11 minute read

Ingredients Antifreeze Proteins (Afp A Promising Ingredient in Food Applications

Antif reeze Proteins (AFP) A Promising Ingredient in Food A lic tions

— S. G. Dharini Sinehaa, R Chandrakala

Advertisement

Antifreeze proteins are novel protein substance which enables the various organism to survive in subzero environments. AFP has remarkable ability to depress the freezing point of water in a non-colligative way without altering its melting point and thus exhibits thermal hysteresis. Application of Antifreeze proteins as food preservative elevates the quality of frozen foods during freezing storage, transport, and thawing. Despite their high cost and requirement of expensive biotechnological techniques for commercial production, these proteins act as a potential ingredient with high activity even in low quantities.

Antifreeze Proteins (AFP) with an ice interacting activity that is found among a wide range of Psychrophilic organisms like fishes, plants, insects, bacteria, fungi, etc. AFP plays a vital role in supporting these organisms survive subzero temperatures. These proteins are responsible for inhibition of ice growth and ice re-crystallization by depressing the freezing point of the body. Therefore, its name is called to be Antifreeze proteins. It was first identified by DeVries in 1969 in the blood of fish living in areas where the sea froze. Several pioneering methods like Micro fluidic Cold-Finger Device with fluorescence microscopic technique were developed to investigate the mechanism of Antifreeze proteins. The properties of AFP are advantageous in the areas of biotechnology, cryopreservation and notably in food technology where the introduction of AFP enhances both the quality and nutritive value of food kept under cold storage conditions.

CLASSI CATION OF ANTI FREEZE PROT EINS

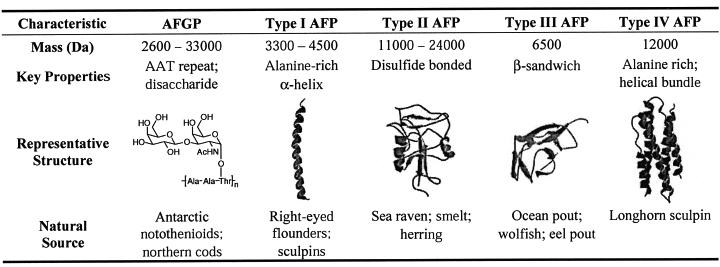

Fish AFP’s: The fish Antifreeze proteins are majorly classified into two groups: a) Antifreeze glycoproteins (AFGP) b) Antifreeze proteins (non-glycosylated) (AFP), also known as thermal hysteresis proteins or ice structuring proteins.

In terms of amino acid sequence, AFGP consists of a repetitive conserved sequence of (Ala-Ala-Thr) n, and the disaccharide β-D-galactosyl-(1fi3)-a-N

acetyl-D-galactosamine linked as glycoside to the hydroxyl oxygen of the Thr residues. Antifreeze proteins predominantly control the size, shape, and re-cystallization of ice. The AFGP and AFP make up 3.4% of the blood of many Antarctic fishes. AFP from fish is categorized as shown in Figure 1.

Insect AFP’s

Some of the insects like common yellow mealworm beetle (Tenebrio molitor, TmAFP), pyrochroid beetle (Dendroides Canadensis, DcATP), and spruce budworm (SbwAFP) are known to produce the most regularly structured proteins. AFP from insects is 10-100 times more active than AFP from fish due to which they are able to survive in much colder environment.

Plant AFP’s

They are found in a freeze-resistant plant in colder regions, for eg: Winter Rye, Carrot, etc. They have weaker thermal hysteresis activity

Fig. 1: Classification of AFP’s (Harding et al., 2003)

in AFPs; however, they have strong ice recrystallization inhibition activity.

MECHANIS M OF ACTION OF AFP’s

The extremely diverse AFP are isolated and characterized from different sources including fish, insects, plants, and microorganisms which are different in their structure, amino acid sequences, tertiary structure, etc. Each AFP is shaped in such a way that a significant proportion of its surface that is relatively flat can dock to ice in which the docking interaction is particular for that specific ice-binding surface. There are several factors responsible for the binding which includes surface-surface complementarity in which the contributions of hydrogen bonding is secondary to the van der Waals interactions. In addition, the ice-binding surface is hydrophobic which prevents it from getting solvated with ice. However, their working mechanism is not well understood.

APPLI CATIONS IN FOOD INDUSTRY

Antifreeze protein is intrinsically found in many foods consumed as part of the human diet. They are used to improve the quality of frozen foods by inhibiting recrystallization and maintain the smooth texture. AFP’s can also inhibit recrystallization during freezing, storage, transport, and thawing and in turn, retains the food texture by reducing cellular damage and minimizes the loss of nutrients by reducing drip. Since AFP’s acts extacellularly, they can be introduced in foods by direct mechanical methods like mixing and soaking. Proteins are responsible for inhibition of ice growth and ice re-crystallization by depressing the freezing point of the body. Therefore, its name is called to be Antifreeze proteins

However various studies developed gene transfer methods to introduce AFP’s into organisms at DNA level which may improve the texture and quality of frozen foods.

ROL E IN ICE CREAM

Ice cream industry suffers from a major problem of recrystallization caused by temperature fluctuations during storage destroying their texture and organoleptic property. This could be overcome by usage of AFP’s as recrystallization inhibitor of ice in ice cream resulting in a smoother texture with reformed tolerance to temperature fluctuations. AFP’s are considered as natural ice growth inhibitors in frozen dairy products. Except for gelatin, all the stabilizers were effective in retarding recrystallization in presence of ice-binding proteins which are evolved due to molecular interaction between the polysaccharides and proteins. The addition of ice-binding proteins to the ice cream aggregates the ice crystals into threedimensional network resulted in remarkably harder, highly brittle ice cream, enhanced shape, preserving capability, longer consumption time, etc. This also led to novel frozen desserts which are preferably harder and crystalline. The AFP expressing microorganism like Lactic acid bacteria are used for fermentation of milk to produce and store frozen yogurt.

ROL E IN FRO ZEN DOUGH

The quality of frozen bread dough is deteriorated during storage due to decrease in gluten cross-linking caused by ice recrystallization which lowers the gassing rate and dough strength. Treatment of frozen and frozen sweet dough with a Heterologous expression of type I antifreeze peptide GS-5 in baker’s yeast strains of Saccharomyces cerevisiae increases its freeze tolerance, gassing rate, and gas production. The application of carrot AFP to frozen dough retards the ice crystal growth, increases the retention capacity of dough and decreases the mortality of the yeast. Recombinant type I antifreeze protein (AFP), a food grade microorganism which is produced and secreted by Lactococcus lactic when introduced into frozen dough supports excellent fermentation capacity than untreated dough with same consumer acceptance.

ROL E IN FRO ZEN MEAT

Freezing and thawing of meat cause heavy damage due to the formation of large ice crystals intracellularly which bursts cell and leads to nutrition losses. Introduction of AFP’s in chilled meat causes no effect. However, AFP’s reduced the size of ice crystals and nutrition loss in frozen meat. These effects depend upon the concentration of AFP used and period of soaking but are independent of the sources. Injection of AFGP into muscle tissue 1 to 24 hours before slaughtering reduces the ice crystal size and drip loss. Frozen meat treated with rAFG significantly reduces protein loss, drip loss and improves the juiciness of the meat.

FUTUR E CHALL ENG ES FOR US E OF AFP

The isolation and purification processes of AFGP are time-consuming and expensive which makes it crucial for bulk production and commercial applications. In addition, the high cost of the AFP limits their capable use in foods. The removal of the lipolytic and proteolytic enzyme from the raw extract by heat treatment eventualize in the loss of AFP’s secondary structure. Therefore, the heat stability of these proteins is crucial.

Despite of all the challenges, antifreeze proteins (AFP’s) are the best novel ingredient for its promising applications and also for being more effective ingredient even in low amounts that in turn makes it cost-efficient. However, if there would be an increase in commercial production of isolated antifreeze proteins then its availability for the application may widen in the food industry. n

Authors: 1 S. G. Dharini Sinehaa, 2 R Chandrakala 1 B. Tech, 2 PhD Research Scholar, National Institute of Food Technology Entrepreneurship and Management, Kudli, Sonipat, Haryana E-mail: sinehaadharini@gmail.com, rchandrakala3892@gmail.com

Bühler Gi ves Leadi ng IQF Processor to Global Fruit And Vegetable Markets

As a knock-on effect of the worldwide Covid-19 lockdown, consumer demand for shelf-stable foods including frozen fruit and vegetables has soared. One company that has managed to successfully ride the wave of increased product demand is leading European frozen food producer: Fine Food.

The family-owned company based in Turkey has not ceased production or indeed any of its global export operations for a single day so far. The company attributes this resilience to the technological edge that it retains over its competitors, “We are the only business with Bühler’s SORTEX® FA series machines in Turkey and we believe that puts us in a very strong position in the market,” says Mehmet Berk Goztepe, Export Sales Representative at Fine Food.

Established in 1994, Fine Food has over 200 employees working across three factories in the Marmara region of Turkey; a new facility dedicated exclusively to the production of

Fine Food birds eye view

frozen French fries is currently under construction in the Emirdağ district. The company has a portfolio of approximately 20 Individually Quick Frozen (IQF) fruit and vegetable products, 12 of which are vegetables that are either grown or harvested on Fine Food’s own lands, or by contract farmers around the Yenişehir and Bursa provinces. A total of 70-80 million kilograms of sweetcorn, green beans, peas, spinach, strawberries and cherries are processed by the company every year.

Traditional yet innovative

Fine Food upholds a strong familyfocused ethos with members of the Goztepe family educated and exposed to all aspects of the business from a young age. Yet while the company may be traditional in its values, it is ahead of the curve when it comes to flexibility with urgent orders able to be processed in just one day. Such flexibility is made possible by Fine Food's use of the latest technologies.

Goztepe states, “With 11 sorters in total, our sorter infrastructure is far more advanced than others, something that not many Turkish processors can say.” One of the major contributors to Fine Food’s advanced sorting infrastructure is its trusted manufacturing partner Bühler who supplies the majority of the sorters for the company’s IQF products.

Frozen Berries in ice tray

A mutual alliance

The company began its relationship with Bühler by adding SORTEX E1D optical sorting machines to its portfolio. With the E1D machines, Fine Food is able to take advantage of high-resolution cameras and proprietary detection technologies to ensure maximum food safety.

The E1D’s double-sided detection of colour, shape and size, enables quick and easy removal of subtle to gross colour defects, insect damage, blemishes and Foreign Materials (FM) such as glass, plastic and stones that the company was previously struggling to consistently remove.

Strengthening the relationship

Following the exceptional performance and stability of the E1D machines, Fine Food decided to invest in Bühler’s latest technology to meet its growing IQF product capacity needs. With the SORTEX FA2 machine’s FDA approved adjustable 1200 mm chute, Fine Food is now able to process double the amount of product than before: 14 tonnes per hour. Goztepe notes, “In addition to the higher capacity with the FA2, I also like the improvement of the LED lighting functionality. "The lights stay bright throughout their entire lifecycle meaning there is no worry about having to frequently replace them.” Furthermore, the easy adaptability of the machines to suit Fine Food’s various IQF commodities allows for greater flexibility and control in the company’s day-to-day processing.

Exports and hygiene

The FA2 machines are specially

Frozen Berries

designed to meet stringent Western Europe and USA product safety requirements. Thus with 70% of their products exported to international markets including Europe, North America, the Balkans, the Middle East and East Asia, Fine Food trusts that its buyers’ needs will be satisfied and that a superior quality and consistent final product will always be delivered.

Cleaning the machines is easy thanks to the open and accessible design of the stainless steel frame and sloped surfaces. With virtually no product build-up, there is a very low risk of contamination. This, Goztepe says, “keeps us feeling confident that we're always adhering to the toughest hygiene and food safety standards.”

A SORT EX® PolarVision™ edge

The FA2 machines are also equipped with Bühler’s renowned SORTEX PolarVision detection system which combines two pioneering technologies for unmatched FM removal: PolarCam™ technology and high definition InGaAsHD cameras. Goztepe says, “The SORTEX PolarVision technology came as a huge advantage for us for FM removal, particularly in the case of snails.

“It has also proved very useful in detecting any Extraneous Vegetable Matter (EVM) and colour differences. We now eagerly await the upcoming wet season this year as that is when we expect to find the most EVM in peas, so we’ll be able to see the full strength of the SORTEX PolarVision technology!”

Customer service

Gurhan Nergizoglu, Sales Manager

SORTEX F

for Bühler’s local Turkish sales agent Atomika states, “One of the main reasons Fine Food opted for the FA2 was to be able to detect and remove any snails, black plastics and FM, for this reason our SORTEX PolarVision technology really appealed to them.

“They needed to ensure the best quality within their national and export markets.” Goztepe adds, “With Atomika everything runs quickly and smoothly, we never have any issues. Personally and ethically we really enjoy working with them.”

He goes on to add that Fine Food chose to install its “very easy and straightforward to use” SORTEX E1D and FA2 machines after the freezing tunnel. The optical sorters were integrated by Bühler’s Service Engineers and now Goztepe is able to say with pride that, “99% of the time our machines only need to sort a batch once.” With the E1D and FA2 machines, the company rests assured that its final products will meet the highest international quality standards without the need for multiple sorts, reducing energy consumption and saving time.

The future is bright

Goztepe concludes by mentioning that if the company has scope for future investment it will be returning to Bühler. “We only use the world’s best brands. The Fine Food philosophy is that if we are happy with a particular manufacturer we will preserve that relationship and that is definitely true of our partnership with Bühler.” n