1 minute read

GENERATIVE DESIGN

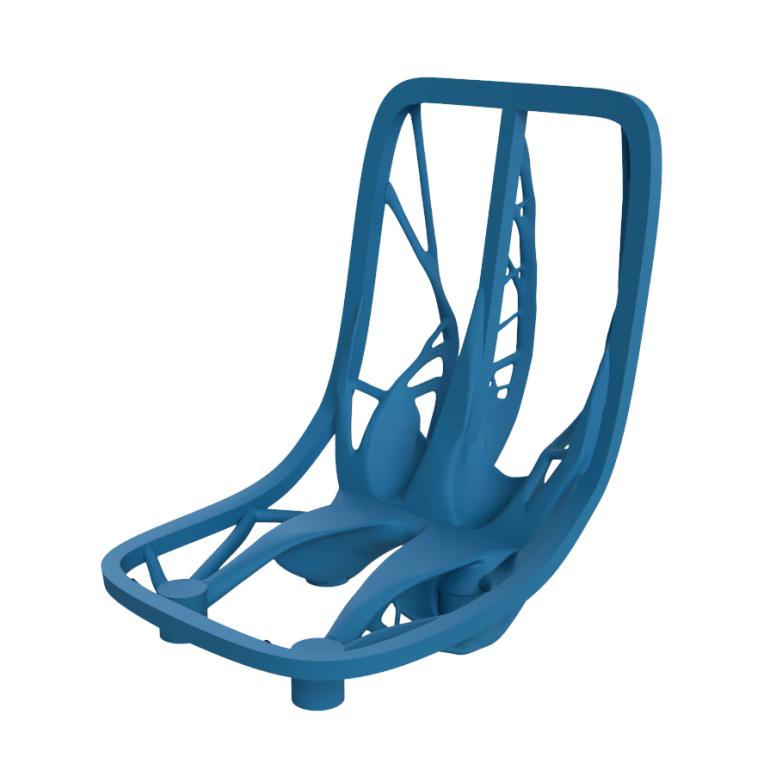

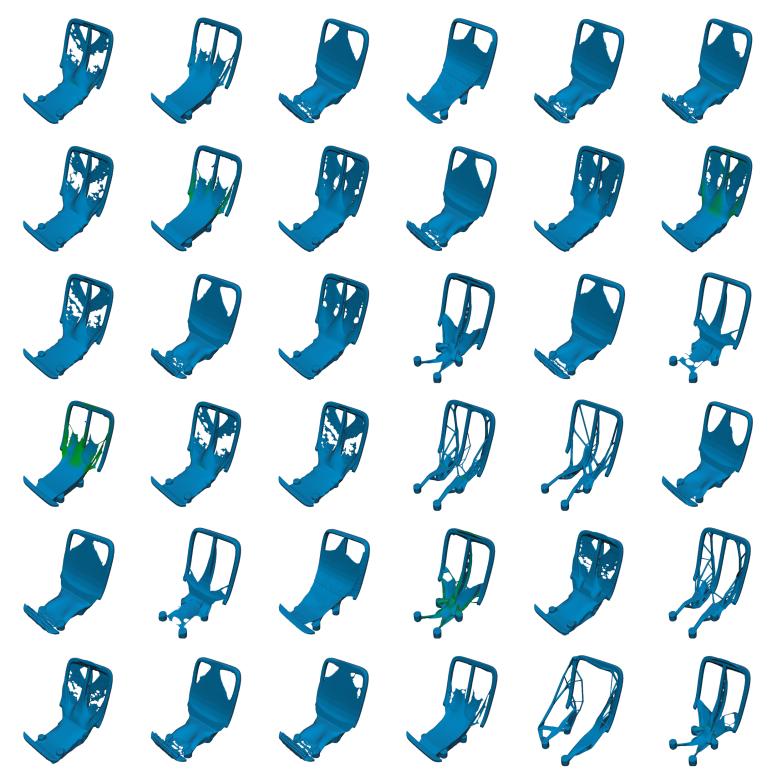

The design of the structure of the chair based on loading scenarios and the thermoplastics we planned to use dictated by Autodesk Fusion 360 Generative Design suite. Over a 100 suitable designs were churned out by the algorithms reckoning traditional print parameters and printing logic based on Z-discretization and 2.5D-Printing. However, when seen from a hybrid-manufacturing standpoint, the printing strategy becomes easier and the print more plausible. We can take advantages of Hybrid Manufacturing by printing faster using a higher resolution while relying on milling for the final surface finish. Finer details or tolerances can be attained through the subsequent milling. Moreover, designs which require a lot of support material can be printed as these can be milled out in the post-processing stage, thus widening the design possibilities for additive-manufacturing by allowing overhangs.

Advertisement