4 minute read

June 2024 Hybrid & Electric Vehicle Corner

from June 2024 NACAT News

by NACATNews

By Curt Ward, Professor at Joliet Junior College

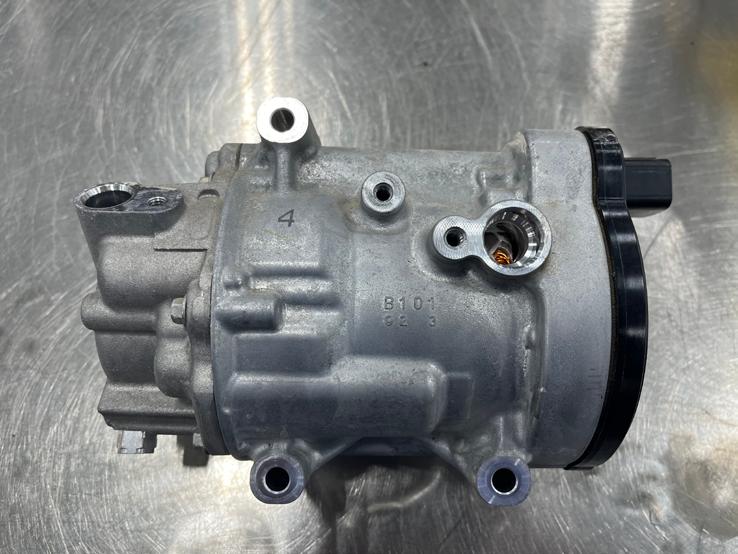

Exploring a High-Voltage Air Conditioning Compressor

As I write this article, the semester is ending, and I am looking forward to the summer instructor conference schedule. As part of our partnership with Toyota, our automotive program at JJC recently received several high-voltage AC compressors. These units are a remarkable combination of refrigeration and high-voltage electricity. One of the units has been disassembled and a demonstrator has been created. In this article, I will share some of what was learned during the disassembly.

When servicing a high-voltage air conditioning system, particularly the compressor, it is important to take all safety precautions as described by the manufacturer. This includes safely depowering the high-voltage system, verifying that high-voltage is not present, and wearing the proper personal protective equipment.

The high-voltage compressor that was disassembled is made for Toyota by DENSO in Japan. It was originally installed on a 2023 Toyota Corolla hybrid (See Figure 1 – Compressor). DENSO manufactures several different compressors for Toyota hybrid vehicles; however, the main differences are the external compressor mounting locations. The internal working components are essentially the same. The compressor can be used in a refrigeration system that uses either HFC-134a or HFC-1234yf refrigerant. It uses ND-11 refrigerant oil. ND-11 is a POE oil that has better insulating properties than PAG oil, which protects winding insulation and prevents a loss of isolation.

The rear, or “dry” portion of the compressor contains the inverter. The inverter converts the DC voltage from the high-voltage battery to AC voltage for use by the three-phase permanent magnet motor. The operation of the inverter generates a significant amount of heat. The heat is dissipated into the compressor housing via a large heatsink and a generous application of heat transfer grease (See Figure 2 - Inverter).

The core of the compressor is a permanent magnet motor and the compressor scroll. The permanent magnet motor is supported on either end with a ball bearing (See Figure 3 – Motor). The permanent magnet motor is paired with a traditional wire-wound stator. The scroll portion of the compressor is very similar to a traditional 12-volt compressor (See Figure 4 – Compressor Scroll). The combination of the scroll-type compressor and the electric motor allows the climate control system the ability to provide the desired level of cooling while minimizing the consumption of the electrical storage capacity.

One of the design features that makes this compressor unique is the location of the inlet, or low side refrigerant line. The low-pressure gas enters the compressor near the permanent magnet motor and is used to dissipate operational heat. As an added benefit, any microscopic amounts of liquid refrigerant that might return to the compressor will be evaporated by the heat absorption, which protects the operation of the compressor scroll.

The compressor has no serviceable internal parts. Any internal failure, mechanical or electrical, will require the replacement of the compressor. Recently, a similar type of compressor was found to have a catastrophic internal mechanical failure. Further investigation revealed the customer had tried to refill an empty refrigeration system with off-the-shelf refrigerant from the local parts store. A combination of a lack of lubricant and an overcharged system was the likely cause of the failure. After the compressor was replaced, the source of the refrigerant leak was identified and repaired. The system was properly evacuated and recharged and the system’s proper operation was verified. Had the vehicle been properly repaired the first time, it is likely the compressor would not have failed.

I will finish this article with the same offer I make after each of my presentations. If you are interested in getting started in the process of adding hybrid and electric vehicles to your curriculum or want more information, please feel free to reach out. I am more than willing to sit down in-person or online and share my experiences. Are you looking for a classroom textbook? Reach out to Pearson and ask for a review copy of the all-new Electric and Hybrid Electric Vehicle text that Jim Halderman and I co-authored. It is a comprehensive text covering