23 minute read

Press Releases › › › › › › › › › › › › › › › › › › › › › › ›

Welch Wins the Bid for the 2022 Trailer for a Cause, Benefiting Eagle’s Healing Nest

SAUK CENTRE, Minn. – Felling Trailers, Inc. conducted its tenth annual online auction of an FT-3 drop deck utility trailer to benefit a nonprofit organization: Eagle’s Healing Nest. A winning bid of $7,752.00 won the auction that ended at noon on August 27. The bid winner was Joe Welch of Caledonia, Minnesota.

Joe, an equipment dealer, has followed Felling Trailers’ Trailer for a Cause auctions for a few years. “This was the first auction I was able to catch before it closed. When I saw the cause, I really wanted to help support the Eagle's Nest’s ‘Promises Made, Promises Kept’ mantra. This is an exceptionally important mission they are undertaking that not only affects the people getting assistance by the entire community and the community of volunteers that assist in their cause,” said Joe. With just six minutes left in the auction, Joe placed his bid of $7,752.00, winning the bid at the close of the auction.

A week after the auction had finished, Joe and his father Jerry, an Army veteran who served from 1955-1957, made the close to four-hour drive from Jerry's home in Gilbert, Minnesota, to Sauk Centre to pick up the Patriot Blue, FT-3 Trailer for a Cause. Once at Felling Trailers, they met with Felling Trailers’ owners: Brenda Jennissen and Bonnie Radjenovich, along with Chris Senger, Felling Trailers’ Senior Material Handler, who is also on Eagle’s Healing Nest’s Advisory Board and a volunteer. Chris shared with Joe and his father how Eagle’s Healing Nest came to be nine years ago. “The Nest is run by veterans and volunteers. Many of the vets who have moved on from the Nest still come back to visit and help. We currently have two to three new vets coming to the Nest each week needing to heal, with over 100 vets calling the nest home,” said Senger. Joe shared with the Felling team that he had a proxy bid set of $10,000 and that he would be writing an additional check for $2,000 to be donated to Eagle’s Healing Nest. "This was the right trailer, the right cause. Our veterans are very important. We need to take care of them,” said Joe. "A very big thank you to you, the Felling family, and team members for all they do to help support their community. It's organizations and people like you that go beyond what is expected and give back to our communities, helping them grow and prosper. I am very glad I could be a small part of this cause.”

Joe will be using the trailer for a little bit of fun hauling his side by side, but primarily for his business, Joe Welch Equipment, selling used farm and industrial equipment. "I am looking forward to people asking what the promises made, promises kept means!" said Joe. Along with his father, Jerry, Joe's brother, Bill, served in the National Guard, and a very good friend Bob Hosch served in WWII. "It's important that we take care of our veterans however we can. Each person that steps up to volunteer and to help makes such a difference," said Welch.

The 2022 Trailer for a Cause FT-3 utility trailer was painted a custom metallic “Patriot Blue” with chrome pinstriping and bared the Eagle’s Healing Nest’s emblem along with its credo “Promises Made, Promises Kept.” Several Felling Trailers' suppliers joined to support Eagle’s Healing Nest by sponsoring the trailer build, from lighting to tires to decking. The 2022 Trailer for a Cause sponsors were Trans-Texas, PPG, Dexter, Sealco, Peterson, Industrial Wood (Blackwood), Demco, Pacific Rim, and Metal Crafters/Flexco. Felling Trailers wanted to generate awareness about the invisible wounds of war that our veterans carry and how Eagle’s Healing Nest helps them restore their honor, dignity, pride, and purpose. The online auction ran for six days, from Monday, August 22nd at 7 am through Saturday, August 27th (during Eagle’s Healing Nest’s Annual Nest Fest), at noon CST, ending with Welch’s winning bid of $7,752. One hundred percent of the $7,752, plus Welch's additional proxy bid for a total of $9,752, will benefit Eagle’s Healing Nest! ■

Pictured above with the 2022 Trailer for a Cause, FT-3 utility trailer is (from left to right) Chris Senger, Brenda Jennissen, Jerry Welch, and Joe Welch.

Photo submitted by Felling Trailers.

Continued on page 60

About Eagle’s Healing Nest

Eagle's Healing Nest - Healing Veterans, Soldiers, and Families from invisible wounds of war from the inside out! A promise to one and a need of many was what created the vision of "Eagle's Healing Nest." The "Eagle" represents the past, present, and future military strength, independence, pride, and honor. The "Nest" is full of meaning, such as home, family, brotherhood, safety, and security. The "Hands" cradling the Nest represents the many that will wrap their support and give services to the veterans and military members to help reintegrate them back to their families and into their communities.

It is the vision and hope to never have those who served in our military to live in darkness but to bring them into the light to soar and fly free. To help restore the honor, dignity, pride, and purpose each deserves.

Founder Melony Butler created the Nest to be a place of peace and healing for veterans struggling with a host of issues ranging from depression, anxiety, PTSD, decades of homelessness, to addictions of many sorts. Veterans come to the Nest to heal with honor from the invisible wounds of war and time of service. Eagle's Healing Nest is located in Sauk Centre, Minnesota, on 124 acres with 24 buildings. Originally Minnesota Home School for Girls, a veterans' healing center came to life out of an old dormitory. Melony opened the Eagle’s Healing Nest in 2012 with two functional buildings. She stated, "We will build the Nest one branch at a time until it is complete! A place to call home and a place to Heal with Honor!" Since that time, with donations from various organizations, veterans, and volunteers contributing what they can, they have been able to renovate 21 of the 24 buildings on site. When the last of the buildings is complete, the Nest will be able to house 180-200 veterans, service members, and their families.

For additional information about the Eagle’s Healing Nest, visit www.eagleshealingnest.org.

About Felling Trailers, Inc.

Felling Trailers is a family-owned and operated Full Line Trailer Manufacturer located in Central Minnesota. Started in 1974, Felling Trailers, Inc. has grown from a small shop to a factory and office complex that today covers over 349,000 square feet. Felling’s pride and differentiation is its customized trailer division. Its engineers utilize the latest industry-leading design techniques, and its experienced metal craftspeople use cuttingedge technology to turn its customers' conceptual trailer needs into a tangible product. Felling has been providing innovative trailer solutions to the transportation industry for over 45 years. Felling Trailers' current capabilities allow them to provide a high-quality product that is distributed across North America and internationally. Felling Trailers, Inc. is an ISO 9001 Quality Management System Certified company, WBENC-Certified WBE company, and an Equal Opportunity Employer.

For more information, contact (800) 245-2809, sales@felling.com, or visit them on the web at www.felling.com. Follow them on Twitter (@FellingTrailers), Facebook (Felling Trailers, Inc.), and Instagram.

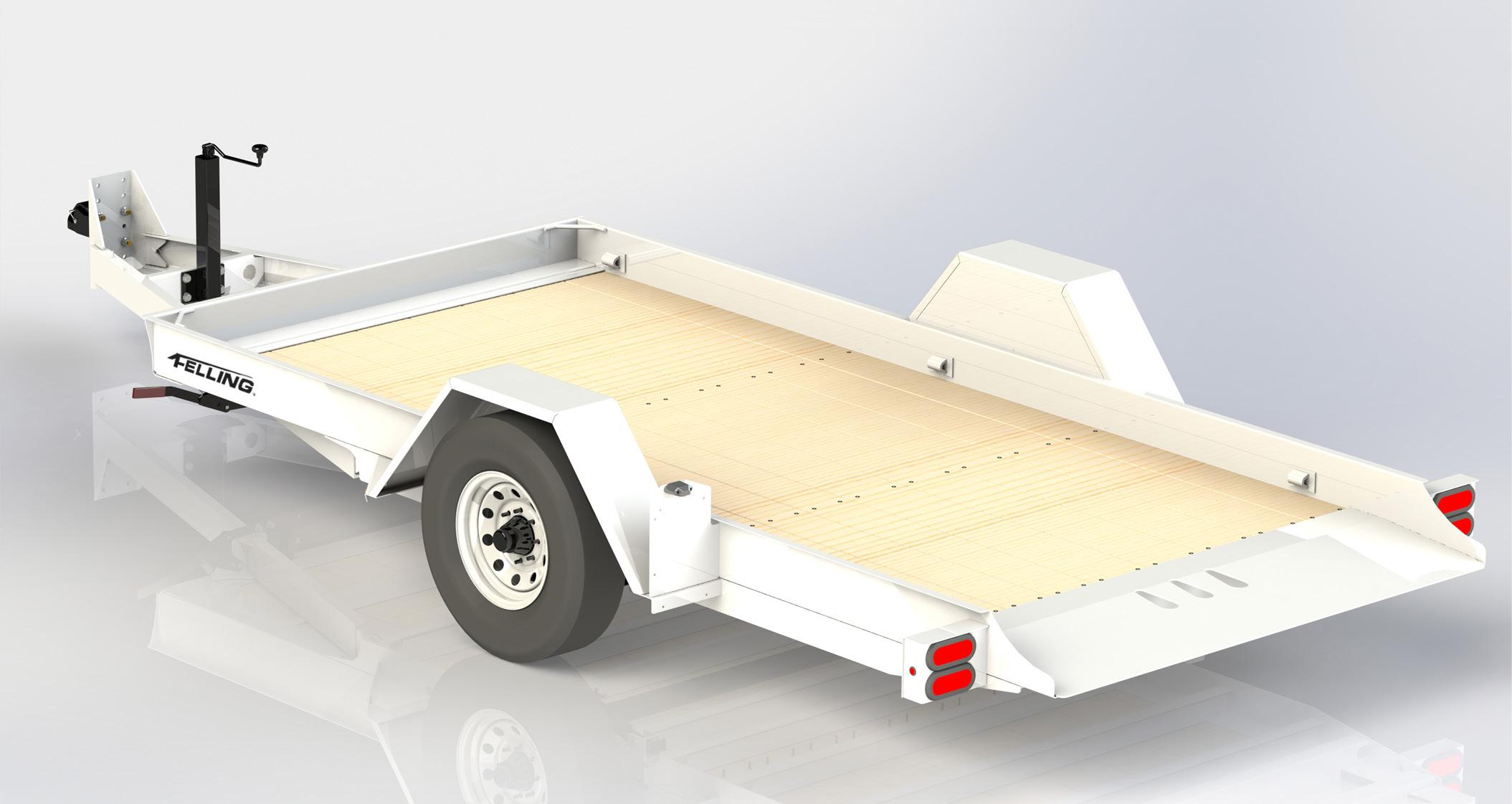

Pictured above is the 2022 Trailer for a Cause, FT-3 utility trailer. Photo submitted by Felling Trailers.

Felling Trailers’ Pan “Gravity” Tilt Trailers Receive Design Modifications

SAUK CENTRE, Minn. – The Felling Trailers’ drop-deck Pan Tilt model has undergone design modifications to increase operator ease of use and safety. The Pan Tilt is a gravity tilt trailer, using gravity and a center pivot point for tilting the trailer bed. Felling’s engineering team recently reviewed the Pan Tilt’s design looking for ways to improve operator ease of use along with production efficiencies. Modifications have been made to the Pan Tilt's locking mechanism, lighting, license plate mount position, and location.

The tilt locking mechanism is the most notable of the modifications improving the production process, flexibility to function with optional features, and most importantly, operator ease of use. The previous locking mechanism was a purchased part that required modification and multiple latches dependent upon a trailer build's selected features, power up/down, or a toolbox, as it was mounted on the front of the trailer. "The goal was not to have a longer hitch length if they (the end-user) optioned cylinders (power up/down) or an extra latch for a toolbox, making the base design more modular, streamlining the manufacturing process,” said Felling Trailers’ Engineering Team Lead, Cathy Voge. The new locking mechanism is located on the front roadside of the trailer, operating as a lever that releases a lock bar located under the front deck frame. All the components for this locking system are sourced internally, improving fit and function.

Modifications completed with an emphasis on production efficiencies were lighting and the license plate mount. Lighting modifications reduced the number of weld components needed, replacing the front marker lights and mounting plate with bullet lights that mount into the hitch channel. The bullet light mounted into the hitch channel also provides better wiring protection. The license plate mount on the pan tilts is utilized across other Felling tilt deck lines. This style mount prominently displays the license plate without obstruction from the taillights or cargo being transported, promoting operator and towing safety.

To learn more about the Pan “Gravity” Tilt model line or other Felling Trailer solutions, visit www. felling.com or call (800) 245-2809. ■

About Felling Trailers, Inc.

Felling Trailers is a family-owned and operated Full Line Trailer Manufacturer located in Central Minnesota. Started in 1974, Felling Trailers, Inc. has grown from a small shop to a factory and office complex that today covers over 349,000 square feet. Felling's pride and differentiation is its customized trailer division. Its engineers utilize the latest industry-leading design techniques, and its experienced metal craftspeople use cutting-edge technology to turn its customers' conceptual trailer needs into tangible products. Felling has been providing innovative trailer solutions to the transportation industry for over 45 years. Felling Trailers' current capabilities allow them to provide a high-quality product that is distributed across North America and internationally. Felling Trailers, Inc. is an ISO 9001 Certified Quality Management System Company, WBENC-Certified WBE, and an Equal Opportunity Employer.

For more information, contact (800) 245.2809, sales@felling.com, or visit them on the web at www.felling.com. Follow them on Twitter (@FellingTrailers), Facebook (Felling Trailers, Inc.), and Instagram.

Pictured above is the FT-7 T-1 pan tilt trailer. Photo submitted by Felling Trailers.

SAUK CENTRE, Minn. – The Felling Trailers’ Utility Cable Reel “R” series model lines have undergone design modifications to increase operator safety and ease of use. The most significant update to the model design is the auto-locking reel bar system. The auto-locking reel bar system eliminates the use of pins and brackets; it now utilizes a locking plate system. The new reel design with the auto-locking system debuted to the Utility/Telecom industry at the 2021 Utility Expo in Louisville, Kentucky. The R series product line offers payload capacities ranging from 1,740 lbs. to 13,520 lbs. All models have the capability to load up to a 120” diameter reel.

Enhanced operator and transport safety, the auto-locking reel bar system's locking plates automatically open when lowering the reel to the ground for unloading. As the reel is loaded and raised, the locking plates automatically close to contain the reel bar. Once the reel is raised to transport position, spring-loaded pins automatically lock the slides into place. When the pins lock, they provide visual validation to the operator that the reel is properly locked for transport. A green marker on the spring-loaded pins is only visible when the reel bar is properly secured. The green indicators can be viewed from the rear-view mirrors of the tow vehicle, making transporting conduit, fiber optic cable, inner duct, and many other reel-mounted materials a safe and secure experience for any operator.

The new R series design was released into production in fall 2022 and will reach full production by the first quarter of 2023. Solid and reliable, Felling’s R series continues to offer a broad selection of options and features to ensure the trailer is built to the spec that utilities/municipalities need for their applications. “These are quality-built trailers that provide the versatility and functionality that utility workers need for transporting, deploying, and retrieving material," said Felling Trailers Utility & Telecom Product Specialist Mark Rapp.

To learn more about the Utility Reel model line or other Felling Trailer solutions, visit www.felling.com or call (800) 245-2809. ■

About Felling Trailers, Inc.

Felling Trailers is a family-owned and operated Full Line Trailer Manufacturer located in Central Minnesota. Started in 1974, Felling Trailers, Inc. has grown from a small shop to a factory and office complex that today covers over 349,000 square feet. Felling's pride and differentiation is its customized trailer division. Its engineers utilize the latest industry-leading design techniques, and its experienced metal craftspeople use cutting-edge technology to turn its customers' conceptual trailer needs into tangible products. Felling has been providing innovative trailer solutions to the transportation industry for over 45 years. Felling Trailers' current capabilities allow them to provide a high-quality product that is distributed across North America and internationally. Felling Trailers, Inc. is an ISO 9001 Certified Quality Management System Company, WBENC-Certified WBE, and an Equal Opportunity Employer.

For more information, contact (800) 245.2809, sales@felling.com, or visit them on the web at www.felling.com. Follow them on Twitter (@FellingTrailers), Facebook (Felling Trailers, Inc.), and Instagram.

Pictured above is the FT-8 R trailer with optional galvanized finish. Photo submitted by Felling Trailers.

Stillwell – More Than Just Jacks

BURNSVILLE, Minn. – Started in 2006 in Bloomington, Minnesota, Coin, Inc. d.b.a Stillwell Jacks began offering its flagship Atlas hydraulic trailer jack. Since then, Stillwell has grown its product offerings to better serve the trailer manufacturing and dealer community. In accordance with its growth, Stillwell Jacks reincorporated under Stillwell, Inc. in January 2021.

To align with the company’s diversification, Stillwell removed the “Jacks” from its name. The re-branding project began in 2021 and is working its way through both physical products and company publications.

Today, Stillwell operates as a multinational corporation with domestic and international manufacturing. In addition to hydraulic jacks, Stillwell offers a full hydraulic suite including cylinders (welded, tie-rod, telescoping), hoses, adapters, and manifolds. The company’s facilities include: › Burnsville, Minnesota – Hydraulic cylinder and jack manufacturing

› Fort Worth, Texas – final assembly and distribution

› Cleburne, Texas – steel fabrication and dump trailer hoists ■

About Stillwell

Stillwell, Inc. is a family owned and operated hydraulic and steel solution manufacturer. Started in a garage with one man and an idea, the company has grown to 3 manufacturing facilities in multiple states. Stillwell’s brand value comes from its relentless passion for innovation; always seeking to improve products and processes, Stillwell releases new products yearly.

For more information contact us at: sales@stillwellinc.com or (612) 248-1110 Or visit us at: https://stillwellinc.com.

Stillwell Opens Hoist Manufacturing Plant in Cleburne, Texas

CLEBURNE, Texas – For the last three years, Stillwell has been manufacturing dump trailers hoists in Peoria, Illinois. To better service their customer base, the company relocated its hoist operations to Cleburne, Texas. This allows for quicker transit times to the large volume of trailer manufacturers located in the states of Texas and Oklahoma. Started in December of 2021, the move was made official when the property was acquired in June of 2022.

Stillwell has made their name on the innovation of their hydraulic services and has given the same attention to their hoists. Each hoist design is Professional Engineer Stamped, FEA Tested, and all welders are Weld Engineer Certified. While the Cleburne location will primarily manufacture hoists, additional equipment has been purchased to expand Stillwell’s hydraulic cylinder manufacturing to Texas in addition to Minnesota.

In addition to hoists, Stillwell plans to expand its steel manufacturing capabilities to adjacent product lines such as fenders and ramps. “Opening this site is key for our growth. It enables us to not only make more hoists, but it gives us the flexibility to make many other products as well,” Zac Stillwell, Vice President of Operations.

Stillwell has seen year over year growth. From 2018 to 2021, the company has increased 929%. The company’s growth has not only been financial, but Stillwell has grown its employee roster to keep up with manufacturing demands. This same growth will be extended to the greater Cleburne area, as Stillwell has added manufacturing jobs and looks to expand its operations in Texas. ■

About Stillwell

Stillwell, Inc. is a family owned and operated hydraulic and steel solution manufacturer. Started in a garage with one man and an idea, the company has grown to three manufacturing facilities in multiple states. Stillwell’s brand value comes from its relentless passion for innovation; always seeking to improve products and processes, Stillwell releases new products yearly.

For more information contact us at: sales@stillwellinc.com or (612) 248-1110 Or visit us at: https://stillwellinc.com.

Stillwell employees work in its new facility.

Photos submitted by Stillwell.

Optronics’ FusionX LED Combo Lamp Features Bold Styling, Fully FMVSS 108 Compliant Even in Warning Mode

Optronics’ new FusionX LED combination stop, tail, turn, backup, and warning lights look like nothing else around and are the first of their kind to enable their brake function to override their warning function while in use

TULSA, Okla.— Optronics International, a leading manufacturer of vehicle harnesses, electronic control systems and LED lighting for the global transportation industry, announced the introduction of its uniquely styled STLW and STL FusionX family of combination stop, tail, turn, backup and warning lights. Featuring a signature “X” LED lighting array in their centers, and available in eight SKUs, the FusionX lamps are the newest members of Optronics’ popular Fusion Series combination lamps.

Before the introduction of Optronics’ Fusion Series LED combination lamps in 2014, vehicles used separate six-inch oval or four-inch round stop, tail, turn lamps, and backup lamps. Each lamp needed its own mounting hole, and these holes were made in the vehicle body panels, frame posts, docking plates, or gussets. Optronics Fusion lamps changed the equation by consolidating multiple lighting functions into a single lamp footprint, reducing complexity and cost, while maintaining structural integrity. The addition of a compliant warning light function in the FusionX was a logical next step in the evolution of the Fusion Series.

Until now, combination lamps with warning light features have not met FMVSS 108 standards, because their flashing warning lights continue to operate even when their brake lights illuminate. The dual illumination patterns of these noncompliant lamps have the potential of confusing others on the road, by presenting them with mixed signals. The issue made these lamps impractical for many vehicles, particularly those in the utility, construction and roadside service sectors.

Optronics’ FusionX LED combination lamps solve this problem by disabling the warning light function as soon as the brake light is illuminated. The warning override feature helps eliminate potential misinterpretations by others on the road or worksite and allows the FusionX to fully meet FMVSS 108 requirements. The lamps also meet the SAE J595 standard for Class 2 and Class 3 directional warning lamps.

“Optronics’ new FusionX gives fleets all of the benefits of a multifunction combination lamp in addition to being DOT compliant in all modes of operation,” said Marcus Hester, chief marketing officer for Optronics International. “Not only is this a highly functional and compliant light, but its stunning x-shaped central LED array is not only stylish, but attention getting.”

With four preprogrammed flash patterns to choose from, the FusionX STLW lamps, with their warning light, have what it takes to meet the task at hand. Their centralized x-shaped LED array serves as both a white backup light and a white, amber or alternating white and amber warning flasher with two cadences to choose from. Multiple lamps can be wired to operate flashers either asynchronously, or be connected, allowing users to achieve synchronized illumination patterns. STL versions of the lamp are also available without a warning function.

The lamps come in grommet-mount versions, as well as surface/flange-mount versions. The STLW314MSHB is also available in the STLW314MGHB grommet-mount version. The STL316MSHB is also available in the STL316MGHB grommet-mount version. The STL314MGHB is also available in the STL314MSHB surface/flangemount version. The STLW316MGHB is also available in the STLW316MSHB surface/flange-mount version.

The lamps come hardwired and ready to install. As an integrated electrical system solutions provider, Optronics is also able to configure the lamps with industry standard connectors by request. FusionX lamps are available in both bulk and polypack packaging.

The lamp’s lenses are made of tough polycarbonate material that is sonically welded and resistant to dust and moisture and is suitable for harsh operating conditions. The lamps employ a solid-state, surface-mount device (SMD) design that protects their electronics against moisture, shock and vibration. Like all LED products from Optronics, these lamps come with a no-hassle, one-diode lifetime warranty protection that will replace a lamp if even one diode fails.

“The FusionX family of LED lights was designed to be compact, highly functional and exceptionally attractive,” said Hester. “The lights specifically address multiple industry lighting needs that were not being met – and look slick doing it.”

The new STLW and STL FusionX family of combination stop, tail, turn, backup, and warning lights are available in sample form now and are expected to be commercially available for shipping in the fourth quarter of 2022.

Optronics products are available in the U.S. and Canada through the company’s extensive distribution network of more than 30,000 convenient distribution locations. Users can access individual Optronics distributor websites by simply clicking on their logo icons. For information on international sales and distribution of Optronics products, please contact Dorian Drake at (914) 697-9800, or visit www.optronicsinc.com. ■

Continued on page 67

About Optronics

As the fastest-growing vehicle lighting and harness manufacturer in the U.S., Optronics International attributes its success to delivering better value, better options and better systems to its customers. Founded in 1972, Optronics International is a premier worldwide manufacturer and supplier of branded industrial and commercial vehicular safety lighting products and premium, custom electrical wiring harnesses for commercial vehicle applications. The company specializes in electrical system and harness design and interior and exterior LED and incandescent lighting for heavy-duty on- and off-highway vehicles, armored couriers, light- to medium-duty trailers, specialized vocational equipment, transit vehicles, RVs, and marine equipment. The company’s patented USA-PLUS system provides the most advanced molded harness connections available in the market. The Optronics product catalog is among the most extensive in the industry. Optronics is headquartered in Tulsa, Oklahoma, and it has an IATF 16949-certified manufacturing facility in Annan District, Tainan, Taiwan. The company also has a plant in Winnsboro, Texas, and ISO 9001:2015-certified manufacturing and distribution facilities in Muskogee, Oklahoma, and Goshen, Indiana. Learn more at www.optronicsinc.com.

Wil-Ro, Inc. Introduces Three New Products in Q3 2022, Launches New Brand, TerraRover Overland Company

Wil-Ro Adds Two New Distributor Partners, Totaling 29 Partners Across 17 States

GALLATIN, Tenn. – Wil-Ro, Inc., a leading truck body manufacturer based in Gallatin, Tennessee, was busy in the third quarter of 2022, introducing three new products, expanding its Distributor Partner Network, and launching a new adventure trailer brand, TerraRover Overland Company. Wil-Ro’s commitment to innovation and growth is reflected in these strategic moves and sets a solid pace for the remainder of the year.

Wil-Ro Expands Flatbed and Landscape Series Product Lines:

› Liberty Flatbed – combines design features of Wil-Ro’s skirted and utility flatbeds

› United Hotshot – modular-designed cargo and equipment transporter

› Landscape Trailer – towable version of our most popular body

“Our team is excited to have released three new products that are on track to meet our growing customer needs,” said Spencer Cassady, product engineer at Wil-Ro, Inc. “We are enthusiastic about rolling out our first Landscape Trailer, as this will help us target a new market during an uncertain time when chassis are harder to come by.”

Two New Distributors / Dealer Partners – Q3 2022 include:

› Caldwell Outdoor Equipment, Desoto, Missouri

› River City Body Company, Cincinnati

These new partners strengthen Wil-Ro's reach in the Midwest, boasting a vibrant roster in Missouri, Ohio, Indiana, Michigan, and Minnesota. Wil-Ro offers financing options to all new Distributor Partners, providing exclusive financing options through a strategic partnership with Northpoint Commercial Finance.

Wil-Ro continues its strong presence at industry trade shows to stay ahead of the curve and offer new Distributor Partners special deals to combat market challenges related to supply chain and tighter budgets.

“Attending the NATDA Trailer Show, NTEA Commercial Vehicle Upfitting Summit, and other industry events provides Wil-Ro great insight into new changes and how we can best accommodate our customers,” said Cody Dieter, install team lead at Wil-Ro, Inc. “These events keep our team informed and aware of any significant OEM news.”

August 2022 marked a new milestone for Wil-Ro's innovation as the company crossed into new territory, launching an adventure trailer brand, TerraRover Overland Company. Drawing from a half-century of manufacturing excellence, TerraRover trailers were revealed as part of Wil-Ro’s booth space at the NATDA Trailer Show in Nashville. Turning heads and generating buzz, TerraRover won the award for 2022 Most Innovative New Recreational Trailer, presented by the NATDA’s Dealer Advisory Board.

The TerraRover brand is born out of Wil-Ro's manufacturing heritage, and the company operates independently of Wil- Ro, focusing on 2-wheel towable overland and tent trailers. The TerraRover Team has a busy 2022-2023 schedule, exhibiting at leading events such as Overland Expo Series, SEMA Show, and others, showcasing its high-quality trailers.

“We're thrilled to launch TerraRover, a passion project for Wil-Ro’s leadership, capitalizing on the growing outdoor adventure tourism market. We are eager to establish and grow a Distributor Network with qualified partners ready to Brave the Wild with TerraRover," said Joshua J. Coster, president and owner of Wil-Ro, Inc. and TerraRover Overland Co.

Looking ahead, Wil-Ro remains optimistic for supply chain and chassis shortages to improve later this year into early 2023. Wil-Ro will be a returning exhibitor at NTEA WorkTruckWeek in March 2023 in Indianapolis with an exciting line-up of products. ■

About Wil-Ro, Inc.

Crafted in America since 1973, Wil-Ro, Inc. manufactures high-quality truck bodies and trailers for landscaping, hauling, construction, equipment distribution, and farming, as well as outdoor adventure excursions. Wil-Ro's premier truck bodies and trailers come in a variety of standard models as well as custom configurations to fit the needs of customers and distributor partners nationwide.

Headquartered in Gallatin, Tennessee, Wil-Ro focuses on craftsmanship and people, fostering time-honored manufacturing processes to build the strongest, longestlasting truck beds and trailers in the industry.

Forged in the fires of the American spirit, Wil-Ro is American made and veteran owned. For more information, please visit wil-ro.com.

About TerraRover Overland Co.

Made proudly in Tennessee, TerraRover Overland Co. crafts high-quality and innovative overland and tent-camping trailers for people who love exploring the great outdoors. Our heritage and reputation are rooted in producing the highest quality products. Customers are the foundation of our Tribe—we’re adventure seekers ready to Brave the Wild!

Headquartered in Gallatin, Tennessee, TerraRover is American made and veteran owned. Rewrite Possible and let your journey begin at TerraRover.com.