7 minute read

Methanol 4-strokes by 2023

FUTURE FUELS FOR 4-STROKES

MAN ES turns its attention to small-bore engines on its journey to new fuels

For ship propulsion, “dual-fuel has come to stay” in all vessel segments, according to Thomas Hansen, head of two-stroke promotion and customer support at MAN Energy Solutions. “And that gives a general need for auxiliary power also to be delivered by dual fuel.”

He was speaking in one of the engine designer’s ‘ExpertTalks’ webinars on 30 March and highlighted 2021 as “a fantastic year for ship contracting” with 32% of their total installed power specified for dual-fuel, which he expects to climb to 75% this year.

Significantly, however, most of this power share – 23%, rising to 70% this year – is for ships that cannot use their cargo as fuel, such as container ships, products and crude tankers, dry bulk and general cargo vessels. This, he said, is “the big game changer”.

To be ready for the impact this will have on its four-stroke business, MAN Energy Solutions is “looking into all the different fuel types and analysing which may be most interesting for gensets”, he said. But already, the company has set out a possible timeline for offering four-stroke fuel options.

Hakon Juel Hansen, its promotion manager and business developer for small bore four-stroke gensets, said that at present its engines can use biofuel – such as Hydrotreated Vegetable Oil – synthetic fuel oils and methane. Next year, dual fuel methanol/diesel engines will be available followed in about 2025 by hydrogen/diesel options. In the longer term, ammonia/diesel versions will be launched (see box).

Simple and reliable

Five “crucial priorities” form the heart of its strategy for auxiliary engines, he said. They must: 5 Provide a secure electricity supply; 5 Have excellent dynamics (load-step performance); 5 Be reliable and simple; 5 Provide good combustion performance; and 5 Have good consumption figures.

Mr Hansen said that providing a secure electricity supply – “we don’t want to see a black ship at 0200” – called for reliability and thus simplicity, so “our control platform for these dual fuel engines is not a sophisticated computer [or] common rail system”. Instead, “we have chosen a very straightforward, reliable, simple conventional control strategy and engine design.”

As for genset dynamics, MAN Energy Solutions’ specialist for small bore four stroke engines Klaus Petersen referred to its experience of its 28/32 DF and 23/30 DF engines, which have been on the market since 2014. Conventional dieselonly gensets could achieve 33% load steps, he said, which is also possible with its dual-fuel versions.

When increasing power, from zero to 20% load is in diesel mode, with incremental 20% load steps up to 100%, something that he said competing engines could not achieve. “It is possible to switch between gas and diesel modes even under full engine load” and the engine can run at 110% load in both diesel and gas modes, his presentation noted.

But combustion using future fuels in a dual-fuel four stroke engine is very different from in a conventional diesel engine, Mr Hansen said. Because of parameters such as different viscosities and a lack of ‘hidden lubrication’ compared with conventional fuel, engine modifications are required.

Additional and larger injectors may be needed, for example, because of the fuels lower energy densities, and new sealing materials may be required, because “these new fuels can be very aggressive towards the material”, especially methanol and ammonia. Engine control electronics will also need upgrading to suit new combustion parameters, he said.

When it comes to consumption, Hansen emphasised his main priority, saying that although consumption is good, “it’s not best in class, but we have prioritised security of the onboard electrical power supply”.

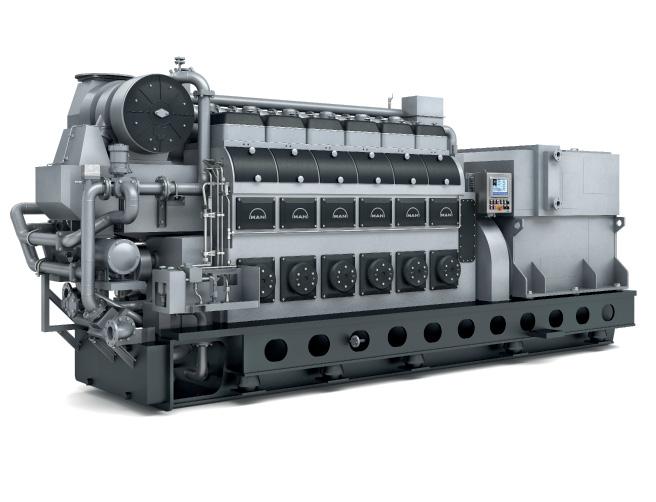

8 MAN Energy

Solutions already has experience of dual-fuel fourstroke operation, such as with the 28/32 DF genset

Future fuel options

MAN Energy Solutions already has “decades of experience” with biofuels and only minor modifi cations are needed for an engine to use it, its promotion manager and business developer for small bore four-stroke gensets Hakon Juel Hansen said.

Meanwhile, “very successful” full scale trials are being conducted with methanol fuel on a MAN L21-31 test engine in MAN Energy Solutions’ facilities in Frederikshavn, Denmark, where different combustion cycles are being evaluated. “We are moving very fast forward with the methanol version of our engines”, Hansen said, and “current findings show that only limited design changes are needed”.

Hydrogen and ammonia, however present bigger challenges, not least because four-stroke engines run typically 10 times faster than two-stroke engines.

Hydrogen is more likely to be used to produce synthetic natural gas, green methanol and green ammonia than to used as fuel on large merchant vessels, he said, “so hydrogen-fuelled MAN four-stroke gensets are not immediately planned”.

Although ammonia is considered a prominent future fuel for large engines, its potential for four-stroke small-bore engines running at a higher speed “are being investigated”, he said. In particular MAN Energy Solutions is one of four companies and the University of Munich taking part in the three-year ‘AmmoniaMot’ project, which started in December 2020 with support from Germany’s Federal Ministry of Economics and Technology.

WinGD HIKES X-DF2.0 FUEL EFFICIENCY PERFORMANCE

Winterthur-based engine designer WinGD confi rmed at Nor-Shipping in Lillestrom that fuel savings achieved with its X-DF2.0 engine technology have surpassed initial expectations

Optimised engine settings on WinGD’s X-DF2.0 secondgeneration dual-fuel engine platform have achieved fuel savings of up to 8% in gas mode and up to 6% in diesel mode during recent tests conducted upon a 92-bore engine at CMD (CSSC-MES Diesel Co) in Shanghai, China.

The announcement represents a 5 percentage point reduction in fuel consumption in gas mode, compared with the 3% efficiencies that the engine designer previously supported. The Motorship notes that this is likely to reflect the engine designer’s successful operation of the engine at higher compression ratios in gas mode, which contributed to the improvement in fuel efficiency.

Otto cycle engines need to carefully maintain a lean airfuel mix to ensure it remains within an ‘operational window’, as too rich a mix can cause it to self-ignite before pilot fuel injection, (‘knocking’) while too lean a mix can cause combustion instability (‘misfiring’).

By adding carbon dioxide to the air-fuel mix, the reactivity of the cylinder charge is reduced, and the combustion speed is lowered. The Motorship has previously reported that effectively widens the operating window for Otto Cycle engines by pushing the ‘rich limit’. This would allow the engine designer to optimise the engine for lower emissions.

Volkmar Galke, Global Sales Director at WinGD told The Motorship that, following the Technology Confirmation Test, further research was being carried out into the expected savings for smaller sized engines in the engine designer’s portfolio. An announcement of the results from the trial on a smaller bore engine are expected later in Q2 2022, Galke said, but initial results suggest that the technology will demonstrate broadly similar fuel efficiency savings across the engine designer’s portfolio.

Galke noted that the increased fuel efficiencies were likely to alter the economics of specifying the solution, although payback periods were expected to be driven by underlying fuel consumption, and would be shorter for larger vessels, such as containerships.

“The improved fuel efficiencies, in addition to the methane slip reduction, make the solution look increasingly compelling for customers,” Galke added.

The iCER solution reduces methane slip by up to 50% compared with first generation X-DF engines and also enables Tier III NOX compliance in liquid fuel mode without the need of additional Selective Catalytic Reduction (SCR) NOx reduction technology.

Having first discussed the iCER technology with The Motorship in 2019 at Gastech in Houston, Galke was pleased to confirm that the first references of the X-DF2.0 are due to enter into operation in 2023 onboard two newbuild dual-fuel pure car and truck carriers (PCTC). In all, more than 60 engines with iCER solutions have been ordered.

WinGD has been heavily focused on extending the technical possibilities of the iCER solution in recent months.

In November 2021, Dominik Schneiter, WinGD’s VP of Research and Development, exclusively revealed at The Motorship’s Propulsion and Future Fuels conference in Copenhagen that had successfully lowered methane slip emissions from an Otto Cycle engine below 1g/kWh in gas mode. The technical milestone, which was achieved during a concept trial of an iCER solution for multi-turbocharger applications, represented “a record low for any lean-burning engine”, Schneiter said at the time.

8 Volkmar Galke, WinGD’s Global Director of Sales

iCER technology

The iCER technology itself consists of the extraction of part of the exhaust stream after the turbocharger. Part of the exhaust stream is discharged via a pack pressure valve, while the remainder is pre-cooled in an optional economiser, before being circulated through a Cascade Exhaust Gas Cooler (CEC).

The water from the spray cooling system drains into a circulation system, while bleed off water can be discharged directly without treatment. By recirculating a fraction of the exhaust stream, this not only reduces the reactivity of gas/air-mixture by replacing oxygen in suction air with carbon dioxide but also improves thermodynamic behaviour of the X-DF engines in terms of brake specific gas consumption, firing pressure fluctuations and emissions.