9 minute read

Nostalgia

from Wavelength #73

Welcome to yet another Nostalgia article! We hope you enjoy the journey into the past and that it motivates you to recall your experiences and share them amongst your colleagues in order for them to live on. In this edition, we will start off with the engine room and take a look at some photos of our team of technical superintendents on board during dry dock repairs back in the day. Then we will take a look at one of our previous vessels in the Company’s fleet, which justifies the motto “impossible is nothing”.

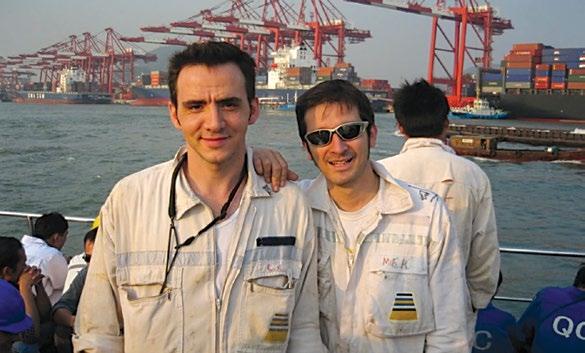

So let’s start off with some photos taken during 2007. These are of the dry dock/ conversion to double hull carried out on board the m/t CE-Ulsan at Shekou, China. Shown right are superintendent engineers, Mr. Michalis Maritsas and Mr. Christos Kartsonas, in their early years with the Company on the morning service boat, excited to be participating in the dry dock works of the CE-Ulsan.

Advertisement

The CE-Ulsan was an aframax tanker, originally 115k deadweight, built in Hyundai Heavy Industries, Korea in 1990. She was one of the largest aframaxes of her era. She joined our fleet in 2004 and was sold in 2012. In the meantime, she was converted to a double-hull tanker with a reduced deadweight of 107k.

They may look like the ghostbusters but in fact, they are the "repair-busters", our team of superintendents, Mr. Yannis Fassoulis (ex super/nt eng), Mr. Christos Kartsonas (super/nt eng), Mr. Christos Chatzigiaksoglou (super/nt eng) and Mr. Paul Birleanu (super/nt eng).

Below, the director of Marine Operations, Mr Michalis Kapsorrachis, Marine superintendent, Captain Yannis Papageorgiou and superintendent engineer, Mr. Christos Kartsonas, are working in adverse weather conditions but still enthusiastic.

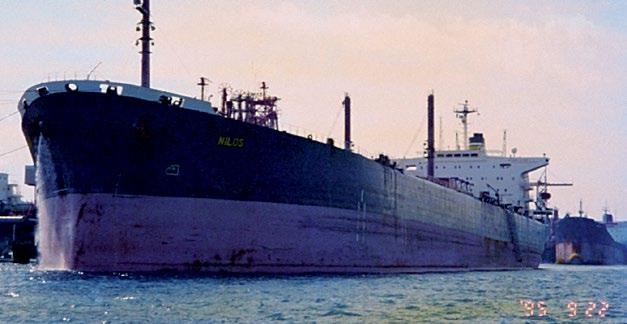

Moving on,let us take a closer look at m/t Nilos, a 89k dwt single hull aframax tanker, built in Imabari, Japan in 1981. Bonding over lunch after a hard day’s work! From left to right : Mr. Paul Birleanu (super/nt eng), Mr. Yannis Fassoulis (ex super/nt eng), Mr. Antonio Magtagol (C/E), Mr. Andaya Zosimo (ex C/E), Mr. Christos Kartsonas (super/nt eng), Captain Andaya Emeterio (ex Capt, the most senior Master of the Company at the time and the first Philippino Master to take command of a Company vessel - M/T APNOIA in 1996), 2/E, Mr. Antonio Magtangol (C/O) and Mr. Mei – Ship Repair Manager.

She was sold and converted to a semi-submersible heavy load carrier in 2006, and is still active today at the age of 39!

Let’s see if you can guess who this charismatic, young, safety cultured girl is.

Find the answer on page 19.

Finally, don’t forget that we depend on your participation to provide past photos of your adventures at sea! So, keep sharing your collection of photographs by e-mail to contact@ wavelength.gr. Make sure you add a note for each photo, stating the name of the ship, date, location and the names of any seafarers in the photo. Looking forward to seeing you in the editions to come!

Calm seas and safe travels,

Eleftheria Lemontzoglou, Operator

Sedov sets off on trans-arctic voyage

The 99-year-old four-masted steel bark Sedov is sailing home by an unusual route. She is sailing North from Vladivostok and transiting the Arctic by the Northern Sea Route to reach her home port of Kaliningrad. Crossing the Arctic will be the culmination of a grand voyage of more than 25,000 nautical miles sailed by the Sedov since November 1, 2019. “Following a detailed study of possible alternatives for the bark’s continued sailing, we consider it relevant to propose that the Sedov completes its expedition with a voyage across the Northern Sea Route from the east to west,” said Ilya Shestyakov, the head of Russia’s Federal Agency for Fishery, which operated the ship. “We believe that such a voyage will have a great symbolic and practical effect.” The ship is expected to reach its homeport of Kaliningrad on November 15 this year. On its Arctic expedition, the vessel is due to visit the ports of Pevek, Sabetta, and Murmansk. It is also expected to make a halt in the archipelago of Novaya Zemlya. An icebreaker will accompany the ship to ensure its safety during its voyage through the Arctic. Sedov was built as the Magdalene Vinnen II in 1921. She is one of the largest traditional sailing ships in operation. Today, Sedov is a sail training vessel, training cadets from the universities of Kaliningrad, Saint Petersburg, and Astrakhan, Russia.

Submitted by Cmdr Nicholas Iliopoulos. Source: Old Salt Blog

Food Culture Moussaka

It is widely believed that Moussaka originated as a result of Arabs bringing the eggplant/aubergine to the Mediterranean region. It was a significant introduction, not only because it led to the dish that has become synonymous with Greek cuisine but also because eggplants have a wide variety of nutritional benefits. Firstly, they are high in fibre and low in calories. Secondly, they contain important minerals in fair quantities such as manganese, potassium and iron as well as traces of magnesium and copper. Thirdly, they possess vitamins K, C and B6 together with high levels of antioxidants. Initially, the dish appeared in Greece in the form of a baked casserole, and it continued to be served in this way for about 100 years. Then, in the 1920s, Nikos Tselementes, a Greek chef from Sifnos who has to become known as the moderniser of Greek cuisine, made some changes to the dish. These changes allowed Greek cuisine to embark on its own path without being constrained by Turkish influences. Moussaka became strongly layered, allowing it to be served in distinct portions rather than as a kind of ‘stew’. Although there are several layers, there are two distinct sections: the bottom part centred around the sliced eggplant and the topping consisting of béchamel. Ingredients include lamb or a mixture of lamb and beef mince, onion, garlic, oregano, mint, bayleaf, cinnamon, chopped tomatoes, salt, olive oil and, of course, eggplants. To cater for vegetarians, chefs can replace the meat with a mushroom-based sauce. As regards the béchamel, this is made from unsalted butter, flour, milk, salt, egg yolks and cheese. Moussaka, served in its modern form thanks to chef Nikos Tselementes, may be regarded as a symbol of Greek independence from occupying forces. It may also be viewed as a Greek dish that has been elevated to international cuisine with award-winning restaurants in such countries as the USA, Australia, Singapore, Israel and Hungary serving it to discerning diners, and onboard cooks serving it to hungry seafarers on the high seas.

Traditional Greek Moussaka Courtesy of: www.mygreekdish.com

Sources: www.theculturetrip.com, www.tasteatlas.com, www.bonapetit.com, www.onedishcloser.com

Culture Corner Dhow Building in Gujarat

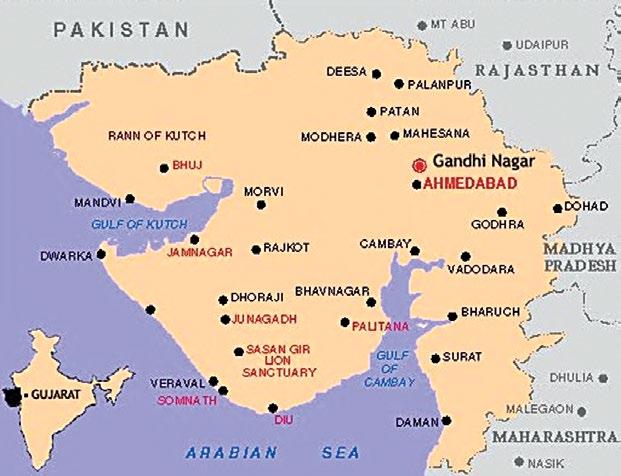

Mandvi, which was founded by Rao Khengarji I, King of Kutch, in the late sixteenth century, is now the dhow building centre in India. At the time of its establishment, Mandvi was ideally located to become a thriving port. Facing the Sea of Oman on the Gulf of Kutch, Mandvi lay on the intersection of the spice and camel caravan routes. Therefore, it was inevitable that its access to West Asia and Africa together with its proximity to these two great trade routes would lead Mandvi to gain prominence as a maritime link. As such, Mandvi was home to a large majority whose livelihoods were dependent on mercantile, sailing and boat-building activities.

Map showing Mandvi on the Gulf of Kutch and its proximity to the Arabian Sea

By all accounts, Mandvi became more and more prosperous as both exports and imports increased. Indeed, by the eighteenth century, Mandvi merchants operated about 400 vessels that sailed on trade routes with East Africa, the Persian Gulf and the Malabar Coast in India. The burgeoning maritime trade bode well for the boatbuilding activities that took place on the banks of the River Rukmavatu, which flows south through Western Gujarat. Nowadays, however, Mandvi’s importance as a port has diminished greatly, but its 400-year-old dhow building tradition lives on despite the order books being much thinner. Building materials and methods have changed somewhat over the centuries, yet there are some practices that have not altered. First and foremost, the basic construction material, wood, is no longer the same. Once sourced locally, it is now imported from Malaysia. More specifically, the timber used nowadays is ‘sal’ wood (Shorea robusta), which is an ideal choice due to its durability and water resistance. The first step in any dhow building project, which is overseen by a senior craftsman and requires some 30 labourers working for around two years to complete, is the laying of a single curved beam of approximately 20m in length. Around the base of the hull or spine, bent ribs are attached. To these, long planks are fixed from stem to stem using steel bolts. The woodwork is often accomplished by cutting, planing, chiselling and drilling by hand, although power tools can be used whenever necessary. As regards the steel bolts, these have replaced the original hand-forged iron spikes that once held the ships together. Making the dhows watertight is still a traditional process in which thin cotton cord is soaked in oil before being wedged into the seams between the planks with a hammer and chisel.

Dhow under construction at Mandvi. Source: www.wikipedia.org

A worker sweeps up wood shavings in the hull of a ship under construction. To hold the vessel together, workers drill holes through the planks and timbers, and then secure the wood using long steel bolts.

Source: www.caravanmagazine.in

The dhows built at Mandvi range in capacity from 300 to 1500 tonnes with the majority falling in the higher categories. The largest can reach four storeys in height and require a crew of around thirty to operate them. Unlike the dhows of the past that relied on their lateen sails for power, modern ones are towed out at high tide into the Gulf of Kutch and then to dockyards on the Arabian Penninsula to be fitted with diesel engines and registered by the buyer. So far, boatbuilding at Mandvi has survived many challenges. Fortunately, today there are still buyers, many of whom are from Dubai, willing to maintain demand. Additionally, the traditional building methods still used in the construction of dhows have attracted a few tourists who wish to witness firsthand, skills that have been handed down for generations and that continue to provide livelihoods for the artisans of Mandvi.

Sources: www.caravanmagazine.in, www.visura.co, www.gujarat-travels.com www.economictimesofindia.com, www.travelswithsheila.com