8 minute read

Industry Advisor

from January—March 2020

by NMEDA

Harry Baergen was previously the Regulation Enforcement Officer for Transport Canada. Currently, he acts as the Compliance Review Program (CRP) Coordinator for NMEDA.

If you have any questions about the contents of this article, or about the NMEDA CRP, contact Harry Baergen at 778.888.2210.

Advertisement

This is an update to a previous article about difficulties NMEDA manufacturing members (alterers) have in obtaining test reports for F/CMVSS 302, “Flammability of Interior Materials.” The preceding article was published in the 2014 summer issue of the Circuit Breaker and shortly after that, on September 01, 2014, the Compliance Review Program (CRP) began asking alterers for F/CMVSS 302 test reports. Since then, NMEDA member manufacturers have been making concerted efforts to obtain test reports from material suppliers, but proper test reports have generally not been forthcoming. In the meantime, CRP has conceded to accept statements from adaptive vehicle manufacturers, in lieu of test reports, for non-ignitable and self-extinguishing materials, such as

By Harry Baergen – Autoregs Consulting NMEDA CRP COORDINATOR

flooring and plastics. However, test reports for combustible materials, such as seating material, are still not readily available from suppliers. Although, seat suppliers have been telling CRP that full test reports are available if requested, CRP is finding this to be inaccurate. First, to revisit the preceding article for some background, the purpose of F/CMVSS 302 is to reduce death and injuries caused by vehicle fires. F/CMVSS 302 is often overlooked in the adaptive vehicle industry, because an adaptive vehicle conversion does not add as many flammable materials Standard 302 has been severely criticized for being too lenient, especially for being a horizontal test. Basically, the standard requires that certain specified materials that are within 13 mm (1/2 inch) of the occupant compartment air space shall not burn more than 102 mm (4 inches) per minute when tested horizontally in a burn cabinet according to the test procedure. This is a generous burn rate, but it is only intended to allow time for occupants to exit a burning vehicle. Although, in the adaptive vehicle industry, some moral consideration might be given to ...in the case of aftermarket seats, or other flammable materials, a comprehensive, verifiable, F/CMVSS 302 test report should be demanded from the supplier as a condition of procurement. ” “

to the OEM vehicle as some other industries do. However, F/CMVSS 302 does apply to alterers of adaptive vehicles and the standard must be considered when certifying an adaptive vehicle. the possibility of a disabled person requiring more time to exit a burning vehicle in a crash.

only some waste pieces of material or composite material that measure 102 X 356 X 13 mm (4 X 14 X 1/2 inches). It is also one of those standards for which engineering analysis cannot replace an actual test, which means the test is required by law. Standard 302 is also unique in that flammable materials need to be tested on a more ongoing basis, even if the vehicle design and material suppliers do not change.

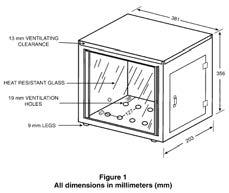

Certifying to F/CMVSS 302 does not require a highly skilled person. The metal burn cabinet can be purchased for several hundred dollars or it can be constructed according to the NHTSA test procedure referenced

in the attached chart. Ideally, a 4

X 14 inch test specimen can be cut

from each roll or shipment from the

material supplier and tested in the

burn cabinet after the specimens

are conditioned for 24 hours at 21 0 C and 50% humidity. Material that is

self-extinguishing, such as flooring or

plywood, need not be tested as often.

On the other hand, material that has

a high burn rate, for example, 3 1 / 2 inches per minute, or treated material,

should be tested more often. The burn tests should be timed, photographed, documented, dated and filed to include the information listed in the attached chart.

Traditionally, obtaining proper F/ CMVSS 302 test reports has been problematic in other conversion industries as well. One problem is that up-fitters tend to rely blindly on material suppliers who may not be as familiar with automotive requirements as they are with other standards. Material suppliers tend to only provide: certification statements, test reports convoluted lack information. Test reports should clearly state that the material was tested according to F/CMVSS 302 test procedure, not just to equivalent tests, such as 1SO 3795 or ECE Reg. No. 118 annex 6. The test report should state the date, the burn rates, burn sample measurements, describe or illustrate the burn cabinet, describe, with test information unrelated to standard 302, standard 302 reports with inadequate information, or test reports that are outdated. Also, the material suppliers, including seat suppliers, are usually aware that they are not responsible for the final vehicle certification, which includes F/CMVSS 302 in North America.

Albeit, seat manufacturers in the United States are responsible under the Vehicle Safety Act as component suppliers and are also responsible to report to NHTSA under the TREAD ACT (see Circuit Breaker article October – December 2019).

Considering the high-tech nature of the adaptive vehicle industry, testing for F/CMVSS 302 is one of the least complicated tests for the vehicle alterer and the applicability of F/ CMVSS 302 to an adaptive conversion is relatively minimal – except for aftermarket seating. For this reason, it may not be worthwhile for the alterer to test materials in-house. Therefore, in the case of aftermarket seats, or other flammable materials, a comprehensive, verifiable, F/CMVSS 302 test report should be demanded from the supplier as a condition of procurement.

To focus on the present-day problem, the test reports that CRP is receiving are mostly inadequate, outdated and or at least name, the material and show identified photographs of the test in the burn cabinet to prove that the test was actually carried out. The test should also state the location of the material in the vehicle, but this could be added by the vehicle alterer if necessary.

As mentioned above, very often the test reports that CRP receives are outdated. Outdated means more than 6 months old for combustible materials and very outdated means more than a year old. As stated above, material with a higher burn rate should be tested more often than non-ignitable or self-extinguishing materials. CRP has been challenged by seat manufacturers who argue that there is no requirement in federal law to test materials on an ongoing basis and they are correct. However, there is federal law that requires vehicle manufacturers to certify that their vehicles meet all federal standards. There is no way of knowing whether the altered or modified vehicle meets

F/CMVSS 302 without routinely testing the material as it arrives from suppliers or have the suppliers provide current test reports.

The NMEDA CRP is willing to assist a NMEDA member in trying to obtain F/CMVSS 302 test reports from suppliers or in obtaining or building a burn cabinet for in-house testing. During the writing of this article CRP has been communicating with one of the major aftermarket seat manufacturers who has committed to providing full test reports to NMEDA members by January 2020. It should also be noted that in exporting vehicles to Canada, Transport Canada will initially ask for CMVSS 302 test reports for all materials, or for selected materials, in the vehicle, including those non-ignitable or self-extinguishing materials that CRP temporarily accepts by statement.

Following here is a chart that may be useful in assisting the material supplier or seating supplier in establishing a proper test report:

F/CMVSS/ TSD 302 S4.1

S4.2

S5.1

Requirement Information for Test Report

Seat cushions, seat belts (if not labeled), headlining, arm rests, trim panels, head restraints, floor coverings, sun visors, curtains, shades, wheel house coverings, engine compartment coverings, padding and crash deployment elements must meet S4.2. Material that is within 13 mm of the vehicle occupant air space (face down) must not burn more than 102 mm per minute, separately or composite, when tested in specimens 102 mm wide by 356 mm long as specified in the test procedure S5.1, S5.2 and S5.3.

• All test reports must demonstrate test procedure, equipment, and instrumentation. • Include burn rates, part numbers, fabric material, location in vehicle, and date tested. • Include identified photographs showing material burning in cabinet. • If necessary, a material specimen may be kept horizontal on ‘piano wire’ across the width of the U frame at 25 mm intervals. • (See NHTSA test procedure TP-302-03 for exact burn cabinet build instruction templates.) • Test should not be more than 6 months old for higher burn rate material, 1 year for slower burn rate material, and 2 years for self-extinguishing or nonignitable material.

S5.2

S5.3 Material is held by two 10 X 25 mm U frames (not shown) with interior dimensions of 51 mm wide X 330 mm long, mounted 165 mm above bottom of cabinet. Material is lit by a 10 mm ID Bunsen burner with a natural gas temperature flame 38 mm in height. Flame is centered on open end of specimen with burner tip 19 mm below bottom of specimen. Expose to flame 15 seconds, then allow material to burn 38 mm and begin timing until flame is within 38 mm of closed end or where flame stops. Burn rate = 60 X (D/T). D = distance in mm, T = time in seconds.