1 minute read

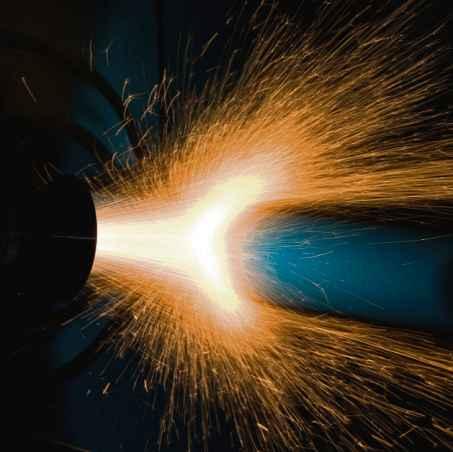

METALLISATION USPSTEELS

Dudley thermalspray equipmentmanufacturerMetallisation hasits eyes firmly set on freshgrowthasit enters itssecondcentury in business in the BlackCountry.

Thecompany in Peartree Lane,which currentlyemploys 45,now hasadetailedstrategic plan in placewithavisionto grow thebusinesstoachieve annual turnover of £18million to £20m by 2024

From itsstrong historyinthe supply of corrosion protection equipment,its customerbase is increasingly usingMetallisation’s products forengineering coatings,whether it is forsteel coatings appliedbyarc or flame equipment throughtoceramics andcarbide coatings that are appliedbyplasma, high velocity oxygen fuel or lasercladding equipment

Itseasytouse robust andreliable systemsare becoming a naturalchoicefor themanyusersaroundthe world

Plan

Metallisation underwenta management buyout 2014 and in 2019,aftercompleting therepaymentofalarge part of the financing, thedirectors completed astrategicreviewofthe business andput in placethe strategic plan

Theplanwas broken down into stages to allow fortargeted implementationofthe changes over aperiod, this included thestrengtheningofthe senior management team, andtargeted growth from development of new markets.

To assist with theplanned growth thecompany developeda newsales process, implementing acustomerrelationshipmanagementsystemand employing an external salesprofessionalto trainand develop theMetallisation salesteam.

Much of theinitial strategic workwas carried outbythe boardofdirectors, ledbymanagingdirectorStuartMilton, underthe extremeeconomicclimate of Covidand Brexit

Thecompany’s missionisto provideexcellenceinits products, supportand innovationto expand thebenefits of thermal spraytechnologyfor itscustomers.

Theequipment it supplies is supportedbythe technicalservice team, both in theUKand globally Metallisation constantly develops itsproductsand technology.

Thecompany is proudofbeingatthe forefrontofimproving technologicaladvancesand one of itscorevaluesistocommit to andinvestand grow research anddevelopment. In orderto achievethisthe companyisinvestingaround£250,000 each year in research anddevelopment

It has12per cent of itsfull time stafffocusedpurelyon R&D.

Thecompany hasbeenonthe same site for100 yearspositively contributing to thelocal economy

During theSecond WorldWar it manufactured components for Spitfires.

It waswiththe same senseof communityspiritthatthe company assisted at thestart of theCovid pandemic in 2020 by partnering with anotherDudley business –Thomas Dudley –to source andproduce masksfor theNHS

Thepandemicpresented arealchallenge forgrowingsteel stockholder USP Steels.

It wasthe firstmajor hurdle forthe companyonGibbons Industrial Park, Kingswinford,which wasformedin 2016 andhas sincegrown to employ 38 in supplyingstructuralsteel flat rolled products

USPSteels managedtooperate as effectivelyaspossiblethrough clever staff rotationstominimise Covidrisks yet maintain itsdespatchestomeetcustomer demand

It wassupplying many keyNHS contractsand it wascriticaltooffer an improveddeliveryservice to help USPstarted despatchingonweekends andexpandedoperational hoursto24/7 to help achievethis.

Reinvestment

Thesignificant growth createdincreasedprofitability andowner Glyn Costigan wascommitted to reinvestingthese profits back into thebusiness throughthe acquisitionofa newfouracre site in Kingswinford

Thetotal projectinvestmentwill be about£10 million.

Thelandwas purchasedand plans were submitted fora brand-newstate of theart purpose-built facility

Thenew facility boasts 40.000 sq ft of stockpace(allowing for7,500 tonnes of steel)

It involves ahugeincreaseonUSP’s current20,000 sq ft (2,200tonnesof steel) at itsexistingsite.

Thenew facility will be able to facilitateabout 60 office staffallowingfor future growth andemploymentopportunities.

Thenew site boasts afree flow workingenvironment to help create adifferentworking environmentmovingaway from thetraditional setupoftypical office layouts.

With breakout areasand multiple