9 minute read

Hamburg Smelter - Innovating for the good of future generations

In Copper Worldwide Vol 11 No 2 issue (pp 8-9), Phillip Mackey provides a detailed review into the history and operation of the outstanding Aurubis Hamburg copper plant

To the question “How do you become one of the best-run plants in the world?” the answer given by any Smelter Site Manager today is invariably “Good design in all plant areas, excellent operations and maintenance with very skilled supervisory and operating personnel.” The Aurubis Hamburg Primary Smelter, admirably fits this description. Reference has been made in these pages on the factors described by Arie de Geus in his book “The Living Company” as influencing the overall strength of an enterprise and the characteristics of a truly successful company. Aurubis, formerly Norddeutsche Affinerie, also fits well into this category and has done so for over 150 years.

Advertisement

In the beginning

The company’s history dates back to 1866 with the founding of Norddeutsche Affinerie AG and consolidation of the early smelting and refining facilities originally located at Elbstrasse in Hamburg. The plant was moved to the more spacious areas on Peute Island in the Elbe River in 1908 - the present location - accompanied by a number of plant expansions.

The history of the Hamburg plant features a number of very significant metallurgical innovations and milestones - too numerous to cover them all here except to note a few key ones - and a winning culture that strives to be the best, starting in the late 1800s. For example, in 1876 Norddeutsche Affinerie was the first company outside of the United Kingdom to install the then new electrolytic copper refining process that had been pioneered at Pembrey in the UK in 1869. The Hamburg plant was similar but somewhat larger compared to that at the Pembrey facility. Hamburg later expanded the tankhouse considerably and today it is one of the largest in the world. Copper electrorefining was perfected at Norddeutsche by Dr. Emil Wohlwill. He also invented a new process for gold and silver, an approach still used to this day. Dr. Wohlwill also experimented with reagent additions to the copper electrolyte and was the first to use chloride additions to help smooth out the copper deposit. All refineries today worldwide continue to use chloride additions, and still follow the main principles originally developed at these two plants.

Early plant

Facilities were soon in place to also treat copper scrap in addition to copper concentrate feed, and a lead smelting plant was also built. In the late 1930s, the annual capacity of the plant was about 95,000 of electrolytic copper and 36,000 tonnes of lead. By-products included gold, silver, nickel, tin, bismuth, cobalt and a number of metal salts. An acid plant was installed in the 1930s and was one of the first acid plants installed in a smelter anywhere in the world. Following rebuilding after World War 2 - bombing had destroyed parts of the plant in 1944 - Germany experienced huge economic growth and the Hamburg plant undertook a number of expansions.

By this time, copper concentrates sourced from all over the world were roasted in a number of multiple hearth roasters and smelted in a reverberatory furnace, producing a copper matte containing about 45% Cu. This matte was converted in one of two Peirce-Smith converters. Blister copper was processed to anodes for the copper refinery. This facility had also been expanded, and due to space limitations, a number of cells were built on the second floor of the tankhouse - likely the only plant with such an arrangement.

The flash era

In the late 1960s, with the plant eying a further expansion to meet the growing copper demand, alternative smelting technologies were evaluated - including electric furnace smelting of roasted concentrate and Outokumpu (now Outotec) flash smelting. At this point there were over eight new flash furnaces operating worldwide and this technology was wisely chosen for Hamburg.

The flash furnace was built in a new area of the site. The plant, commissioned in March 1972, had a design capacity of 400,000 tonnes of 27% Cu conc. /yr, or a smelting rate of 50 t conc. /hr, producing 60% Cu matte. The facility included a 2 MW (nominal), 10 m dia. electric furnace for cleaning the flash furnace slag; converter slag was returned to the flash furnace. A new double contact (double absorption) acid plant was also built - likely the first or one of the first double absorption acid plants at a copper smelter. Concentrate receipts were handled at the nearby port and brought to the plant by barge. Blending facilities were also improved.

In operation, copper concentrates were dried in a new, 30 m long kiln dryer fired with natural gas, with dry concentrate conveyed to storage bins located above the flash furnace. Initially the flash furnace operated with 540 oC preheated air and the reaction shaft was cooled - as at many flash furnaces of the era - with a falling water film. Later oxygen enrichment was introduced and shell cooling elements replaced the water film cooling. Off-gases were cooled in a waste heat boiler rated at 49 t steam (60 bar)/hr. It was reported that cleaned slag at the electric furnace contained about 0.65% Cu. Tapped slag was cast in small ladles and after crushing was used for construction and for river dikes. At the time, there were still two 4.25 m by 11 m Peirce-Smith converters installed, with one blowing, and one on standby. Oxygen enrichment to about 25% O2 was used to assist in skull and scrap smelting. Blister copper was handled in two rotary anode furnaces with natural gas used for poling. It is understood that the reverberatory furnace remained in use for some time.

By the mid-1990s, concentrate throughput at the flash furnace had been increased to 70 tonnes of conc./hr, or about 600,000 t conc./ yr, primarily by the use of oxygen enrichment supplied by a 240 t/d oxygen plant, along with a number of other plant improvements. Environmental enhancements introduced included secondary hooding on the converters and side charging at the hood for scrap, a new concentrate storage building (100,000 t capacity), improved performance of the waste heat boiler, gas cleaning

The double contact (double absorption) acid plant at dusk.

Photo: Aurubis

Aerial view of Aurubis Hamburg.

Photo: Aurubis

of dryer off-gas and also anode furnace off-gas, plus improved fugitive gas collection and control. Additional acid plant capacity was installed with overall sulphur capture at the time of over 99.3%. Water collection at the site and water treatment was also upgraded. Improvements in emission control and environmental protection had become integral at Aurubis to any proposal to increase plant throughput and anode production.

Further improvements

A new tankhouse based on the Isa system was built on a new site next to the flash furnace building in the West area of the site in 1990. The former tankhouse was closed. With a nominal capacity of 172,000 t Cu/yr. (600 cells), an additional 480 cells were soon added to bring the capacity to over 300,000 t Cu/yr.

Converter capacity was increased, now with 3 Peirce-Smith converters, 4.6 m in diameter and 12.2 m in length and fitted with automatic punching. New converter blowers rated at 52,000 Nm3/hr and 1.5 bar were also installed which greatly improved converter operation, now with two converters blowing at a time and one on standby.

Norddeutsche further expanded in the 2000s with the acquisition of number of operations in Europe including: Huttenwerke Kayser AG in Lunen, Germany in 2000, the Belgium copper producer Cumerio in 2008, the smelter in Pirdop, Bulgaria, the wire rod plants at Olen and Avellino and the speciality metals plant at Yverdon-lesBains in Switzerland. Following these acquisitions, stockholders decided to re-name the Company “Aurubis AG” - the new name having being derived from the Latin terms “aurum” for gold and “rubrum” for red - in effect, “red gold”, reflecting the extraordinary value of copper.

In 2010, it was reported the plant treated 1,079,000 t of copper concentrates (this included copper from copper scrap), and acid production was 1,052,000 t.

Environmental Senator Jens Kerstan inaugurated a 10 MW power-to-steam plant at Aurubis Hamburg with CEO Roland Harings in August 2019.

Photo: Aurubis

Current activities

At the 2016 Capital Market Day presentation on the occasion of its 150 year Anniversary, Aurubis highlighted a number of accomplishments and further plans. These were further elaborated in the Capital Market Day 2018 presentation which also detailed the Vison 2025 strategy. A proposed bath smelting plant as well as the related copper leaching and electro-winning plants at the Hamburg and Olen sites was discussed, having a capex level of EUR 320 million. This project was later shelved following the acquisition of the Metallo Group of Belgium in June 2020. This acquisition was seen as a key component in the implementation of Aurubis’ multimetal and recycling strategy. For the fiscal year 1 October 2019 to 30 September 2020, the Hamburg facility reported the production of 384,000 t of cathode copper and the treatment of 1,026,000 t of copper concentrates.

Environmental control at the Hamburg plant is excellent. For example, sulphur dioxide emissions at 4 kg of SO2/t of copper produced are amongst the lowest in the industry. Similarly, emissions such as copper in dust (13.6 g/t of copper produced) are also very low. A program to fully collect low level fugitive gas emissions from smelter roof opening is to be completed by 2023.

Innovation continues

The Hamburg plant has a long history with many successful “firsts” in the industry. As this article was nearing completion, a very significant new “first” was announced by Aurubis on 27 May 2021. At the end of May, Aurubis commenced testing the use of hydrogen as a replacement of natural gas for copper de-oxidation in the anode furnace. The technical literature in copper includes several reported laboratory tests demonstrating the application of hydrogen at the laboratory scale for the gaseous de-oxidation of anode copper, but this will be the first use of hydrogen for this purpose at a large copper plant.

When commercialised, Aurubis reported that the new process will reduce CO2 emissions at the facility by some 6,200 t CO2/yr. It is estimated by the writer that the plant will require roughly about 1,100 t H2/yr reported to be supplied by Air Liquide. Further, it is estimated that if production is by electrolysis, the hydrogen will require 62,000 MWh/yr of electricity; this corresponds to roughly 10 MWh/t CO2 saved.

The Aurubis press release noted that hydrogen generated from renewable sources is a sustainable energy source. It is considered that eventually the hydrogen for Hamburg would likely be generated from such sources to avoid carbon dioxide emissions from the hydrogen electricity requirement. Overall, a significant first step towards carbon reduction using hydrogen and another important first for Aurubis.

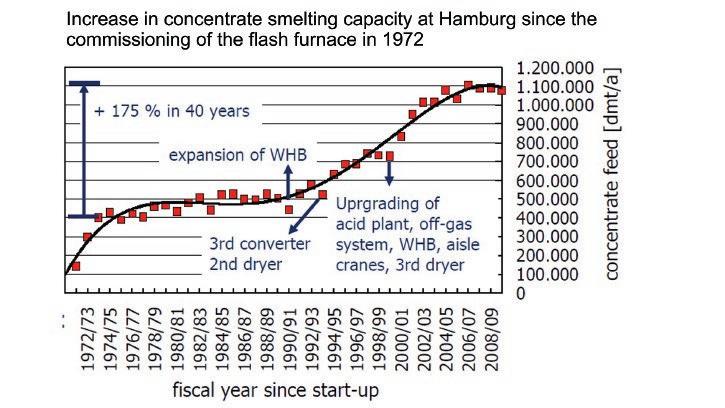

Between 1972 and 2009 a 175% increase in concentrate smelting capacity has been achieved.

Source: Aurubis

www.aurubis.com

Author: Dr Phillip John Mackey is an internationally recognised expert in the production of non-ferrous metals, especially copper and nickel smelting and refining.

References

P. Willbrandt, Operational Results of Norddeutsche Affinerie Copper Smelter, The Paul E. Queneau International Symposium Extractive Metallurgy of Copper, Nickel and Cobalt Volume II: Copper and Nickel Smelter Operations, pp 1361 - 1376, The Minerals, Metals & Materials Society (1993).

H. Wiehler, Current Status of Production and Expansion Projects of Primary Smelter Aurubis Hamburg, paper at EMC 2011.

Cu 150.0-Tradition, Expertise, Innovation, 1866-2016: The History of the Copper Group, Aurubis AG, Hamburg, 2016.

Aurubis Capital Market Day 2016 presentation, Aurubis AG, Hamburg, Germany.

Aurubis Capital Market Day 2018 presentation, Aurubis AG, Hamburg, Germany.

Hamburg Plant: Emission Facts & Figures, Factsheet February 2019, Aurubis AG, Hamburg, Germany

Environmental Protection in the Aurubis Group - Hamburg and Lunen sites, 2017, Aurubis AG, Hamburg, Germany.

Aurubis-First copper anodes produced with hydrogen, Press release, 27 May 2021, Aurubis AG, Hamburg.