4 minute read

Wastewater Fuels

Advertisement

www.wastewaterfuels.com

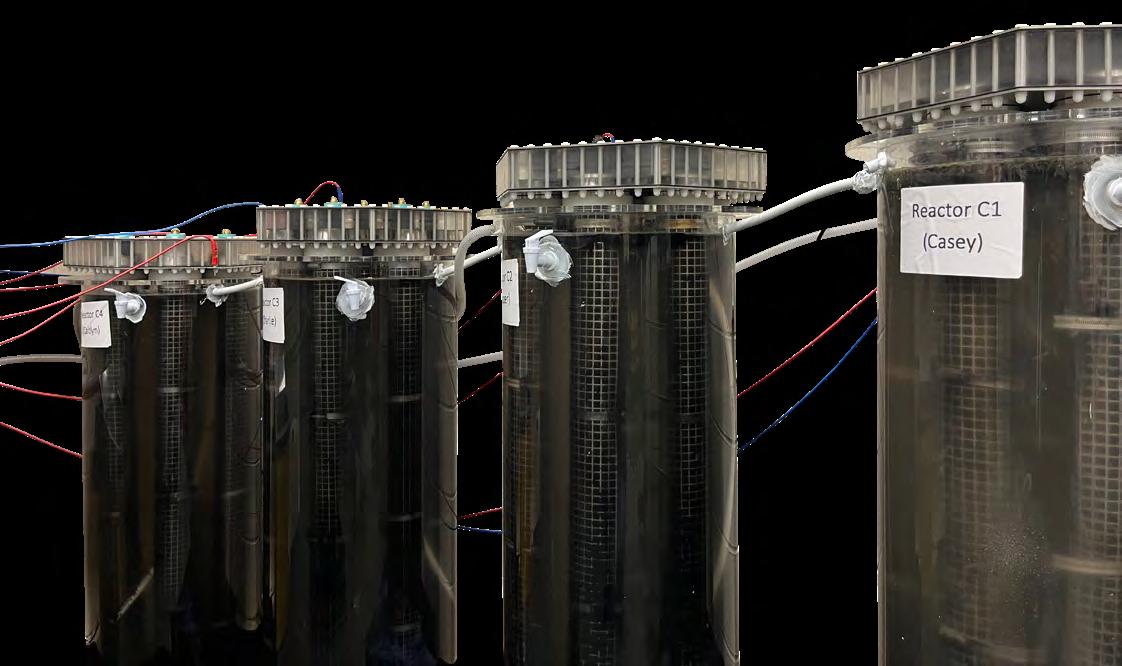

Wastewater treatment is an energy intensive and expensive industry. Over 80% of the world’s wastewater is untreated, resulting in high carbon emissions and environmental damage. Wastewater Fuels’ solution helps solve this challenge through its microbial electrolysis cell (MEC) that can treat sewage while producing renewable hydrogen gas.

The technology can be net energy positive, meaning it produces more energy than it uses. The technology therefore has significant potential to eliminate a large proportion of the energy demands of the water sector (or any sector that requires wastewater treatment including breweries, cattle farms and food waste).

The technology works by using microorganisms to break down the pollutants in wastewaters. This treats the wastewater, making it safe for discharge. Through the process of consuming these pollutants, the MEC is able to produce hydrogen gas from the by-products. In order to function, a small voltage must be supplied due to the system being anaerobic.

The system is modular, meaning that it can scale the number of units required to meet any demand. The company has assets designed to work in off-grid scenarios which are being funded by the UK’s Ministry of Defence, all the way to larger scale pilot trials.

If the company’s MECs were used to treat the UK’s domestic sewage and recover hydrogen, there is the potential to save 2.1 megatonnes of carbon dioxide per year, attributed to the reduced operational electricity requirement and the recovered hydrogen. This equates to 0.5% of the UK’s emissions and does not take into account the potential carbon savings or other industries where this could be deployed.

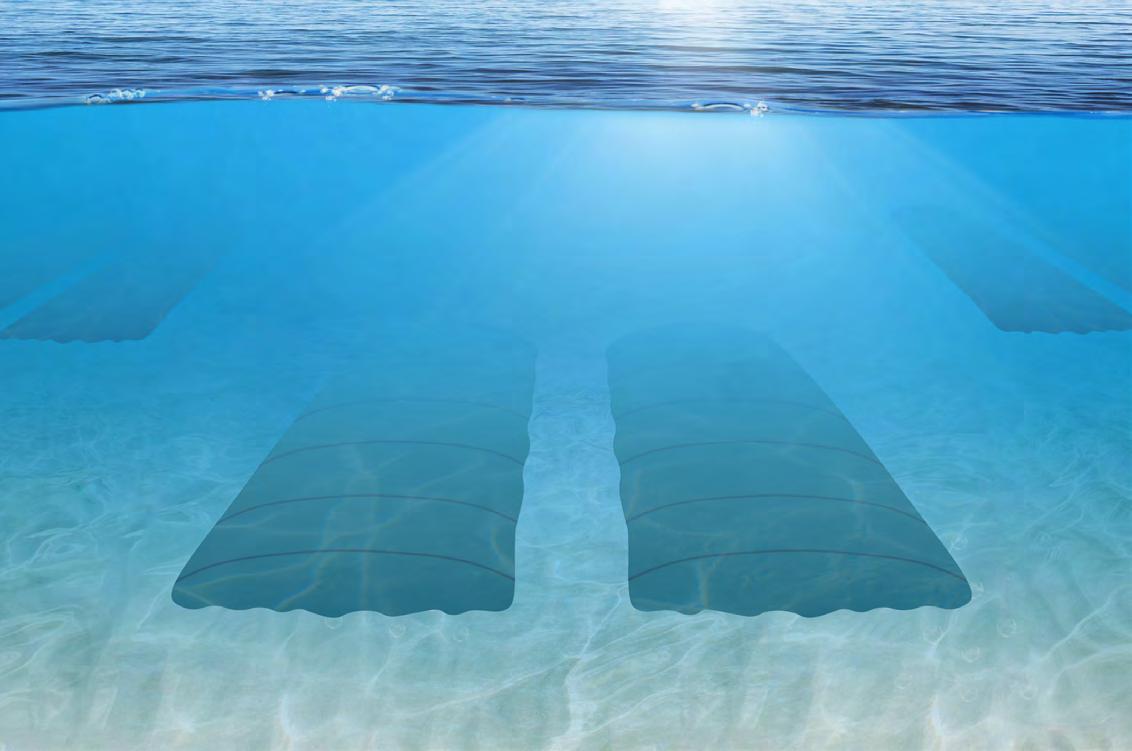

Waterwhelm is paving the way in enabling low cost, green hydrogen production with its novel forward osmosis desalination technology, which turns salt water into fresh water. The company’s solution will enable green hydrogen production in regions where fresh water is unavailable. Nearly 85% of global green hydrogen projects slated for 2040 will require desalination for water supply. However, desalination technologies have high capital costs, and they are also energy intensive because they operate at high pressures.

Waterwhelm presents a solution using a low pressure semi-permeable membrane and utilising waste heat from industrial processes, which promises significant savings in operating and capital costs, with the opportunity to accelerate greenhouse gas emissions reduction compared to the traditional reverse osmosis method.

Based at a treatment site in Edinburgh, the company is utilising the waste heat generated during the wastewater treatment process. This is used to clean the brackish water which would normally be discharged into the sea as a byproduct of the process. By harnessing the waste heat, the company is able to purify the brackish water even further, making it suitable for reuse.

The company’s patented technology uses forward osmosis (FO) as an alternative to reverse osmosis (RO) which promises 80% lower electricity consumption and 79% lower CO2 emissions. Waterwhelm are currently at pilot plant stage and will be scaling up to commercial size later in 2023.

Waterwhelm’s projections and life-cycle assessments indicate that the technology’s implementation will lead to a cumulative saving of over 5.3 megatonnes (Mt) CO2e to 2030. Based on an Impact Forecast report, a desalination plant (200,000 m3 per day) collocated with a wastewater treatment plant (100 m3 per day) could lead to a reduction of 764 tonnes of CO2e per year.

If Waterwhelm’s wastewater system was adopted by 2,800 wastewater treatment sites across Europe, this would yield total savings of circa 2 Mt CO2e per year. Assuming desalination plants in the UAE are converted to Waterwhelm’s technology, the total CO2e savings per year would be circa 9 Mt CO2e.

Rigid wave energy converters and sea defences don’t do well in a natural, fluid environment. However, WaveX are developing a solution that can mimic nature by installing lightweight, flexible structures within the seabed to convert and dissipate wave energy using nature’s processes.

The company uses a novel nature-based solution to install its devices, learnt by copying the stargazer fish. The solution is simple and relies on only a small jet of water into the seabed, enabling our devices to be self-installing and remotely retrieved. By doing this, the solution can protect the coastline by installing sandbars, and can absorb nearshore wave energy safely from the seabed, replacing the need for costly metallic structures that don’t belong in this type of environment and become damaged by storms.

Using these nature-based solutions will allow WaveX to remove over 100 million tonnes of CO2 annually from the global emissions base, by offsetting production of electricity from coal and gas plants traditionally used to stabilise the grid. Ocean energy is a much more continuous source of energy than wind or solar, and so its converters producing cheap energy will allow this balancing to occur easily without the need for battery storage or other storage options. WaveX aim to produce low-carbon electricity with a levelised cost of electricity of £0.04 per kWh.

Windswept Energy is developing a wind power solution in the form of kite turbines. According to studies from Delft University of Technology, Munich Technical University and the University of Strathclyde, using kites in wind power reduces the mass required to only 10% of an equivalent traditional wind turbine.

Unlike traditional wind turbines, they are lightweight and compact, meaning they can be transported and installed easily without the need for new infrastructure. The solution has the ability to be relocated without causing harm to the environment.

The company’s kite turbines also have the advantage of flying at higher altitudes where the wind is stronger and more reliable. This helps to overcome the variable output issue of traditional wind energy, making it easier to balance supply and demand.

Another benefit of kite turbines is their efficient blade design. The kite blades can sweep through larger volumes of air, generating at least 6 times more energy per unit of land area compared to traditional turbines. This dramatically redesigns wind energy harvesting, allowing for greater scalability and efficiency.

Overall, Windswept’s turbines lower embodied carbon (0.7 grammes CO2e per kWh) and localised environmental impact. This allows for faster, flexible and lower cost installation, greater scalability and increased reliability with rapid on-ground maintenance.