3 minute read

Restoring fire protection integrity in

Restoring fre protection integrity in shipbuilding

Vitribond Marine covering a speaker opening.

Advertisement

A BRIEF HISTORY OF CULIMETA TEACHES US THAT THE COMPANY HAS BEEN ESTABLISHED BACK IN 1926 IN THE HAGUE BY HENRI CUYLITS AS A COMMERCIAL ENTERPRISE FOR METALS. CULIMETA WAS CONTINUED BY HIS SON ALFONS Cuylits with the foundaton of a sole proprietorship in Monheim in 1958 for the import and export of thermalelectric insulatng hoses and textle glass fbre gaskets. The present-day company name of Culimeta originates from 1926: Henri Cuylits Metallhandel.

ALL PHOTOS COURTESY OF CULIMETA.

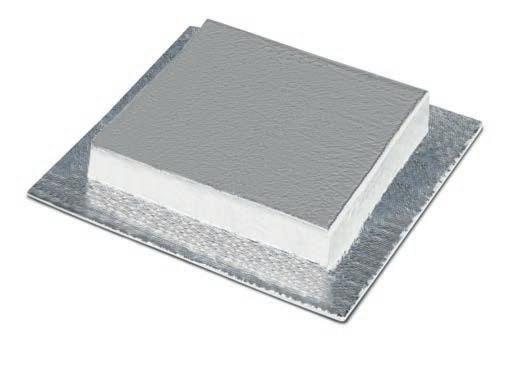

The adhesive used in Vitribond Marine has a cooling effect, making it a lot lighter, thinner, and easier to handle and install.

The company, based in Bersenbrück, Germany, is specialised in all kinds of thermal, acoustc and electrical insulaton. Most of these products are related to glass fbre, which is the main raw material that the company utlises. Some of the manufactured products include yarns and plied yarns made from e-glass, gaskets for freplaces and industrial appliances, insulaton sleeves, exhaust insulaton for the automotve sector, fre protectve products for constructon, shipbuilding, and e-mobility, fexible fre protecton products, exhaust silencer insulatng materials, as well as pipe insulaton systems.

Complex systems require intelligent solutions

Fire protecton division Culimeta Innobra provides the tools required to enhance professional knowledge of fre protecton. The division undertakes precise analyses of requirements and legal regulatons, factoring in cost efectveness and process

Vitribond marine coverage for application on downlights, loudspeakers, hinged frames, inspection openings, and many other.

• Light weight • Components are safe for humans • Easy to assemble • Suitable for downlights, loudspeakers, hinged frames, and inspecton openings • Low installaton height • Can be cut and adapted using standard tools (industrial scissors)

Technical product information

• Area weight: 900g/m² ± 15% • Width: 1,000mm ± 10mm • Thickness: 5.0mm ± 2mm • Roll length: 40m • VitriBond Marine is available in rolls • Bonding of the joints and fxing to the elements with aluminum adhesive tape certfed module B

reliability to develop customised solutons which will give its customers the ultmate compettve edge in their sector. In this way, the division develops efectve fre protecton systems individually customised to certain specifcatons, all designed to meet the challenges of tomorrow. Culimeta Innobra products are used in the constructon industry, for facades, windows, basement and ceiling systems, thermal and acoustc insulaton, trade fair constructon and shop-ftng walling insulaton systems, partton walls, and printed surfaces. The fre protecton division ofers a full-service package, startng with taking stock of development requirements to manufacturing fre protecton products.

Vitribond Marine

Passenger cabins on a cruise ship are typically made of sandwich panels (metal panels on both sides with a mineral wool core). These panels require a certain fre ratng, so they can withstand a fre in the cabin and contain it to gain tme to evacuate the ship or extnguish the fre. When the panels are penetrated, for example for sockets, speakers, or light fxtures, the fre protecton ratng is void. To regain the ratng, the openings should be closed with a new hood that has to be tested together with the cabin beforehand. Currently, these hoods typically consist of a tailored litle box made of mineral wool (handmade). Vitribond Marine is especially developed to replace this. The adhesive used in Vitribond Marine has a cooling efect, making it a lot

Speaker opening after fre exposure when covered with Vitribond Marine.

lighter, thinner, and easier to handle and install. VitriBond Marine is a non-fammable product for restoring the fre protecton integrity of wall and ceiling elements in shipbuilding. Due to the endothermic efect of the non-organic adhesive in the product structure, VitriBond Marine is ideally suited as a fre protecton cover for openings and fxtures in vertcal and horizontal surfaces onboard ships. VitriBond Marine is module B certfed and has been successfully certfed as fre resistance class B15 for covering downlights and speakers.