2 minute read

Introducing a world-class conveying system

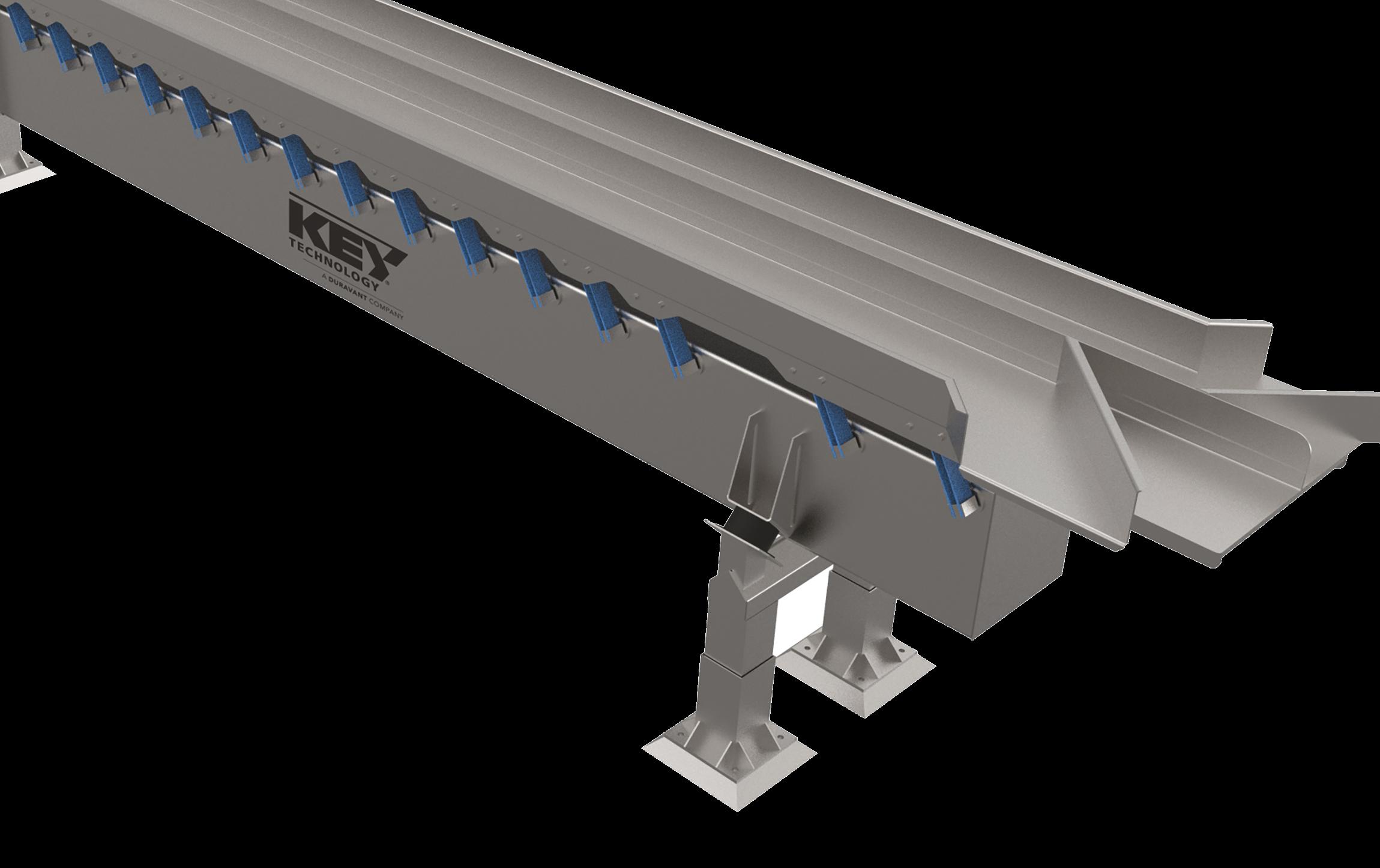

Key Technology, a member of the Duravant family of operating companies, introduces its Marathon vibratory conveyors with monobeam construction. These conveyors deliver world-class performance and reliability while the monobeam construction minimises the product footprint and enhances equipment sanitation to improve food safety.

Featuring a narrow frame, that’s less than half the surface area of traditional Marathon frames, monobeam shakers offer better access to the conveyor bed and fewer parts to clean. “When we launched our Iso-Flo shakers with monobeam in 2016, they were a huge hit. Customers immediately began asking for monobeam on our lengthy Marathon conveyors, so we started designing, building and testing. Now, we are getting great feedback from customers on this new model as well,” said Jim Ruff, vice president of process systems and integrated solutions at Key Technology.

conveyors position the frame and spring arms underneath the bed to maximise sanitation while improving operator access and safety. These shakers also enable workers to get closer to the bed for improved product visibility and ergonomics.

All Marathon conveyors use naturalfrequency vibratory motion to distribute bulk foods long distances on a single unit. Marathon can replace several shakers in a row, relying on only two independent, frame-mounted drives to improve efficiency and reliability. Additionally, fewer supports to the floor eases cleaning and sanitation. Two foot-mount, selfsynchronising motors transfer the force of the frame to the bed without mechanical joints to further improve efficiency, reduce maintenance and minimise downtime.

Marathon with monobeam is suitable for a wide range of bulk food applications, from raw receiving to packaging, including product collection, transfer and distribution. Unlike a traditional shaker, which has a frame and spring arms on both sides of the conveyor bed, monobeam

Key Technology tailors each Marathon using predictive modelling and finite element analysis to define the product

"Marathon with monobeam is suitable for a wide range of bulk food applications, from raw receiving to packaging, including product collection, transfer and distribution."

characteristics and deliver superiorperformance. Available in lengths 9m- 15m and widths from 50cm - 100cm,Marathon with monobeam can achieveconveying speeds greater than 15m/minute, depending on the application.

The conveyor bed can be tilted to draw product to one side and flow direction can be controlled with optional side outlet diverters. This product can also be built with end-mounted drop-out gates, diverters, end-mounted screens and covers when needed.

In addition to the sanitation enhancements from its monobeam construction, Marathon offers a variety of sanitary advantages. Its stainless-steel conveyor bed features a standard rotary polish within the product contact zone, which resists bacterial attachment and biofilm formation. Oil-free drives, elastomeric isolators, scalloped flat bars (if requested), internal ground arms and minimal laminations maximise equipment hygiene and help meet rising sanitary standards and regulatory requirements. The monobeam frame is sloped to prevent product and moisture build-up that can harbour bacteria. Marathon is available in four different finishing standards, and its rotary vibratory drives are available in either stainless steel or food-grade epoxy finishes.

Marathon with monobeam is suitable for fruits, vegetables, potato strips, potato chips, nuts, meat, poultry, seafood, dairy products, confections, snacks, cereals, grains, seeds and more. Like all Key equipment, these versatile conveyors are backed by Key’s industry-leading, five-year warranty, which ensures equipment reliability and limits the processor’s total cost of ownership. •

Heat and Control - www.heatandcontrol.com