9 minute read

Technology

he of arrival of 3D printing is one of technology’s new hot topics: news spreading of future development into the innovation of 3D printed houses, 3D printed food and even 3D printed human organs. 3D printing is known as an additive manufacturing technology that converts a CAD (computer aided design) into a three-dimensional solid object This is achieved by digital codes being forwarded to the machine which beings the manufacturing process, instructing the layering down of thin layers of material

Fashion (comprising of apparel, footwear and accessories) is industry that could benefit from such technology given the high level of detail and precision involved to make items such as apparel. 3D printed clothing in short involves turning flexible material into clothing

Advertisement

When it was first used in fashion, the process was very slow Often it is not always the entire garment structure that is 3D printed but features such as cuffs of a sleeve or buttons

One of the first attempts at making a 3D printed piece took 7 whole days (by Dutch designer Iris Van Herpen) with the printer running for 24 hours each day The printers at the time didn’t offer flexible printing as flexible printing material wasn’t available Fortunately, technology has improved so the printing process does not take as long as 7 days, however flexibility is still a limitation restricting what can be achieved As the materials used in 3D printing are mostly plastic and metals

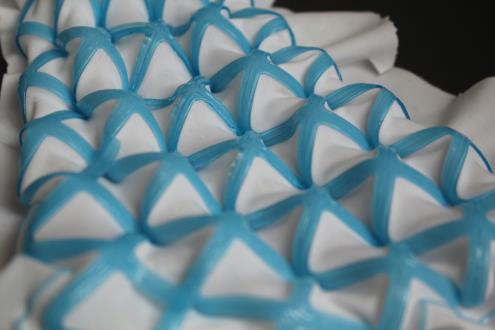

A 3D printing that has been used currently facilitates two main types of garments: rigid garments and flexible mesh which must be very fine to give a cloth-like feel and even still is not always feasible with many of the current technologies in use for 3D printing

Most 3D printed clothing will also use a selective laser sintering process (SLS) Selective laser sintering (SLS) is a powderbed fusion technology that uses a powdered material for printing The powder particles are fused on the application using a powerful laser This method offers the ability to create intricate designs and achieve a high level of detail which is a requirement key for high-end fashion (I e , clothing created for runways and red-carpet events not everyday wear)

This is why this form of printing has only been used by designers to create one-off pieces For example, it was used by famous designer and architect Julia Koerner who collaborated with the Marvel team for the Black Panther to design the costume of Queen Ramonda The brief for the costume outlined for it to appear futuristic but at the same time represent African culture 3D printing in this case enabled intricate patterns to be formed which would not only complex but timeconsuming to complete using traditional methods such as sewing

In 2015, Dabit Peleg, a young Israeli designer launched the ‘Liberty Leading the People Collection’ This was one of the first ever fashion collection in the world to be entirely 3D printed using desktop 3D printers According to the designer it took nearly 2000 hours to 3D print the entire collection This revolutionary collection is an exemplar step to promote the digitalisation of fashion

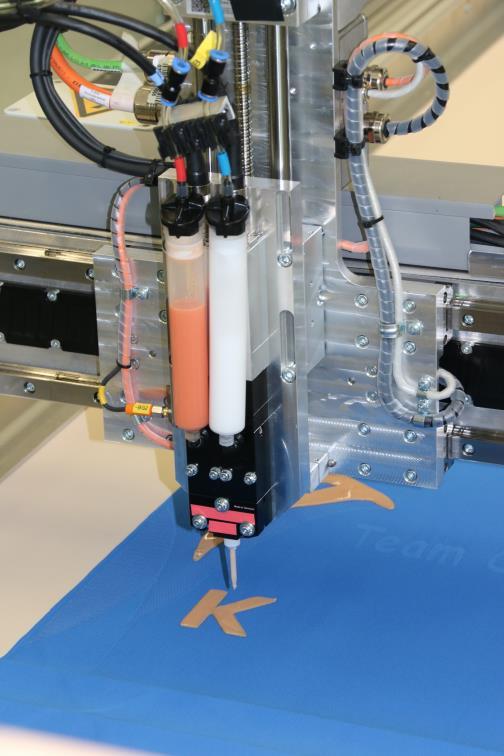

The German group, Karl Mayer, has developed a technological solution for combining warp knitted textiles manufacturing with 3D printing With the new printing solution, the textile is printed directly after it has been manufactured on the warp knitting machine

This involves machine directly communicating with the printer’s pattern system to enable targeted control A camera system combined with a pattern recognition software ensure the highest precision during positioning of the printing head on the 2 x 1 metre printing field This new 3D printing system from Karl Mayer combined the high productivity of warp knitting machines with the outstanding flexibility of additive manufacturing, hence allowing production steps to be cut

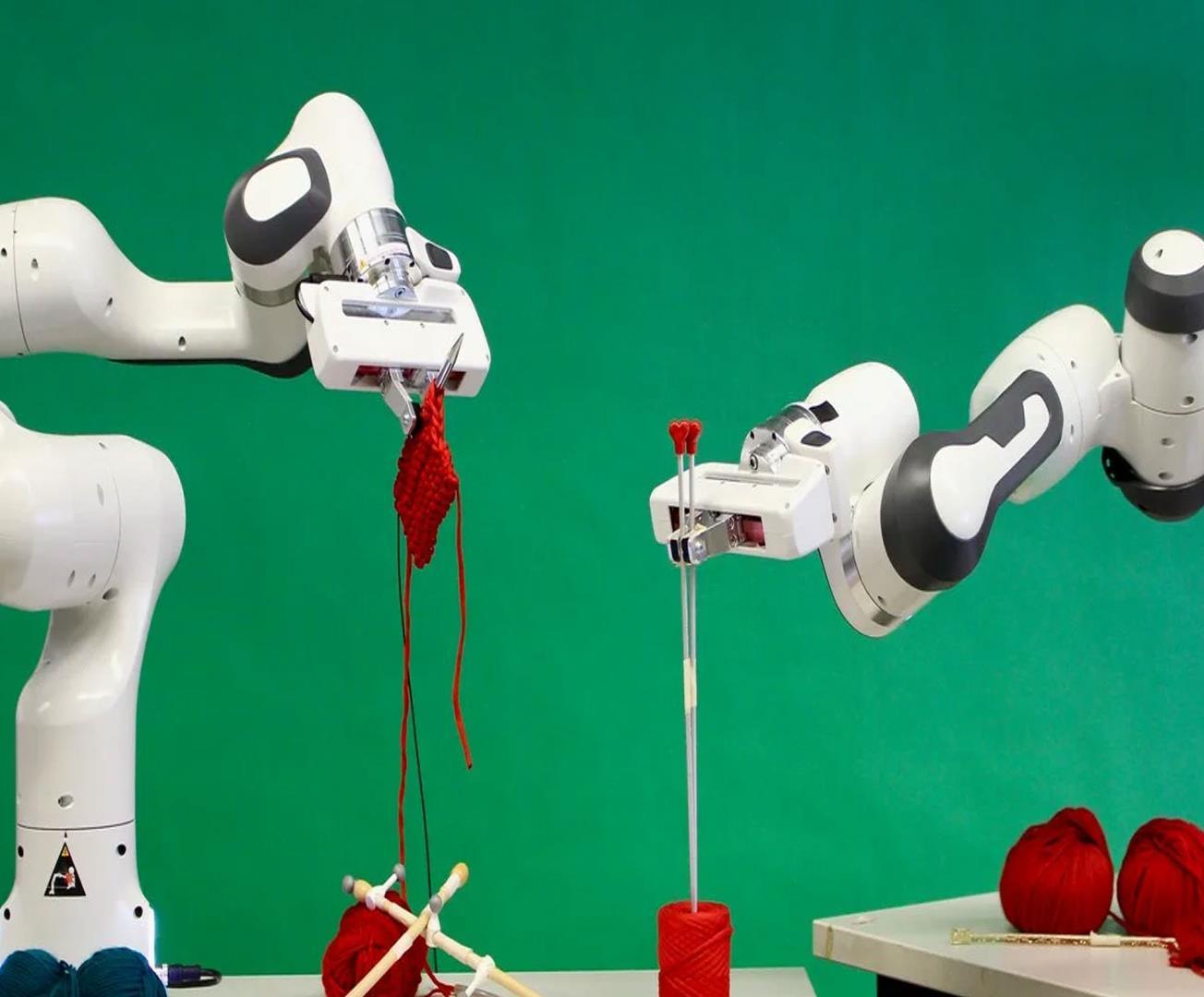

The emergence of 3D printed knitwear does seem to offer a suitable option to additive manufacturing that doesn’t use flexible printing materials The manufacturing process of 3D printed knitted fabrics is quite similar to other 3D objects Although, the machine used is where knitwear and traditional 3D printing diverge

The primary difference from additive manufacturing is that the machine is not a 3D printer that processes filament or powder through extruders, rather a knitting machine that can produce a three-dimensional garment in a single pass by uniting it thread by thread Because of this technique some industry experts argue that 3D knitted goods are manufactured using 3D printing, but instead 3D knitting Classing it a technology is its own right

In the sport sector, where high demand is placed on product performance, the new 3D printing system is ahead of the field For example, partial reinforcements such as kinesio tapes to support muscles and stabilise movement can easily be integrated in functional sport outfits using this technology

3D Knitting

Regarding the sustainability of 3D printed knitwear, a special feature of the production process is that if a thread were to break, the halfcompleted knitted part could be recycled since the knitwear is designed in such a way that it can be separated again

This means the material used can be recovered and therefore recycled And since 3D printed knitwear operates ondemand, issues such as overproduction and excess material resulting in textile waste can be avoided Since designs are created digitally (and every stich is equivalent to a pixel) patters can easily be modified and changed to customer requirements, which allows a lot of freedom with this technology

With the numerous advantages provided by 3D knitwear, the question remains as to why it is not yet increasingly available in stores Though it's clear with an additive manufacturing as mentioned previously, the material is probably the biggest obstacle- which is why 3D knitwear is being resorted to The materials compatible with a 3D printer are mostly plastics such as ABS, PLA or currently very popular TPU While they can be used to create stretchy, movable 3D objects, they don’t replicate the soft, comfortable texture of fabric best suited to apparel

And even though most of the conventionally produced clothing is in fact made from synthetic polymers (I e , plastic), the problem lies with the texture; fibres and threads are elastic and flowing, whereas filament is thick, hard and rigid Unlike 3D knitting, where moving threads are processed by small needles, the extruders of a 3D printer cannot produce anything comparable, in terms of fine enough details

Kniterate, a company selling compact 3D digital knitting machines has made it possible for individuals to scale one-off projects to production quantities The machine has six yarn feeders making it possible to create designs using six different colours

With Kniterate, you can create custom knitted products like scarves, beanies, shoe uppers, sweaters, dressers and more This machine is ideal for small fashion businesses and design studios, makerspaces and schools www.kniterate.com

This results in 3D printed clothing being rather heavy and the surface rough on the skin Regarding to 3D knitwear, there is the difficulty of creating digital codes for the knitting machine Which founder and CEO of Kniterate, Gerard Rubio described developing the right parameters as a major challenge, moving from the prototype to a final commercialise kniterate machine

It seems to be the case of 3D knitwear technology being in place and ready to function, but the current system is working against it On demand production, which is the principle of most current 3D knitwear manufacturers, completely contradicts the market flow The fashion market is currently based mass production and mass consumption Changing longestablished systems and breaking consumer habits is extremely difficult as this is requiring not only a technological change but a social change It helps to explain why many up-and-coming sustainable companies specialising in on demand production and customisation face a major barrier to entry

In terms of production costs, 3D knitwear is not at the stage where it can compete with conventional clothing due to low market compatibility Hence it is within the luxury segment in terms of price, within the confines that customers are willing and able to spend a lot for personalisation, sustainability and quality

Despite the limitations of 3D printing, experts are confident that it will play a greater role in the fashion industry in the future and that novel technologies will revolutionise it

Circular textile printing

Johanna Nissen Karlsson, former track and field runner turned entrepreneur She brought the competitive mindset of an athlete and the desire to contribute to change when she started Vividye with her friend Gustav Larsson-Utas and researcher Romain Bordes in early 2020

Vividye is an innovation which allows textile print to be removed without damaging the quality of the fibre This has been achieved by developing a pretreatment that is made to chemically respond to a removal solution The removal solution is key to this innovation, making the reuse of the textile possible The primary benefit of this technology is circularity as by enabling further reuse of textiles this offers rebranding and redesigning of garments

Vividye technique is still small-scale and under development The company’s vision for the near future is to scale up and become a market leader in circular textile printing Vividye has so far collaborated with brands such as Swedish fashion brand Gina Tricot to release a Capsule collection- the first ever removable print

Virtual Fashion design

The Virtual fashion design has increasingly become used the fashion industry among companies and independent designers Recently in particular, due to its ability to allow designers to continue to develop remotely (I e , during the Covid-19 pandemic); but some have been using it long before it was a necessity because of its benefits regarding sustainability

Using virtual reality (VR) fashion software gives designers the opportunity to create a pattern, sew and apply any functional or decorative details and change the fabric of an item

Once a designer has built their garment in 3D, they can try it in different sizes, have their 3D avatar walk to see how the garment moves and render high quality images The technology is being used by brands of all sizes and markets Early adopter were Emilio Pucci, Moschino and Helmut Lang

For a brand like Pucci who use an array of prints and intricate details, they have praised this new process for allowing them to reduce samples by being able to make decisions and see changes in real time in 3D The company reported to have cut 30% of their time and costs due to developing designs virtually

Currently, Hugo Boss is the only large brand to pursue 3D sampling, using its own technology for virtual catwalks Tommy Hilfiger also aims to use 3D design for all design processes- from sketches to sampling to the showroom

Since 2015, outerwear and sportswear have been simulated with Hugo Boss’ 3D software, and more recently in 2017 the classic men's and women's outerwear lines followed suit

Concerning physical samples, eliminating them all together is huge step for any brand to take as the value of seeing a design in person is significant Relying on 3D virtual images instead of something physical is a concept that requires a great deal of trust

For many brands they will be interested in a reduction of physical samples, whether small or large as a first step forward, to allow for the use of 3D samples to be implemented, faster and more sustainably

Artificial intelligence is also predicted to play a role in future of sustainable fashion The analysis of huge amounts of data from social media, eCommerce and smartphone feeds could, if respecting user privacy and data protection policies could make it possible to predict buying decisions and anticipate purchases and thus reduce overproduction Examples of such efforts to predict buying behaviours are evident on the roadmaps of companies such as Zalando, Amazon, Hugo Boss and others

Virtual dressing could potentially improve sustainability in the fashion industry Mobile body scanning, paired with virtual try-ons, could more accurately determine whether a garment fits or not And as a result, decisions could be made more selectively without having to purchase multiple sizes to try on and send back

While it is not yet clear when and if 3D samples will completely replace regular samples, they can certainly save time and money during the brainstorming phase whilst allowing companies and designers to be selective about which pieces, they want to bring to life

AI has already been tested by handful of upscale retailers such as Nordstrom other department stores to improve the fittingroom experience for customers With the use of a “smart” mirrors, customers can get suggestions on what to pair certain items with (e g , it may suggest jeans to go with a top the customer is trying on) or even show how items will fit you without having to physically undress and put the on

This kind of technology is of great advantage to physical stores both to increase their competitiveness alongside online rivals such as Amazon but also collect data about customers- this is given that customer privacy is protected Of course, there are weary customers when new tech is introduced but:

For customers who have purchased online this could reduce shipping emissions for returns (increasing sustainability within supply chains)

Essentially trying on a garment is comparable to exchanging data: a consumer has certain measurements, and so does a garment But only recently has the way in which we exchange and match these measurements is no longer to try on multiple sizes nonprofit Center for Democracy & Technology