12 minute read

Purpose-Built Power Sources

Figure 1. Komatsu's autonomous trucks operate leveraging the FrontRunner system.

Jess Stephen, Komatsu, discusses haul truck power sources that are purpose-built for a sustainable future.

Agrowing sense of urgency now drives equipment planners as they work toward their 2030 emissions reduction targets. In a departure from past development programmes, some original equipment manufacturers (OEMs) offer engagement and collaboration to mining professionals overloaded with many questions, inspirational product developments and new operational challenges, where prolonged machine lives extend the carbon impact of today’s choices out to their corporate 2050 net-zero emissions goals.

Many questions haunt leaders and the planners charged with achieving emission reductions: How are these goals reached? What equipment and operational changes are necessary? What will this cost? How does the mining industry answer those questions?

International expectations help create a clear vision of the long-term future: the technologies are under development, but specifications for practical solutions remain elusive.

And, as one report from McKinsey says: “Within the space of heavy machinery and equipment, there is still a very limited share of battery-electric vehicles (BEVs), even though electric propulsion (with cable) is not uncommon in some equipment.”1

Thankfully, industry innovators are closer than ever to practical prototypes which convert diesel-powered equipment to 100% battery powered. They are also on the verge of what some considered theoretical just a decade or two ago: power-agnostic drive systems that allow individual sites to choose different power sources for their off-highway mining haul trucks, based on the mine’s physical application, environment, and economic needs.

Increasingly optimistic studies reinforce what industry experts are coming to accept: changing to zero-emission mining is not only necessary for the planet, it is also essential for profit.

Moving more material at lower cost

In another recent analysis, a global mining company weighed diesel-based equipment against a fleet powered by alternative energies. It determined that it could remove more than 6 megatons of carbon dioxide (CO2) per year, 20 years earlier than planned – equal to eliminating nearly 1.5 million passenger cars.2

Based on testing and analysis by Komatsu’s Greenhouse Gas (GHG) Alliance and Sustainability for mining, mining companies can move more material at lower cost by switching to electric power for mining equipment. A step-by-step transition of mining haulage delivers incremental returns that drive continued investment through each phase of the journey to zero emissions. These economic benefits remain well after the transition to 100% electric power.

Komatsu has run thousands of simulations with major mining companies and together is finding 5 – 15% cost per tonne reductions across a variety of applications. The analytics teams are not using a bunch of future assumptions – they are evaluating current battery technology, trolley infrastructure, change management, and operational impact. It is still early, but the simulations are very encouraging.

Figure 2. Komatsu’s power agnostic development truck undergoes testing at a Komatsu facility in the US.

Two strategies toward a green transition

But how do companies get from today’s profits with diesel to expanding them with electric?

Getting there requires carefully crafting a unique strategy for each organisation and its needs. There is no one-size-fits-all solution: each organisation and site must carefully investigate, analyse, and develop their plans.

That conclusion is echoed in the fleet study, which found that companies ready to embrace the complexities of the diesel-to-alternative energy transition had a ‘clear competitive advantage’. They may be able to charge a price premium to customers for products that are truly green.2

However, the report adds, first is not always best. Analysts offered two paths toward a green transition: Move quickly away from diesel but pay more upfront; or migrate more gradually to alternative fuel sources, but deal with more complexity.

In an example of a zero-emission transition strategy developed within the Komatsu GHG Alliance using an iterative analytic process, one mine plans on first utilising a truck fleet powered with diesel trolley for increased production, reduced fuel consumption, and lower emissions. Planning for an autonomous haulage solution takes place during this trolley deployment. Once the trolley is integrated into daily operations, then autonomous haul solution (AHS) deployment begins, delivering additional production from fleet optimisation gains. With the AHS trolley in place, the plan calls for strategic replacement of diesel engine power modules with 100% battery power modules at engine rebuild, eventually converting the entire fleet to zero-emissions.

With a plan, companies know where they are going. The investments become self-funding from production improvements and cost savings, and they have a timeline for when they are going to do it. However, this plan is not for everyone and does not work where new licensing and regulatory requirements call for zero-emissions from day one.

Start with people

So, developing customised strategies now can help companies reach their equipment-based net-zero goals into 2030 and beyond. But what are the risks? What about the technological limitations? And what is the upside – beyond going green?

The biggest risk to this mining transition might involve people. With autonomous haulage, the industry has learned that people are the primary limiting factor to deployment.

Any company considering a transition from diesel to electric vehicles and beyond should start looking for personnel long before deploying equipment.

The time to start looking for planners, thought leaders, and drivers of change management – is now. The benefits from recent advancements in workforce diversity show a clear advantage to those organisations willing to make the long-term investments in their people. This broader, more diverse talent pool is crucial to the future success of the transition to zero-emission mining.

These working teams will develop more than an individual organisation’s plan for EV or power-agnostic rollout. They will also help shape industry standards and regulations for everything from battery manufacturing to mining operations, and risk management to shipping.

The real risk to successfully achieving a zero-emission transition lies in not having the right people who create and drive the right plans.

Working together to rapidly innovate

That spirit of collaboration led to Komatsu’s GHG Alliance, which brought together mining leaders from Rio Tinto, BHP, Codelco, and Boliden to work together on product planning, development, testing, and deployment of the next generation of zero-emission mining equipment and infrastructure.3 The goal is to rapidly innovate in support of carbon reduction targets. Komatsu GHG Alliance membership has grown rapidly since its founding.

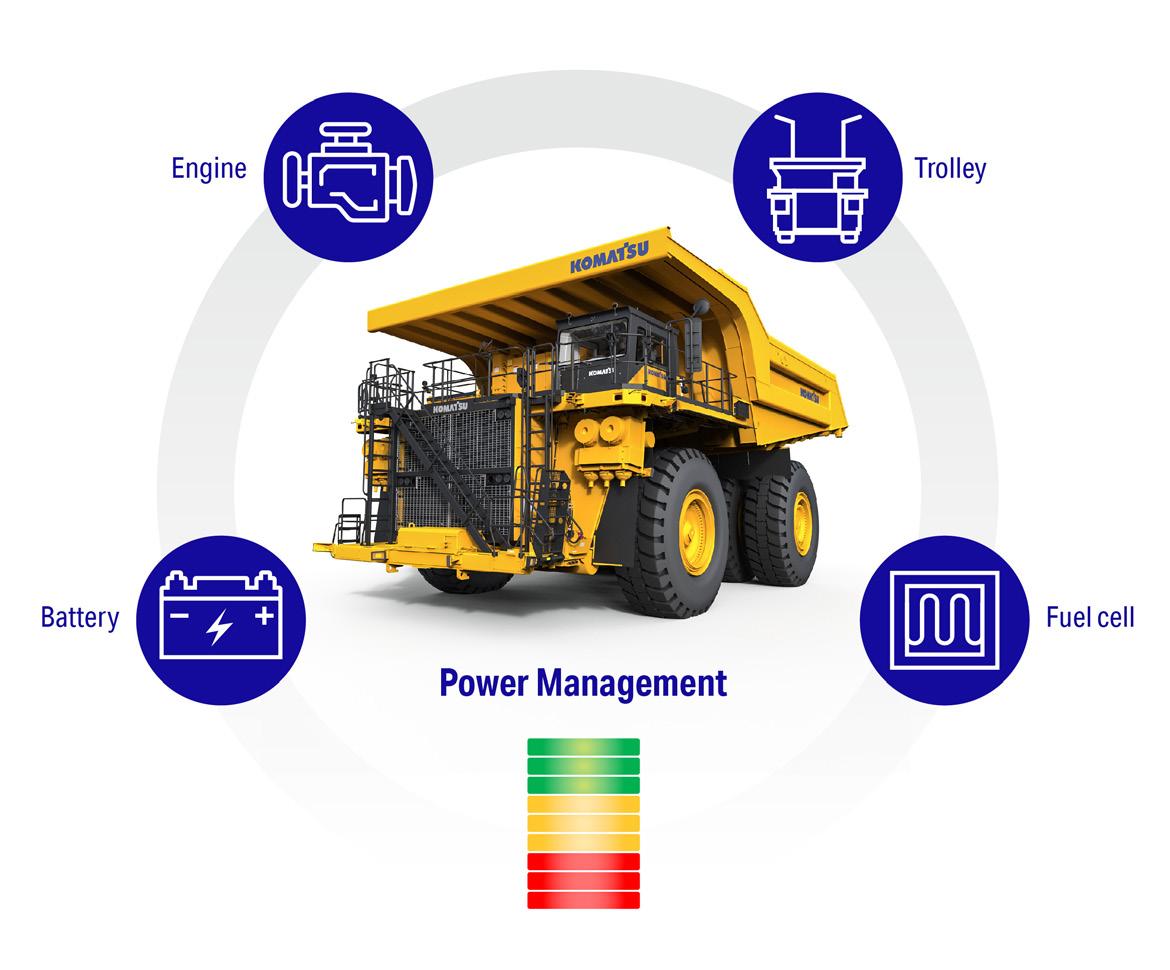

The alliance’s initial aim is to advance Komatsu’s power-agnostic truck concept for a haulage vehicle that can run on a variety of power sources – including diesel electric, electric, trolley (wired), battery power, and even hydrogen fuel cells.

The first step toward that goal should come later in 2022, when Komatsu completes the installation of a trolley line at its Arizona Proving Grounds (AZPG) near Tucson, Arizona. This 1.2 km line establishes the backbone for development of zero-emissions haulage, AHS trolley, and trolley power research. Initially the line will power Komatsu’s EVX, a 100% battery-powered, zero-emission haul truck, currently used for testing and research.

Historically, the company shares very little information about development projects – the industry only hears about the final product release. With these new products, the complexities of the zero-emission transition and dramatic infrastructure changes drive a need for deeper collaboration with equipment stakeholders much earlier in the process. This is the first

Monitor and improve mill performance to reduce total cost of operations performance to reduce total cost of operations

Move to a cost-efficient and predictive maintenance model with a data-driven approach

• Identify key areas for maximizing savings and improvements through connected technologies and services • Predict, plan, and optimize horizontal grinding mill performance • Increase efficiency by reducing the likelihood of failures and reducing both the cost of production and cost of maintenance

time Komatsu has ever collaborated so closely with its customers in so many stages of development.

The innovative approach will give the GHG team insight into the development, testing, and rollout of not only an EVX concept battery test platform – which debuted in September 2021 at MINExpo in Las Vegas – but also the 930E power-agnostic diesel haul truck, which is envisioned as a diesel-powered vehicle that can be fitted for battery-power and future energy options.

Power source flexibility

The concept is based on a ‘plug-and-play’ model: Komatsu will provide space within the power agnostic trucks where the engine module usually fits. Over the long life of the truck, customers can adapt the power module with different power generation and storage solutions that meet their strategic needs. At first, that might mean diesel. Then, in a first or second phase engine rebuild, customers could outfit the power-agnostic haul trucks for battery operations.

Converting from diesel to battery is largely a matter of mechanics. Replacing the diesel engine with battery trolley power reduces the already low number of moving parts on Komatsu equipment, further reducing service costs. Eliminating all those little valves, moving parts and troublesome fluids, such as engine oil, reduces maintenance interventions. Service personnel will not touch the machine as often, which is a huge benefit in TCO modelling. Less time in the shop means more time in the dirt moving tonnes – reduced maintenance time and increased production makes a big difference economically.

Trolley system installation can be cumbersome, but also provides many advantages.

For example, with trolley lines, trucks can charge their batteries while hauling; customers can charge the battery while the truck is moving uphill; and, with the added power available from trolley segments, the batteries are fully charged without interrupting production.

For example, a diesel engine is limited to 2700 hp (2000 kW). With trolley lines, the truck can access up to 6.5 MW, which increases propulsion and charging opportunities. It is efficient, low-cost energy available to the truck’s power management system and drive motors.

Of course, batteries do have some limitations. Unlike car batteries, battery swapping with power-agnostic haul trucks will not likely be an option because of the degree of difficulty and high potential for damage.

Komatsu has looked very seriously at in-circuit battery swapping strategies, but the risk/benefit value is challenging for the large, opencast mining trucks.

Battery technology is a source of optimism for equipment manufacturers where continued innovation, performance, and cost improvements expand the range of economic viability and applications.

Only now is battery technology reaching toward the performance, cost, and durability requirements for the mining industry. Advancements in battery production and packaging make reliable operation possible. Strong manufacturing and global support is the real magic ingredient.

Transitioning profitably to zero-emission mining

This is where Komatsu is counting on its decades of battery research and strong collaboration with GHG Alliance members. Komatsu has been testing battery power for mining trucks since the mid 2000s. Its equipment strategy takes advantage of currently available technology while provisioning for future innovations. This means collaborating closely with customers and understanding their needs and challenges, which is where the company has spent a lot of time. It is working one-on-one with mining customers to better understand: Where are they today? Where do they need to go? What changes need to be made to machines for them to fit the future of mining? Collaboration is critical because it entrusts mutual understanding. This engagement drives successful deployment planning and operation of new technology. Expanding collaboration across the industry will be key for developing standards that will manage the many manufacturing, logistics, and operational questions that will arise with battery powered mining equipment. The takeaway is that GHG Alliance members are helping each other develop the entire power agnostic ecosystem. For their cooperation, alliance members get early access Figure 3. Komatsu’s GHG Alliance is working toward the development of to developments within Komatsu, which could a power agnostic truck concept for a haulage vehicle that can run on a give a competitive advantage as products come variety of power sources. on market.

There is nobody today using fleets of 240 t or 320 t fully-electric battery-operated trucks, and many logistical questions remain. Frankly, there are few standards in place for managing this process. How will the world ship giant battery modules across the ocean? What impact will regional energy or industrial policy decisions have on importing, service, or remanufacturing battery modules? Many things that require input and guidance continue to evolvie rapidly. The company is therefore going to work with its customers closely and approach these opportunities together.

Komatsu meets with GHG Alliance members on a regular cadence for working sessions. This process offers group time for planning and reporting, as well as management of working teams engaged with subject matter experts resolving specific challenges. This effort drives toward preparation for strategy development and power-agnostic fleet deployment.

One of the looming questions for asset managers and emission strategists has been the impact of longer economic life expectancies from trucks, such as the 930E, but this is a question Komatsu cannot answer for everyone.

As a result, this is is why the GHG Alliance team engages in extensive analysis and strategy development, as customers evaluate upcoming fleet replacements and upgrade path to their ultimate 2050 zero-emission targets. The power agnostic truck series will make this transition much easier.

In addition, Komatsu has zero-emission plans for the ‘-5’ truck models currently available today. These projects will use technology derived from the power agnostic development programme.

Conclusion

As discussed in this article, diesel-to-battery transition remains more about people and planning than equipment. Technologically, a profitable transition to zero-emission mining is possible. Practical success depends on people making an early start, collaborating openly, and creating innovation from the challenges of their first planning attempt. Companies should start small, but start. And start now.

References

1. ‘Harnessing momentum for electrification in heavy machinery and equipment’, McKinsey & Company, (2019), www.mckinsey.com/industries/automotive-and-assembly/ our-insights/harnessing-momentum-for-electrification-in-heavymachinery-and-equipment 2. RUSSELL, R., ABEL, M., FERNANDEZ, D., HARWOOD, K., LEACH, M., and MCCABE, G., ‘Net-Zero Trucks? Yes, It’s Possible’, BCG, (2021), www.bcg.com/publications/2021/alternative-fuels-for-trucksfactors-to-consider 3. ‘Komatsu announces collaborative customer alliance to advance zero-emission equipment solutions - New offerings to leverage electrification for next generation’, Komatsu, (2021), www.komatsu.jp/en/newsroom/2021/20210802

INNOVATION Starts with IWT

Innovative is not just in our name. Our engineers thrive on solving tough mining problems, specializing in:

• Reliable Voice and Data Communications • Real-time Personnel & Asset Tracking • Wireless Gas Monitoring • Production & Environmental Sensor Data • Equipment State-of-Health Data • Production and Maintenance Analytics