4 minute read

FUTURE-PROOF PACKAGING

from Schur

Writer: Rachel Carr | Project Manager: Dennis Morales

Schur’s story began 176 years ago in Horsens, Denmark with Johan Wilhelm Schur. Familyfounded and still family-owned, six generations later the company is providing end-to-end packaging solutions through the combination of technology and sustainable materials.

Although still headquartered in its native land, many things have changed since the company’s inception in 1846. Its portfolio has expanded and the technology has advanced, however, its values remain the same.

Schur is an international family of 12 companies operating in six countries including Denmark, Sweden, France, Germany, the US, and finally, Australia.

The latter is the company’s most recent area of growth with 150 employees. Through its expansive client base, Schur has a global reach.

The company supplies solutions to a variety of industries from fastmoving consumer goods (FMCG) to B2B tools and DIY, to the health and medical industry.

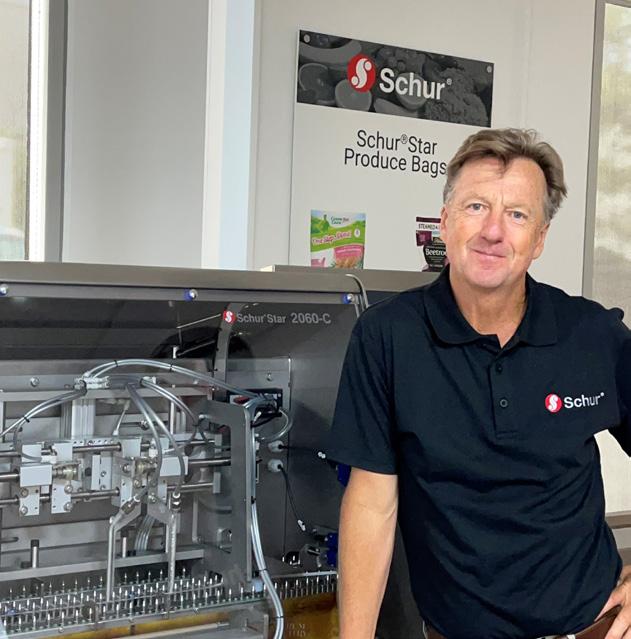

“We are founded on Danish values but with a global footprint and local presence and production,” establishes Paul Quinn, CEO of Schur Star Systems Australia Pty Ltd.

Quinn was drawn to his position at the company with good reason, since Schur’s family values are aligned closely with his own.

“Due to its considerable history, Schur takes a measured long-term approach to business and continues to invest in and support the company in Australia. I am convinced we have a great future and am extremely grateful for the opportunity.”

Sustainable Solutions And Strategies

Sustainability is at the core of Schur, and with its wealth of experience and knowledge, the company is able to offer responsible packaging solutions.

“We always strive to find the best possible solution for the environment, while at the same time also ensuring that we provide the properties necessary to protect the specific product, based on the needs of our customers,” Quinn tells us proudly.

The company is ecologically aware and wants to leave a positive imprint, and a legacy to be proud of. Quinn informs us that decency and integrity run through Schur’s DNA and define everything the business accomplishes.

“As a member of the Australian Packaging Covenant Organisation (APCO), we are working towards 2024 packaging and recycling targets which will provide better solutions for our customers and consumers in Australia.”

It is clear that sustainability is central to the way Schur does business. By continually moving towards the most sustainable solution while maintaining the requirements for product protection, it advances Schur ahead of the pack.

“In a world where packaging is seen as a problem, we are committed to making packaging part of the solution. We are currently in the process of developing our sustainability strategy towards 2030. Our vision for the future is based on a systematic approach to circular sustainability via end-to-end packaging systems,” states Quinn.

Leader Of The Pack

One of Schur’s legacies is innovation, which has played a crucial role in where the company is today. Revolutions in packaging and modern production facilities maintain a competitive advantage and this progressive outlook is evident throughout Schur’s history.

“From developing an innovative method back in the 1890s for printing on wood, and winning an award at the 1983 World Expo in Chicago, to building one of the most modern and automated production facilities at our factory in Gallin, Germany, in 2016, to continuous innovation in packaging development such as sustainable films for our roll stock business in Australia – innovation is part of our DNA and how we work with customers to continuously explore new paths to create the best solutions together,” shares Quinn.

Fast forward to today, and in addition to packaging materials, Schur can supply turnkey packaging solutions based around the latest Schur® Star unique technology. It is a combination of premade bags and a versatile packaging machine that matches any product, packing process, segment, or market requirement.

Esko

The latest Esko software makes it easier to automate, connect and accelerate to overcome today’s packaging business challenges.

With today’s brands and packaging suppliers facing a catalog of potentially crippling challenges, Esko develops its software innovations specifically to make it easier for people and processes to connect, to automate operations and to drive operational improvements.

“From the energy crisis and the erosion of margins to material shortages and labour and skills deficits, we know there are many significant challenges for businesses today,” said Scott Thompson, Esko Marketing and Channels Manager, Oceania. “The role of technology and innovation is key in surmounting these. It’s now imperative that companies review their current business operations and identify areas where they can make meaningful improvements and drive operational efficiencies in order that they not only survive but thrive.”

It is in this climate that Esko developed its latest software version, bringing to market new technological developments that will advance the industry, helping businesses form a foundation to identify waste, mitigate risk and optimise opportunity while preparing for the predicted megatrends of 2023.

The latest Esko software release includes a host of new features, including:

• Dynamic subscriptions

• ArtPro+ GMG OpenColor Connector

• Greater flexo automation

• Automated workflow improvements

• New FEFCO standards as parametric tools in ArtiosCAD

• Integrated Tilia Labs Artificial Intelligence

“Our key focus is to deliver technology that makes it easier for packaging companies to connect its people and processes, to access data, automate operations and to drive operational efficiency,” said Scott.

For more information on the range of Esko software solutions, visit our website at the address below. www.esko.com

In Australia, Schur® Star Systems manufactures quality flexible packaging and pouches for local

Schur Statistics

• 100 PERCENT of Schur’s companies work with sustainable solutions

• 22 PERCENT female leaders across all companies

• ALL COMPANY cars will be hybrid or electrical by 2030 food, cosmetics, and pharmaceutical customers.

“We have our own laboratory in Thomastown, Victoria, where we constantly seek to develop our material to innovate and make it sustainable. An example of this type of sustainable innovation is our recently developed Schur® Lid,” Quinn informs us.

“The Schur® Lid is a polyolefinbased structure developed locally in our laboratory specifically for the Australian market. It is available in mono and/or multi-layered laminated versions and can be used as a direct replacement for current polyethylene terephthalate (PET) film lid sealing to PET trays for ready meals and other retail packs that require a recyclable option.”

Schur has made significant investments in its Australian operations to create a world-class facility. This includes the recent heating and cooling of the entire factory, and the addition of several new printing, pouch and slitting machines.

Focusing On The Future

With 176 years of expertise