15 minute read

Our research highlights

from Annual Report - 2020

by NUS-CDE

Reinforcing

our research impact

The momentum of research remained unabated at NUS Engineering despite the pandemic and various safe management measures. During the year, our faculty, researchers and students pushed on to make numerous groundbreaking discoveries that promise higher productivity, a greener future and improved, healthier lives.

Durable medical electrodes from a materials breakthrough

Aflexible, adhesive and conductive organic polymer ideal for use as dry medical electrodes has been developed in a crossdepartmental collaboration between Engineering researchers.

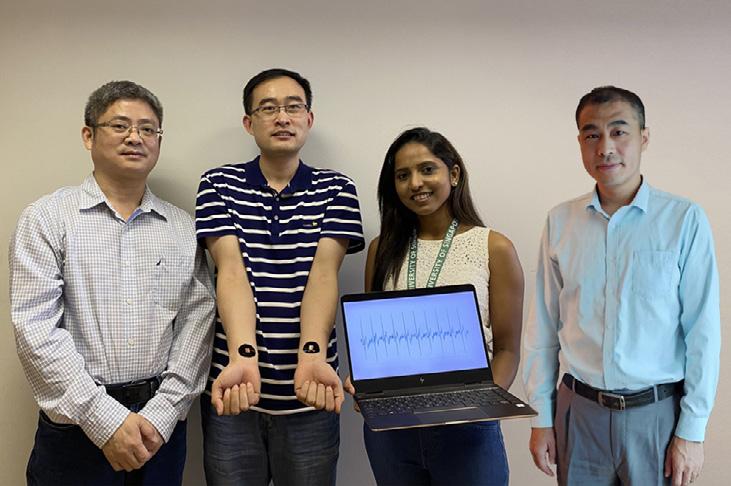

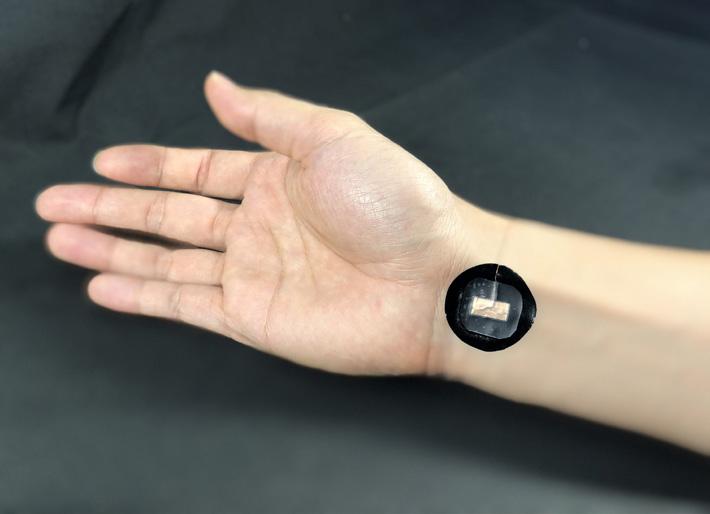

Compared to conventional “wet” electrodes which rely on a gel or liquid to detect biosignals – and which can dry out over time to give lower quality signals – the team says the dry electrodes are stretchable, conductive and do not require adhesive to attach to the patient’s skin. They also do not wear out, allowing for longterm reuse while delivering consistent signal quality. Developed by Dr Zhang Lei and Associate Professor Ouyang Jianyong from Materials Science and Engineering and Assistant Professor Ren Hongliang and PhD candidate Kirthika Senthil Kumar from Biomedical Engineering, the team named the new polymer PWS.

Dry yet robust, the PWS polymer can be cast into different shapes for various applications in patient diagnosis, physiotherapy and rehabilitation. There is also potential for it to be used in the development of more responsive human-machine interaction interfaces. When tested in a clinical setting, the PWS electrodes detected tiny changes in the heartbeat of a patient diagnosed with atrial fibrillation (irregular heartbeat), and captured muscle strength readings of a patient with muscular dystrophy. These outcomes affirm the suitability of the PWS electrodes for longterm patient monitoring.

(From left to right) Assoc Prof Ouyang Jianyong, Dr Zhang Lei, PhD candidate Kirthika Senthil Kumar, and Asst Prof Ren Hongliang.

Read more about this online. https://cde.nus.edu.sg/ durable-medical-electrodesfrom-a-materialsbreakthrough/ A prototype of the new dry PWS electrodes.

A low-power, highly responsive and reusable sweat pH monitor

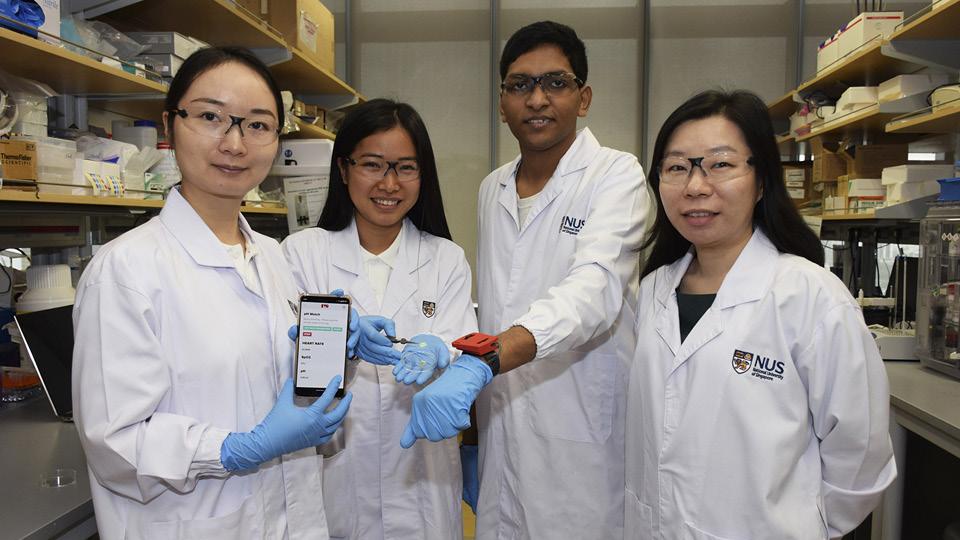

Amultidisciplinary research team has developed an add-on to wearable health monitoring gadgets to better inform users about their health.

The novel sweat pH monitor, which can be easily integrated into existing fitness trackers or smartwatches at a low cost, is able to continuously measure and monitor the acidity or alkalinity level of a user’s sweat along with heart rate and oxygen concentration.

The team behind the monitor includes Mr Ananta Narayanan Balaji, a doctoral student from Electrical and Computer Engineering, doctoral student Ms Chen Yuan and Assistant Professor Shao Huilin from the NUS Institute for Health Innovation & Technology (iHealthtech) and Biomedical Engineering, and Dr Wang Bo and Professor Peh Li-Shiuan from NUS Computing. Working in tandem with existing pulse oximeter chips in fitness trackers and smartwatches that measure the heart rate and oxygen saturation levels of users, the pH sweat sensor changes colour when it comes into contact with different sweat pH, matching the recording capabilities of the pulse oximeter. Besides an accuracy of about 90%, the pH watch is energy efficient. While the sensor does not require an independent power source, the pH sensing algorithm uses less than 0.01% of the total power consumption of a smartwatch. It also only requires 20 KB of Random Access Memory (RAM) for data processing.

By integrating the custom-made pH sensor (middle) and pH sensing algorithm into fitness trackers or smartwatches with existing built-in pulse oximeter, the pH Watch can simultaneously monitor the pH value of a user’s sweat, heart rate and blood oxygen saturation values. (From left to right) Dr Wang Bo, Ms Chen Yuan, Mr Ananta Narayanan Balaji and Asst Prof Shao Huilin came up with the pH Watch that informs users about their health from their sweat pH.

Read more about this online. https://cde.nus.edu.sg/a-lowpower-highly-responsive-andreusable-sweat-ph-monitor/

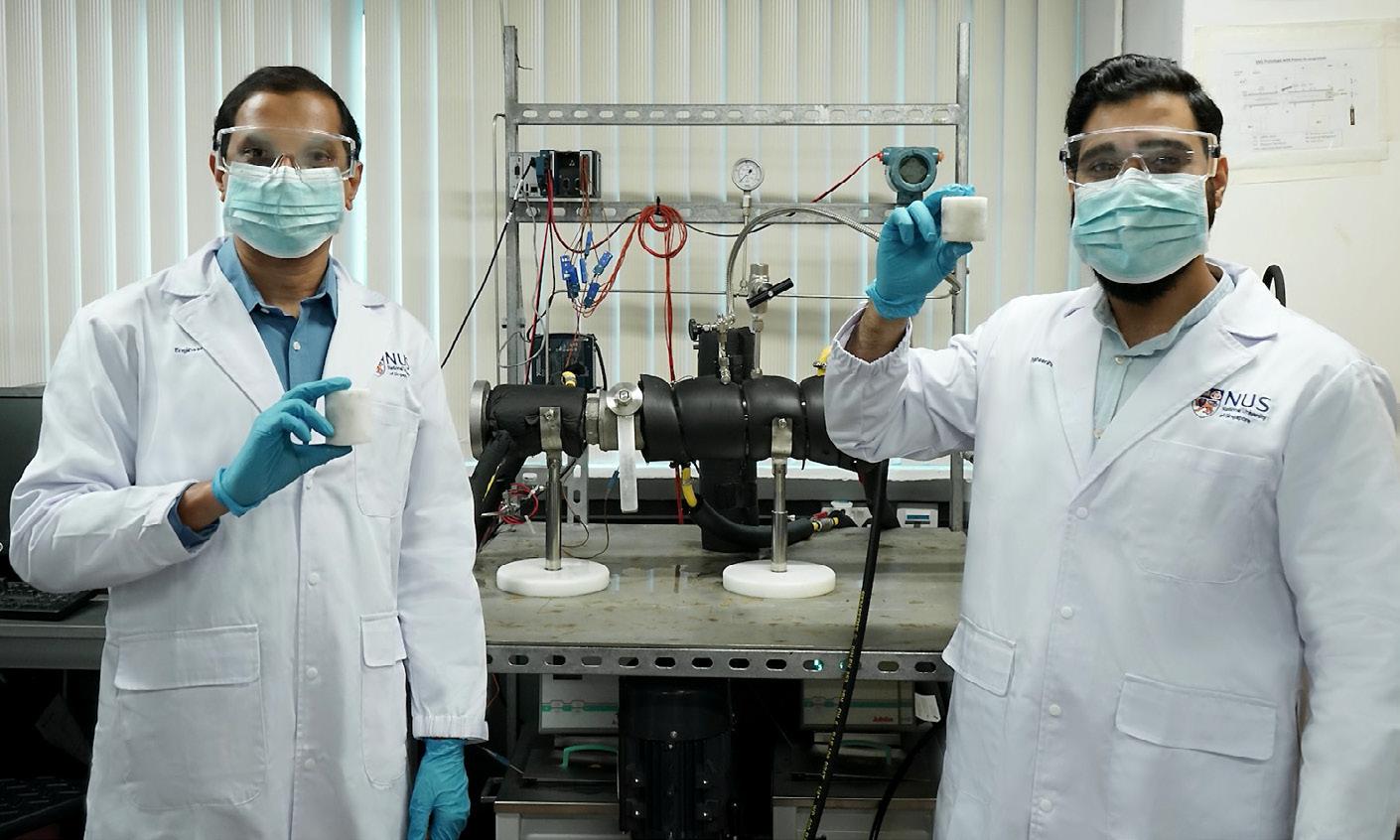

A fast, safe and economical way to store natural gas

Associate Professor Praveen Linga from Chemical and Biomolecular Engineering and his team have devised a way to convert natural gas into gas hydrates or Solidified Natural Gas (SNG) – a non-explosive solid that can be easily transported and stored long-term.

Using a low-toxicity additive mixture which is made mostly of water, the conversion process from gas into solid can be completed in just 15 minutes. The new process converts high volumes of gas into pellets consisting of molecules of natural gas trapped in ice-like “cages” formed by water molecules.

These pellets can be easily transported and stored for later use in conditions no different to standard domestic freezers. The discovery opens the way to economical long-term storage of natural gas, helping to avoid power supply disruptions and boosting the energy security of natural gas importers like Singapore.

Read more about this online. https://cde.nus.edu.sg/icethat-burns-a-fast-safe-andeconomical-way-to-storenatural-gas/

“Our breakthrough can really be put into perspective when you consider that it takes millions and millions of years for gas hydrates to form in nature, yet with our correct addition of secret ingredients to the system in small quantities, the same process can be effected in the laboratory in a matter of minutes.”

– Dr Gaurav Bhattacharjee, Chemical and Biomolecular Engineering

Assoc Prof Praveen Linga (left) from Chemical and Biomolecular Engineering and Research Fellow Dr Gaurav Bhattacharjee found an economical way to keep natural gas.

Marrying chemical and biological processes to turn waste into treasure

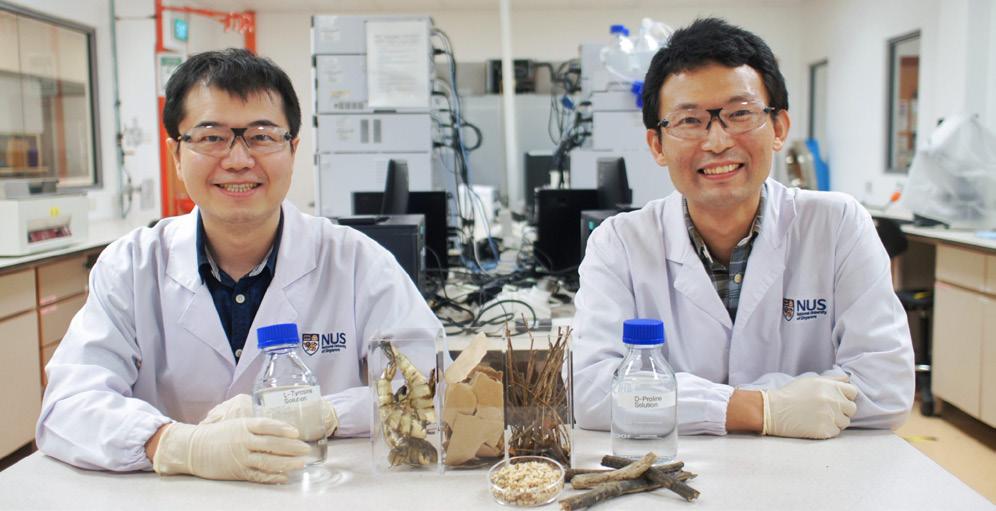

Associate Professor Yan Ning, Assistant Professor Zhou Kang and their team at Chemical and Biomolecular Engineering have created a new process which upcycles waste materials into high-value amino acids.

The team first applied chemical processes to waste materials to convert them into a substance that can be “digested” by microbes before specially engineered strains of bacteria are introduced to convert the substance into higher-value products like amino acids. Compared to conventional methods used for producing amino acids, which require sugars as the substrate, this method makes use of food and agricultural waste as raw materials and reduces costs significantly.

One initial application developed by the researchers turns waste prawn and crab shells into an essential ingredient for a drug to treat Parkinson’s disease. The process also can be adapted to convert food waste to Proline, a joint health supplement which

The team led by Assoc Prof Yan Ning (left) and Asst Prof Zhou Kang (right) has developed an integrated upcycling process to produce high-value amino acids from waste materials.

Waste prawn shells and wood chips are converted into high-value chemicals through the novel process.

boosts the formation of healthy collagen and cartilage.

Looking further ahead, the research team says the new process could be applied to turning carbon dioxide, one of the most prolific greenhouse gases, into ethanol and eventually even into labgrown beef. With the potential to be applied to different waste materials, the process can be tailored to cater to different types of waste and target end products.

“Our novel chemical-biological integrated workflow offers a general pathway to produce a variety of high-value organonitrogen chemicals. Given that these chemicals are found in a vast array of commercially valuable pharmaceuticals, pigments and nutrients, we are excited to expand our research and develop new methodologies to produce value-added chemicals from other abundant, locally available substrates found in Singapore.”

– Assoc Prof Yan Ning, Chemical and Biomolecular Engineering

Read more about this online. https://cde.nus.edu.sg/ marrying-chemical-andbiological-processes-toturn-waste-into-treasure/

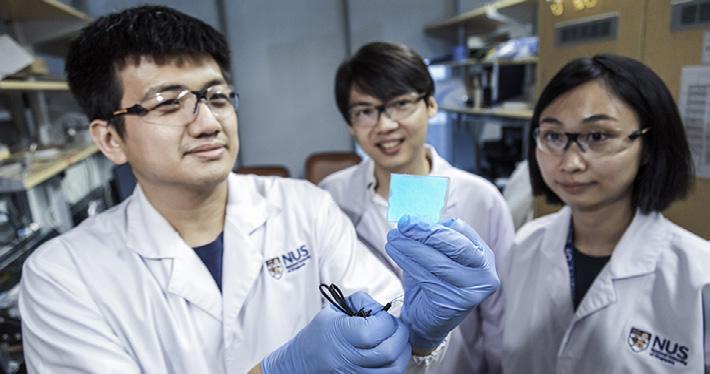

Creating world’s first monolayer amorphous film Smart suit wirelessly powered by a smartphone

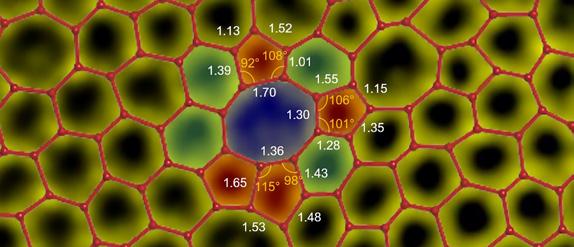

Aresearch team led by Professor Barbaros Özyilmaz, Head of Materials Science and Engineering, have synthesised the world’s first one-atom-thick amorphous material. Previously thought to be impossible, the discovery of monolayer amorphous carbon (MAC) could settle a decades-old debate about exactly how atoms are arranged in amorphous solids, and open up a range of potential applications.

This major research breakthrough could be of commercial value for batteries, semiconductors, membranes and many more uses.

The team grew the material and studied its properties and potential areas of application. Other work on imaging and theoretical simulations was carried out by research teams at universities in Japan, China and the USA.

“With MAC, we have shown for the first time that fully amorphous materials can be stable and free-standing in single atomic layers. Amorphous materials are of great technological importance, but surprisingly, they remain poorly understood from a basic science point of view,” said Prof Özyilmaz.

Prof Barbaros Özyilmaz and his team have created the world’s first atomically thin amorphous carbon film. The amorphous structure has widely varying atom-to-atom distance, unlike crystals.

Read more about this online. https://cde.nus.edu.sg/nusscientists-create-worlds-firstmonolayer-amorphous-film/ The smartphone-powered suit is designed by a team led by Asst Prof John Ho (left).

Assistant Professor John Ho and a team from the NUS Institute for Health Innovation & Technology (iHealthtech) and Electrical and Computer Engineering have developed a smartphone-powered suit capable of providing athletes with physiological data such as their posture, running gait and body temperature while they are out on the field.

The smart suit is made up of web-like circuitry with the inductive patterns acting as hubs at strategic locations. Custom-made sensors placed at those hubs transmit data back to the smartphone and are powered by the smartphone’s near-field communications (NFC) chip, removing the need for batteries. This reduces a significant amount of weight while enabling the collection of data from multiple areas on the body.

Potential applications include athletic performance optimisation, clinical diagnosis of spinal disorders and round-the-clock health monitoring.

Moving forward, the team plans to develop new sensors to increase the range of data collected and work with professional athletes to help them monitor their physiological signals during training.

Read more about this online. https://cde.nus.edu.sg/nus-develops-smartsuit-wirelessly-powered-by-a-smartphone/

A multitasking microbe to purify wastewater

Assoc Prof He Jianzhong (left), Research Fellow Dr Wang Qingkun (right) and team discovered the Thauera sp. strain SND5 after isolating and testing various strains of bacteria from wastewater samples.

Ateam led by Associate Professor He Jianzhong from Civil and Environmental Engineering have discovered a new strain of bacterium that has the ability to remove nitrogen and phosphorus from sewage.

The strain, called Thauera sp. strain SND5, is not only able to remove nitrogen and phosphorus faster than other tested microbes, it also offers significant energy savings compared to conventional nitrogen removal processes of nitrification and denitrification.

With some existing sewage treatment methods, greenhouse gases such as nitrous oxide are released. Through converting ammonia into harmless nitrogen gas, the microbe solves this problem while concurrently removing phosphates present in sewage water.

This discovery significantly reduces the high operational costs and emission of greenhouse gases associated with traditional wastewater treatment methods.

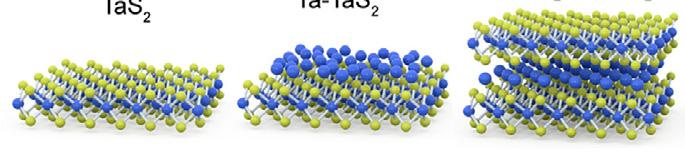

A new library of atomically thin 2D materials

Researchers have created a whole new library of atomically thin, two-dimensional (2D) materials using a novel and powerful approach of engineering the composition of transition metal dichalcogenides.

Materials that are atomically thin offer a platform to explore a wide range of intriguing physical properties and could provide many future applications. ‘Transition metal dichalcogenide monolayers’, for example, are atomically thin semiconductors which are tipped to bring about the next generation of transistors, solar cells, LEDs, and more.

Transition metal dichalcogenide monolayers take the form MX2, with ‘M’ being a metal atom from the transition block of the periodic table and ‘X’ being a chalcogen atom (such as S, Se, or Te). However, fine-tuning the composition of 2D transition metal dichalcogenides to make new materials other than the standard compounds is usually challenging.

The team led by Professor Stephen J. Pennycook from Materials Science and Engineering and Professor Loh Kian Ping from NUS Chemistry, has synthesised and characterised for the first time an atlas of atomically thin materials based on inserting the same metal atom between two transition metal dichalcogenides monolayers.

This insertion is known as intercalation, hence the researchers have named this new library ‘ic-2D’, to denote a class of materials where the atoms ‘intercalate’ themselves into the gap between the layers of crystals.

Growth mechanism

TaS2 Ta-TaS2 TaS2 -Ta-TaS2

This schematic diagram depicts the step-by-step process of how a typical Ta7S12 ic-2D material is formed.

Read more about this online. https://cde.nus.edu.sg/amultitasking-microbe-to-purifywastewater/ Read more about this online. https://cde.nus.edu.sg/a-new-libraryof-atomically-thin-2d-materials/

System profiles telomeres in under three hours

A magnified image captured by the device used to perform STAR assay. Different fluorescent intensities reflect the length variations in individual telomere molecules.

An important early indicator of cancer and other age-related diseases is abnormalities in telomeres – tiny protective caps located at the ends of chromosomes.

Assistant Professor Cheow Lih Feng from Biomedical Engineering and the NUS Institute for Health Innovation & Technology (iHealthtech) has developed a novel method to measure the length of individual telomeres in less than three hours.

Conventional methods for telomere measurements in clinical settings are often timeconsuming, require skilled operators, and yet offer imprecise information required to accurately diagnose or determine telomere abnormalities. In contrast, with Asst Prof Cheow’s Single Telomere Absolute-length Rapid (STAR) assay, the telomere maintenance mechanism in cancer cells can be accurately determined with a high level of detailed information.

The combination of rapid workflow, scalability and single-molecule resolution of the newly developed system enables the use of telomere length distribution as a biomarker in disease diagnosis. It will be particularly useful for diagnosing telomere maintenance mechanisms within clinical time scales, to determine personalised, therapeutic or preventive strategies for patients.

Read more about this online. https://cde.nus.edu.sg/newsystem-to-profile-telomeresin-less-than-3-hours/

New material for nextgeneration wearables and soft robots

Asst Prof Benjamin Tee (centre), Mr Wang Guanxiang (left) and Dr Tan Yu Jun (right) worked on the electronic light-emitting, self-healing material.

Assistant Professor Benjamin Tee and a team from the NUS Institute for Health Innovation & Technology (iHealthtech) and Materials Science and Engineering have developed a new stretchable material which when used in light-emitting capacitor devices, enables highly visible illumination at much lower operating voltages.

In addition, the material is resilient to damage due to its self-healing properties.

Named HELIOS (which stands for Healable, Low-field Illuminating Optoelectronic Stretchable), devices enabled with the new material can turn on at voltages that are four times lower, and achieve illumination that is more than 20 times brighter than existing stretchable lightemitting capacitors.

The low power consumption also means that HELIOS can achieve a longer operating lifetime, be utilised safely in human-machine interfaces, and be powered wirelessly to improve portability.

HELIOS is also resistant to tears and punctures. The reversible bonds between the molecules of the material can be broken and reformed, thereby allowing the material to self-heal under ambient environmental conditions.

Read more about this online. https://cde.nus.edu.sg/new-electronicmaterial-for-wearables-and-soft-robots/

Five times more efficient data transfer

Dr Viveka Konandur (left) and Prof Massimo Alioto (right) testing the network-on-chip in a machine learning application.

Led by Professor Massimo Alioto from Electrical and Computer Engineering, a team of researchers has developed an innovative technique that allows the transfer of bits (the basic unit of information in computing) across a silicon chip up to five times more efficiently than standard setups.

This breakthrough is advantageous for applications such as machine learning, where many processing cores called “neurons” are constantly exchanging data, and require ever-increasing levels of power. Such power consumption must be significantly reduced to allow for extended battery life in next-generation smartphones, smartwatches, and other mobile devices that require higher computing performance.

The invention could pave the way for a new generation of intelligent high-performance systems, while fitting the limited power budget of battery-powered systems.

Read more about this online. https://cde.nus.edu.sg/five-times-more-efficientdata-transfer/

“Our silicon chip demonstration sets a new standard for power efficiency, without modifying the building blocks, such as transmitters and receivers, that are typically used in these setups, allowing its easy adoption in existing designs. Given that power, performance and cost are all fundamental drivers of artificial intelligence applications, our invention simplifies the integration of next-generation intelligent systems.”

– Prof Massimo Alioto, Electrical and Computer Engineering

Ateam of researchers led by Associate Professor Duong Hai-Minh and Professor Nhan Phan-Thien from NUS Department of Mechanical Engineering have developed the world’s first aerogels made from scrap rubber tyres.

Most aerogels are brittle with a tendency to fragment and pulverise. Rubber aerogels on the other hand can spring back to their original shape after compression.

The new rubber aerogels demonstrate remarkable properties – they are extremely light, highly absorbent, very durable, and very efficient at trapping heat and sound. For example, compared to commercial foam, the aerogels are not only lighter and stiffer, but also up to 27% more effective in absorbing sound.

By upcycling waste rubber into products of higher commercial

value, this new technology promotes a wider use of scrap tyres, and offers an eco-friendly way to recycle waste rubber which is non-biodegradable.

As a next step, the team is looking to work with industry partners to commercialise and scale up the technology. They will also be conducting further studies to enhance the performance of the rubber aerogels, explore other applications as well as the use of other types of waste materials for conversion into aerogels.

Assoc Prof Duong Hai-Minh (front row, first from left) and Prof Nhan PhanThien (front row, centre), developed the world’s first aerogels made from scrap rubber tyres.

Read more about this online. https://cde.nus.edu.sg/the-worldsfirst-aerogels-made-from-scraprubber-tyres/

“Potential markets of aerogels are huge. For example, vehicle noise and thermal comfort are vital in vehicle designs – the global automotive heat and sound insulation solution markets are expected to reach US$3.2 billion by 2022. In addition, the global oil spill management market is expected to reach US$182.7 billion by 2025.”

– Prof Nhan Phan-Thien, Mechanical Engineering