9 minute read

Power from waste

NEW POWER PACK CONVERTS WASTE HEAT TO ELECTRICITY

Alfa Laval has unveiled a new power pack capable of converting waste heat directly into electrical power

The E-PowerPack reduces fuel consumption and CO2 emissions, helping owners and operates meet marine industry decarbonisation targets.

“Alfa Laval is pursuing a wide range of technologies to support decarbonisation, both independently and with partners,” said Lars Skytte Jørgensen, vice president technology development, energy systems, Alfa Laval Marine Division.

“Fuel cells and many other innovations are in the pipeline, but the first critical step is to leverage the existing energy on board.”

Launching on 5 April via webinar, the E-PowerPack is a self-contained solution that can generate electricity from many different heat sources on board.

These include exhaust gas waste heat, which accounts for 50% of the energy from combusted fuel, but also liquid sources at lower temperatures, such as engine jacket water.

Regardless of which fuels are used, fleets can use the E-PowerPack to reduce their fuel consumption, emissions and costs.

On vessels where moving to low-sulphur fuel has created a surplus of steam, the E-PowerPack will transform the excess into a free source of power. The E-PowerPack will also be vital as energy recovery becomes key in transitioning to green methanol and ammonia.

“Savings that offset fuel costs are only one part of the picture, since methanol and ammonia are both more expensive and less energy-rich,” said Danny Ingemann, head of sales.

“For the amount of fuel they carry to be feasible, vessels will need to utilise all of the energy that methanol and ammonia contain. The E-PowerPack will be a vital part of achieving the energy balance.”

8 Alfa Laval’s E-PowerPack converts waste heat directly into

electrical power

Contract awarded for world’s biggest wind farm

Heerema Marine Contractors have been awarded a contract for the transport and installation of the Dogger Bank C offshore substation off the northeast coast of England.

The massive off shore wind farm will see the substation for phase 3 delivered by Heerema.

Owners SSE Renewables, Equinor and Eni made the award as part of the third and final phase of the Dogger Bank project, which means total energy generating capacity will be 3.6GW combined with Dogger Bank A and B. This should be enough to supply 5% of the UK’s electricity demand, the owners say, powering six million homes.

8 Artistic illustration of windmills at

Dogger Bank

Credit: Aibel

For the 3,500-tonne jacket foundation, four main piles and 9,500-tonne offshore substation topside, Heerema will perform offshore lifting to position the jacket foundation on the scour bed, using main piles to provide on-bottom stability.

The offshore substation will be lifted from a barge prior to the set-down on the jacket foundation. ”Inatalling sizeable offshore substations is core business for us and we are looking forward to working together on the preparation and installation of Dogger Bank C,” SAID Heerema’s wind director, Jeroen van Oosten.

Dogger Bank C is around 560 km2 in area, and almost 200km from shore.

SSE will lead the development and construction, and Equinor will operate the farm on completion for its predicted life of around 35 years.

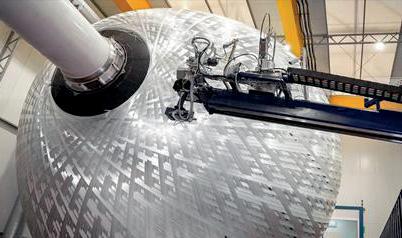

Two companies have entered into a partnership for the construction of a commercial scale Wave Energy Converter (WEC).

CorPower Ocean is currently fabricating its next generation C4 WEC, in collaboration with subsea composite specialist Diab in Sweden and Portugal.

Part of the flagship HiWave-5 Project, the WEC will ultimately join a four-system wave energy array, located off the coast of Aguçadoura in Portugal, forming one of the world’s first grid-connected wave farms.

“Diab’s technology is an ideal match for our composite hull structure, meeting all requirements with relevant certifications,” said Miguel Silva, managing director, CorPower Portugal.

“The Divinycell H sandwich composite is particularly well suited to WEC devices being designed specifically to withstand major fatigue, slamming and impact loads. Other important features include excellent adhesion strength and chemical resistance, with low water absorption and strong thermal insulation.”

Mobile factory

The decision to go commercial follows several months of process characterisation on quarter scale models. CorPower Ocean is now nearing completion of the first commercial scale hull at its Portuguese base in Viana do Castelo.

The site is also demonstrating the firm’s ‘mobile factory’ concept designed to enable

8 Diab’s Divinycell H sandwich composite is

particularly well suited to WEC devices

rapid roll-out of WEC hulls in port facilities near wave energy sites across the globe.

A key element to the hull’s sandwich structure involves the core material which provides strength and stiffness. Produced by Swedish firm Diab, the unique Divinycell H grade material brings a raft of benefits including high strength, durability and impact resistance combined with light weight and buoyancy performance properties.

During its latest partnership with CorPower Ocean, Diab provided structural engineering support, including analysis of loads and stresses exposed to the hull, to ensure the correct selection of core materials and laminates for the composite structure.

Lars-Magnus Efraimsson, Diab segment manager, said Divinycell H has a proven track record in virtually every application area where sandwich composites are employed, including the marine, land transportation, wind energy, civil engineering and general industrial markets.

“We are pleased to be expanding our portfolio in the subsea sector working with a fellow Swedish outfit and one of the leading wave energy developers,” he said.

“It’s always a pleasure to work with firms like CorPower Ocean which share our passion for innovation, as we continually explore new ways to improve our offering and make our clients’ products stronger, lighter and smarter.”

8 Real-time testing

Simulation system created for off shore wind sector

Two industry partners are joining together to create a new simulator system for the UK’s fl oating off shore wind sector.

Kongsberg Digital and the UK’s University of Plymouth are combining simulator technology and R&D expertise to provide offshore wind project teams and crew with facilities to verify, test and optimise floating offshore wind projects.

“This simulator could be a game-changer in the future deployment of floating offshore wind technology. As the sector expands, we need to develop innovative and effective ways of installing the technology in new and challenging environments,” said Professor Deborah Greaves OBE, Professor of Ocean Engineering and director of the Supergen Offshore Renewable Energy. Hub Kongsberg’s K-Sim DP will be used to simulate, test and optimise flaoting offshore wind projects. ”I believe our partnership with Kongsberg and the opportunity to learn from their experience and expertise can make significant strides in helping us to achieve that.”

Real-time simulation

Vital to this project is a state-of-the-art Kongsberg Dynamic Positioning (DP) simulator, which will soon be installed at the university’s campus.

The K-Sim DP simulator is built on the Kongsberg DP technology and will allow for thorough studies, mission planning, training and assessment of crew, where various challenging scenarios can be evaluated and optimised in a safe environment.

K-Sim DP will be used to simulate, test and optimise marine operations throughout the lifecycle of FLOW installations. This will provide key insights into solutions that will increase efficiency in both installations and operational maintenance, increasing safety and cost-effectiveness for the companies involved.

GANGWAY MANUFACTURER ENTERS SOV MARKET

A Dutch off shore access provider has sold its fi rst W-type gangway system to an off shore shipping company

The new Ampelmann system that has been sold to Olympic Off shore Wind AS marks an important turning point in the company’s commitment to the renewable energy sector.

“We are a global company and as such, it always excites us to broaden our horizon and bring together our experience as an offshore access provider to focus on what we consider to be new and exciting markets,” said Cinthia Mijares, business developer at Ampelmann.

“SOVs have become crucially important in the global renewable energy infrastructure and we want to contribute to the safety and efficiency of operations there.”

Tailor-made safety

The system will be permanently installed on the Olympic Orion in early 2023, when the vessel will complete its conversion from a Multi-Purpose Support Vessel (MPSV) into an Commissioning Service Operation Vessel (CSOV). Ampelmann’s W-type system satisfies a growing demand for safe, efficient and sustainable access solutions in the renewable energy market.

Tailor-made to individual vessels, the new system is electric, height adjustable and contains a lift and crane that can carry cargo and personnel. As it can compensate for vessel motions in sea states up to 3.5Hs, it can help increase the efficiency of maintenance operations on windfarms.

Alongside the new system, Ampelmann will provide operator training and 24/7 essential support through the company’s Operation Control Centre (OCC).

Until the W-type can be installed on the Olympic Orion, an E1000 has been temporarily fitted to the vessel so that it can continue its operations in the North Sea as a highly efficient ’Walk to Work’ vessel.

“We are pleased to continue our long-standing working relationship with Ampelmann.

“Olympic was one of the early movers in the offshore wind market and has been working more or less continuously on offshore wind projects for the last ten years,” said Marius Bergseth, COO Olympic.

“During this time, we have safely completed well over 200,000 personnel transfers via gangways without any incidents, and we look forward to continuing to expand our offerings to clients in this market going forward with the W-type onboard the Olympic Orion.”

8 Tailor-made to

individual vessels, the W-type is electric, height adjustable and contains a lift and crane that can carry cargo and personnel

UK sets new off shore wind targets

Trade body RenewableUK has welcomed the government’s new energy strategy.

A new target of 50GW offshore wind by 2030 will include up to 5GW of floating wind projects under the Energy Security Strategy published by the UK government in April 7.

Trade association RenewableUK welcomed the strategy, which sets targets to reduce the UK’s dependence on gas. By 2030, 95% of UK power should come from low-carbon sources, the policy says, with fossil fuel generation to shrink from the current 40% to just 5%.

The target will be achieved with more wind, solar and renewable hydrogen, says RenewableUK. To meet these looming deadlines, the government says it will reform the planning system to allow consents to be made within a year.

“The Prime Minister’s ambitious new strategy puts the rocket boosters under the UK’s transition to renewable energy and will cut consumer bills,” said RenewableUK’s Chief Executive Dan McGrail.

“The new targets mean that our world-leading offshore wind industry will do the heavy lifting in getting Britain permanently off the hook of gas power by boosting our nation’s home-grown energy supply. Reforms to speed up the planning system and how quickly we connect new offshore wind are essential to meet these new ambitions.

“Producing renewable hydrogen using electricity from wind will provide valuable flexibility to our future clean energy system, replacing gas in a wide variety of sectors like industry, transport and heating.”