-actuating closure combines safety and ease of operation for any pigging operation. We also provide consulting, pre-commissioning preparation, pipeline cleaning, project management and stuck pig response.

Integrity assessment

STOPPLE® Train isolation system.

EMAT 10 in. tool. By providing end-to-end integrity solutions – from assurance-based cleaning to inline inspection runs to actionable inspection results – TDW keeps your system running safely and productively, helps you prioritise repairs and ensures regulatory compliance.

Projects

F To make a large-diameter pipeline system piggable for inline inspection, TDW performed a STOPPLE® operation with two pieces of equipment weighing nearly 10 t combined. The job required a 65 t crane to lift and lower the

STOPPLE equipment. Coupons cut from the pipeline weighed 75 lb each. For more than 60 years, TDW STOPPLE® plugging machines have represented the safest and most reliable solutions for isolating pressurised sections of pipeline without shutdown or interruption of service.

F TDW performed progressive cleaning to clear a segment of an 8 in. crude gathering pipeline in

Mexico and restore service to stations for delivery.

Using increasingly aggressive pigs, TDW removed 1.8 t of sediment that had reduced the interior diameter of a 10.4 km (6.46 mile) section to 4 in.

The bore restriction prevented the operator from transporting and delivering oil downstream. The progressive cleaning program included seven pigs plus DEF and other inline inspection technology.

F Using the TDW Multiple Dataset (MDS) tool, which offers comprehensive mechanical damage assessment by leveraging multiple technologies on a single inspection platform, technicians completed a 24 in. ILI run on a crude transmission line in the Canadian Rockies. The tool climbed climb 1243 m above sea level and then made a steep descent. In order to maintain the necessary speed and ensure success, the XYZ run required advance flow and pressure application.

ONSHORE PIPELINES

OFFSHORE PIPELINES

TURNKEY TURNKEY CONSTRUCTION CONSTRUCTION

HORIZONTAL DIRECTIONAL DRILLING

COMPRESSOR COMPRESSOR STATIONS STATIONS

WELDING WELDING

FINANCE, FINANCE, STRATEGY STRATEGY &ANALYSIS & ANALYSIS

FEASIBILITY FEASIBILITY STUDIES STUDIES

TERMINALS TERMINALS

RESEARCH & RESEARCH & DEVELOPMENT DEVELOPMENT

MAINTENANCE F ormore than 90 years, the Winn & Coales International Group of companies have been creating bespoke and off-the-shelf solutions that provide enduring protection against corrosion and chemical attack to buried and exposed pipes, valves, fittings, steelwork, marine structures, tanks and concrete bunded areas.

In May 2021, Winn & Coales International expanded their product portfolio with the acquisition of the global ViscotaqTM business including Amcorr Products & Services Inc, manufacturer of viscoelastic protective coatings. The acquisition of Amcorr is aligned with the Company’s focus on investing in and providing the highest quality corrosion prevention solutions for their customers.

With seven subsidiaries worldwide, the company can draw upon a wealth of experience in producing its well-known brands; DensoTM, PremierTM, Viscotaq ProtalTM , Premier Shrink SleevesTM, ArchcoTM, SteelcoatTM BoreWrapTM and SeaShieldTM .

One of the latest innovations of the Company is Denso Bore-Wrap, a superior, heavy-duty, sacrificial Abrasion Resistant Outerwrap (ARO) for trenchless pipeline installations, severe handling, or installations in difficult terrain.

Projects:

DENSO USA LP – DENSO BORE-WRAP

Denso Protal 7200 and Denso Bore-Wrap were recently used to protect the field joints of a new 18 in. crude oil pipeline in Houston, Texas. The pipeline was installed by means of Horizontal Directional Drilling (HDD). During the four-day installation process, one of the pipe rollers couldn’t handle the load while lifting and forced the pipe over the edge of the roller. While this does happen occasionally, it typically causes damage to the anti-corrosion coating and it can gouge the steel pipe which requires a cut out or repair.

In this instance it happened to occur as the field joint wrapped with Denso’s sacrificial outerwrap was just above the roller. When the pipe dropped, the Denso Bore-Wrap took the initial impact from hitting the bearing, and as the load continued to roll, the bearing housing broke. On inspection, the contractor found that the point of impact and the gouge from the point of the bearing breakage had failed to penetrate the Denso Bore-Wrap and none of the underlying field joint coating was damaged. The contractor was able to again lift the pipe and proceed with the installation as planned without any further repair or mitigation needed.

Upon completion of the installation, the first joint of pipe was pulled out and inspected. Denso Bore-Wrap had protected the coating on the joint and exited the bore hole with very little sign of wear. The circumstances of this HDD pull showcased the products performance in terms of impact, gouge, abrasion, and flexibility, and the results speak for themselves.

Field joints protected with Denso Bore-Wrap™ ARO during HDD installation. DENSO NORTH AMERICA (CANADA) – DENSO PROTAL 7200 SPRAY GRADE

The KAPS Pipeline project consists of a 16 in. condensate pipeline and a 12 in. NGL mix pipeline. The KAPS pipeline is currently being constructed from northwest of Grande Prairie Alberta and connect to Keyera's Fort Saskatchewan Fractionation and Storage Facility.

Advance Bending in Calgary Alberta was awarded 1400 cold bends to be coated on the current scope of work. The coating for this project will be completed with approximately 18 000 l of Denso Protal 7200 Spray Grade liquid epoxy coating. The project started in May 2021 and has an estimated completion date of Autumn 2022.

WINN & COALES (DENSO) LTD – INDIAN OFFICE – DENSO PETROLATUM TAPE SYSTEM

Oil India Limited (OIL) is one of the largest public sector hydrocarbon exploration and production companies in India. OIL is presently operating 1860 km of cross-country oil pipeline and owns a 1157 km long x 18 m/14 m wide right-of-way (ROW) from Duliajan, Assam to Barauni, Bihar.

Due to natural degradation of the existing coal tar coating on these pipelines over time, there has been increased demand on the CP system. Moreover, addition of more pipeline in the same ROW has increased the load on the CP system. The Denso Petrolatum Tape System was supplied for the refurbishment of the pipeline and block valves, some of which were in harsh wet, marshy conditions.

PREMIER COATINGS LTD – PREMIER™ BUTYL TAPE SYSTEM

The Baltic Pipe project is an approximately 900 km pipeline constructed for the transmission of natural gas between Denmark and Poland and will enable bidirectional transmission, which means it will also be possible to supply gas from Poland to Denmark. The Premier Butyl Tape System was recently supplied to protect sections of pipe and service pipe from corrosion on the pipeline in Denmark.