8 minute read

SUSTAINABILITY AND ESG IN THE ASPHALT INDUSTRY

by ORBA/OAPC

SUSTAINABILITY AND ESG IN THE ASPHALT INDUSTRY

By: Donn Bernal

The word sustainability is being used generously nowadays. The Merriam-Webster dictionary defines it as “being a method of harvesting or using a resource so that the resource is not depleted or permanently changed.” So how does sustainability work in asphalt? The word can be applied to many things including materials and processes. However, it is taken a step further in the corporate or business world and more aptly known as ESG or Environment, Social, and Governance. In the asphalt industry, there is much we can do to have a large impact on ESG, particularly on the “E”.

In recent years, owners such as the municipalities and the provincial government have started to face pressure by their constituents to have an ESG policy including reviewing their environmental practices for a net zero future. Many private and public corporations are now building carbon effects into their bidding practices. There are many things the asphalt industry is already doing to be sustainable to contribute to the “E” in ESG, and a number of these processes or technologies are mainstream enough to make an impact to the environment. We, as an industry, must be prepared with tools, resources, and information to show that asphalt is one of the most sustainable materials in the world, ensuring that it continues to be the product of choice.

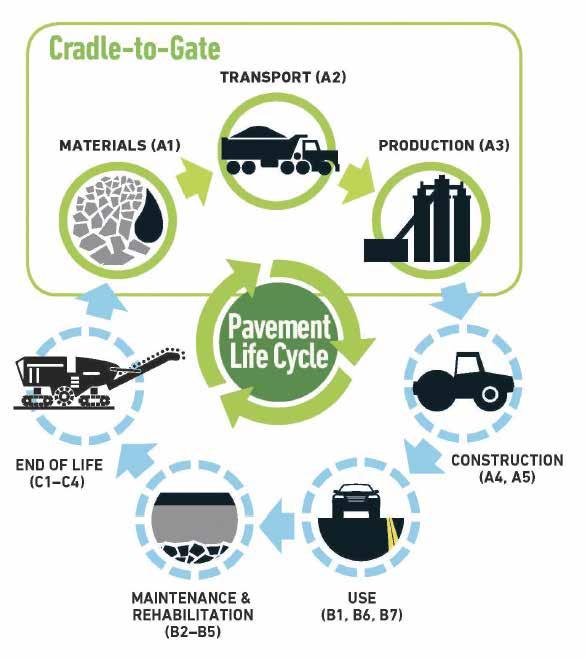

We are also seeing states such as Colorado building environmental best practices such as environmental product declarations (EPDs) into their bidding and contract requirements. EPDs measure the cradle-to-gate CO 2 equivalent effects as it has little to no control over the rest of the pavement life cycle that includes construction, use, maintenance and rehabilitation, and end of life. “Cradle-to-gate” is a phrase that you will hear a lot when sustainability is discussed and looks at the carbon impact of a product or material. In the case of asphalt mixtures, it includes the carbon effects of the extraction of the aggregates and asphalt cement, the transportation to the asphalt plant, and the manufacturing of the asphalt mixture right to the point it leaves the gate of the asphalt plant.

Through the National Asphalt Pavement Association (NAPA), the U.S. already has a system in place for asphalt to create EPDs and Ontario is working on a similar system with the support of OAPC, NAPA, and the National Research Council (NRC). If and when this happens, the system can be expanded across Canada. NRC Canada through its research program is committing to reduce its greenhouse gas (GHG) emissions by 40 to 45 per cent by 2030 (relative to 2005 levels) and net zero emissions by 2050. It is imperative that they support the areas of construction practices/construction materials and bio-energy to reach these ambitious goals.

How can we as an industry support environmental best practices? It starts with the ingredients of an asphalt mixture — aggregates and asphalt cement. We must make a conscious decision about the materials’ carbon emissions and where the materials are purchased from. It is no longer just about the price but also the carbon emission equivalent effects. Aggregates and asphalt cement suppliers will also have their own EPDs to help you make this decision.

Next, we will not be able to control the fuel that the carrier uses to get the materials to the asphalt plant, but we can control the distance travelled to the asphalt plant to reduce the carbon emission equivalent effects. All these variables are part of the EPD equation. There are logistics companies in North America trialling trucks that are electrified or using hydrogen, but that is still in the early stages. These initiatives will reduce emissions and help the EPD. Emissions from material extraction and transportation are one of the largest sources of CO 2 equivalent emissions in an EPD, so it is important that the suppliers and carriers we choose have similar mandates that our asphalt industry is progressing to and want to achieve as it pertains to sustainability.

With the sources of materials selected, the asphalt mix design can play an important role as well in developing a sustainable pavement. Even in operational best practices, the asphalt mix design is often overlooked. Having the correct combination or proportion of aggregates can help reduce moisture content, start/stops at the plant, and material wastage.

Reclaimed asphalt pavement (RAP) plays a key role in reducing the CO 2 equivalent emissions. Since RAP has already gone through the plant once before, it is not double counted in the EPD calculations. So not only are we recycling the aggregates and asphalt and reducing material cost, CO 2 equivalent emissions have been significantly been reduced as well for the asphalt mixture. A win-win situation!

Warm mix asphalt technology is the second significant item to RAP that improves sustainability of the asphalt. By allowing the plant to operate at a lower temperature of as much as 20 degrees Celsius, CO 2 equivalent emissions are reduced significantly and the life expectancy of the asphalt mixture is improved as the asphalt cement is not oxidized at the same degree as in hot mix asphalt. This is a technology that we must embrace more as it is a proven technology through studies and trials for the last 20 years. It is time to make it mainstream in Ontario and Canada.

Asphalt technology innovations such as warm mix asphalt, performance enhancing (rutting resistance, thermal cracking resistance, fatigue resistance) additives, and efficient material use including the use of RAP all play a part in a better performing pavement. Furthermore, asphalt pavement’s sustainability could be improved by using long-life asphalt mixtures produced by using a balanced mix design approach defined in AASHTO PP105-20 as “asphalt mix design performance tests on appropriately conditioned specimens that address multiple modes of distress taking into consideration mix aging, traffic, climate and location within the pavement structure.”

At the asphalt plant, reducing energy usage and emissions are the prime methods to run an efficient operation. Reducing moisture at the stockpiles, keeping the loader bucket 12 inches from the ground to feed the cold feed bins, insulating the dryer shell, managing plant start and stops, and more effective pipe insulation are just some of the many best practices at the plant. It can be taken a step further by looking at alternate energies and technologies. We are not quite there to switch 100 per cent to hydro power or renewable energy with the amount of energy required to turn the large motors and heat the aggregates, but components of the operation can be converted. The use of wind, solar, and steam energy technologies have advanced significantly to provide energy with minimal efficiency losses that it can make a significant enough effect in cutting down carbon emissions at the asphalt plant. In the meantime, switching to natural gas or liquified natural gas from fuel oil or recycled oil helps the asphalt plant run cleaner.

At the paving operation, new technologies such as intelligent compaction which uses GPS — and most likely AI in the future — to aid the roller operator to create efficient rolling patterns is already happening. More efficient engines and carbon capture

The asphalt industry can also play a role in the other two components of ESG. The Social component is the organization’s impact on society internally and externally. This could mean how its treats its employees, how it evaluates and chooses it supply chain, and community relations. Within the asphalt industry and our associations, we see scholarship or development programs for skilled trades, Women in Asphalt, and diversity and inclusion initiatives. These all contribute to make an impact on society and especially our employees and families. The Governance component applies to how to make impact investments in the company to ensure its sustainability and not just focusing on profits. What financial measures can be put in place so that people and planet are accounted for in the equation? It can also be called sustainable investing.

Even a small business can commit to Social and Governance practices. These commitments can be evaluated internally or be advertised publicly to inform investors or stakeholders of the business’s sustainability practices. There is lot of information to learn and understand with new and exciting concepts that are constantly evolving, but the basics don’t change: if we continue to strive to operate efficiently and be conscious of reducing emissions in various ways, we will be more than halfway to an “overall” sustainable asphalt pavement. And if we can make conscious decisions and collaborate/partner with all the stakeholders, the ambitious GHG emission targets can be achieved and sustainability attained.

Donn Bernal, P.Eng, MBA is Principal of Corfinium Solutions Inc. (corfinium.xyz).