3 minute read

Best accolades for Valtra’s Beast

from ProAgri BNZ 44

by ProAgri

Valtra’s rewarded Q Series was released last year

Valtra celebrates another achievement as their Q Series ‘Beast’ received the prestigious Red Dot Award for Product Design. The announcement comes less than six months after their newest tractor, the Q Series was released. The new series suits the higher horsepower segment.

Advertisement

The Q Series was released in September 2022, and quickly garnered industry attention, picking up the Farm Machine 2023 Jury Award at the SIMA show in Paris, last November. The Farm Machine jury praised the Q Series for its agricultural contractor focused approach.

At 171 to 227,5 kW (230 to 305 hp), the Q Series fills the gap between Valtra’s T Series and their S Series. In test drives, customers have praised the Q Series’ smooth CVT transmission, manoeuvrability, and high level of visibility for such a high-horsepower tractor. To achieve this, careful consideration has been given to the design of the Q Series.

Industrial Design and User Experience Department Lead, Kimmo Wihinen, explains that the best tractor experience comes from listening to the customer: “Customers have been asking for a bigger T Series. We have delivered a completely new tractor. Large farms and agricultural contractors need an efficient higher horsepower tractor but with good manoeuvrability and visibility. Everything from the easy access via the aluminium steps, the all-new powerful integrated front work lights, cab comfort, new roof design, and easy-touse, fully integrated technology via the SmartTouch user interface, responds to customer feedback. Everything is designed to make the Q Series a comfortable, and well-equipped tractor. It is the best tractor we have ever designed and built here in Suolahti in Finland. We are very happy that the Q Series continues Valtra’s history of winning Red Dot Design Awards.”

Valtra’s previous successes with Red Dot Awards included an award for the T Series in 2016, an Honourable Mention for the N Series in 2017, a win for the A Series in 2018, for the G Series in 2021, and, more recently, a Red Dot Award for the N Series in 2022.

Valtra’s Q Series will be on the road heading to various locations across Europe as part of Valtra’s SmartTour 2023. (world-agritech.com)

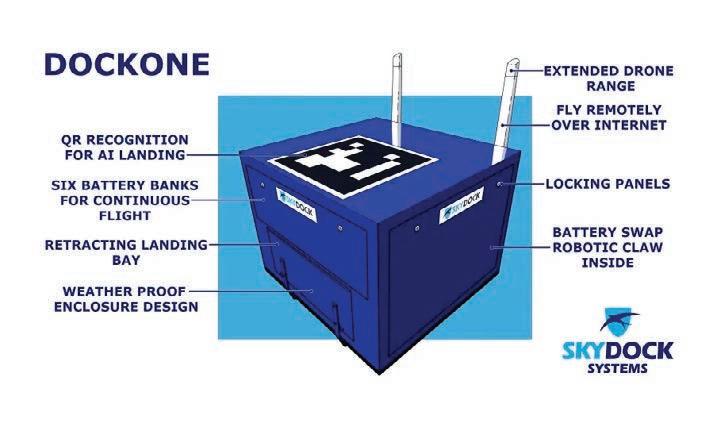

Automated recharging solution for drones

Drones can be very useful tools for farm security and crop protection, but short work times with manual intervention due to limited battery power is problematic. Dock-One is Skydock Systems’ automatic drone battery swapping and mission planning solution for DJI Mavic; with other drones to follow shortly.

Dock-one is an affordable drone battery swapping station developed in South Africa for the local and international market.

It allows you to fly drone missions 24/7 in an automated fashion.

The docking station design was incubated by Roelf Diedericks and Wikus Combrinck during the COVID-19 pandemic, when a family farm near Mabalingwe Game Reserve in the Limpopo province of South Africa was struck by a spate of night-time burglaries in the surrounding lodges. Manual patrols by the reserve, using a thermal drone, resulted in several arrests, and served as a deterrent for would-be criminals reducing security incidents by 99%.

The challenge with staff needed for manual drone surveillance and manual battery swapping is solved by the DockOne docking station.

Paired with the DJI Mavic 2 Enterprise drone, DockOne allows you to automatically patrol day and night, and using the drone’s accessories such as the spotlight, or loudspeaker, nefarious activities can be stopped in its tracks.

Drones used for crop monitoring and protection in orchards will also be able to continue with their work non-stop.

Using the SkyDock/Flight Now system, you can create automated missions and monitor the drone from a centralised location over the internet.

The DockOne solution comprises three components, the DockOne docking station, FlytNow mission planning and remote-control software, and the DJI Mavic 2 Enterprise drone.

DockOne quick info

• Quick battery swapping docking station.

• 5 batteries on constant charge.

• Weather resistant enclosure, 200W thermo-electric heating and cooling.

• Built-in camera for remote monitoring.

• External LED landing light support.

• 2 x 12v back-up batteries for safe landing in power-outage situations.

• Automated precision landing.

• Dual extended range drone antennas (up to 10 km)

• Built-in 4G/LTE, WiFi, or Ethernet Internet router.

• Remotely accessible dashboard.

• Dimensions (H x W x Depth) : 690mm x 970mm x 920mm

• Weight: 70kg

• Material: Mild steel, powder coated.

SkyDock Systems is a division of ByteHeavy Industries (Pty) Ltd, a South African based software and robotics engineering firm. For more information, visit https://skydock.systems/ dock-one/.