2 minute read

How image digitalisation and data mining help to improve the surface quality of hot rolled steel

Enhancing the surface quality of hot rolled steel is beneficial for our customers. Ideally, the oxide scale formed during the final stage of the hot-rolling process and cooling phase is thin, compact and adherent. With such a perfect scale, hot-rolled steel is easy to shape, suitable for direct painting or glueing, and keeps steel shops cleaner.

Those interesting features require particular processing at the hot-rolling mill under specific conditions. At the same time, the grade’s mechanical properties must remain within specifications. When conditions are fulfilled, the oxide scale is made of a correct balance and morphology of multiple metallic and oxide compounds. This is what the theory in the field of materials science tells us, and it’s confirmed by dedicated experiments launched on lab scale on small samples. The next challenge is to get it on coils up to 25 tonnes in weight, in a large variety of gauges and grades!

FROM TEXTBOOK SCIENCE TO HOT-ROLLED COIL MONITORING

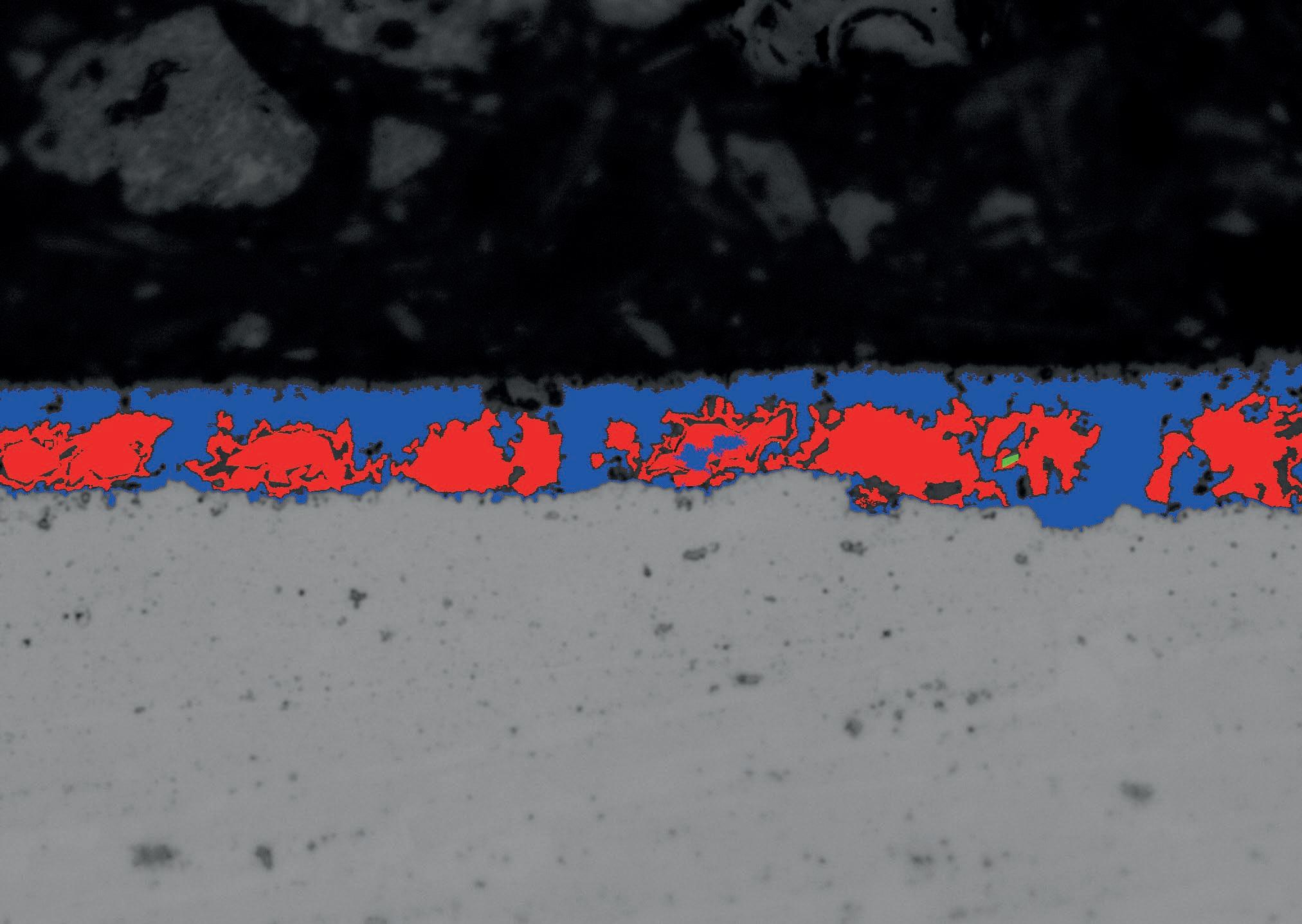

That’s why we used a stepwise approach. At first, a snapshot was taken from several sources to evaluate the current surface properties per production line and steel grade. This information allowed the OCAS team to capitalise on the behaviour of the oxide scale on 2 different levels. On the scientific level, analyses using modern tools such as SEM, EPMA (morphology from top & cross section, elementary composition, XRD quantifying phases) were launched. Image digitalisation was used on the optical microscope to quantify the oxide transformations. On a more practical level, quick, easy and reliable test methods were developed. By using these tests, production mills can monitor operations directly during production. The main test consists of performing a tape test on the surface and subsequent evaluation to categorise the obtained surface quality swiftly. Based on positive laboratory investigations done by OCAS on production samples, the mills launched trials to adapt their process conditions for improved scale layer formation.

BRINGING IN DATA MINING

This phase was an opportunity to launch a data mining exercise by merging scientific and experimental results. A total of 400 samples, originating from 5 different production mills, consisting of multiple steel grades, were compiled. The data cover productions launched over the entire year of 2020. Then, the result obtained after digitalisation was linked to the main characteristics and process parameters of each coil. Surface quality i.e. is linked to steel grade, gauge and metallurgical processing.

Dedicated lab scale experiments launched on small samples confirmed the good data analysis protocol. From there, the approach was implemented on industrial scale on a whole range of steel grades and gauges.

Marc Leveaux

Cross section showing the scale on hot rolled steel.

Automated qualification of the different oxide compounds.