5 minute read

New generaton of ocean mining assets

New generation of ocean mining assets

BIG-BJARKE INGELS GROUP HAS COLLABORATED WITH THE METALS COMPANY TO REMAKE CONVENTIONAL METAL PRODUCTION FOR THE 21ST CENTURY AS SOCIETY EMBARKS ON THE TRANSITION TO A NET-ZERO-CARBON FUTURE.

Advertisement

The Metals Company’s challenge with BIG was to bring innovatve, whole-systems design to the industrial components needed to supply the world with critcal batery metals from polymetallic nodules (fst-sized rocks containing batery-grade nickel, cobalt, copper and manganese), while reimagining the nexus of industry and community.

Minimise seafoor compaction

BIG delivered an integrated suite of assets that work together to lif nodules of the seafoor and up to a purpose-built producton vessel, transfer them to a hydrodynamic shutle carrier, and onward to a metallurgical plant designed to transform an urban port site into a batery materials innovaton and community hub, set within a regeneratve coastal landscape. “To collect the nodules, we have designed a lighttouch, robotc collector vehicle that aims a jet of seawater across the tops of the rocks to gently pry them from the sediment. Part of our design for future collectors includes a buoyant, hydrodynamic shell with an extended lip to minimise seafoor compacton and reduce and redirect the dust plume kicked up during nodule collecton”, says Daniel Sundlin, Partner at BIG and partner in charge of the collaboraton with The Metals Company.

Compressed air bubbles

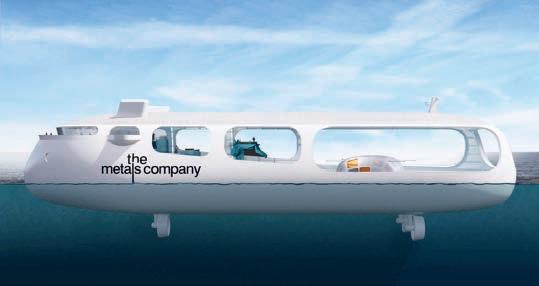

The Metals Company’s frst-generaton collector vehicle has been engineered and is currently being built by Allseas in the Netherlands to be deployed for testng early next year. While The Metals Company’s frst producton vessel is a deep-water drillship repurposed by Allseas to enable pilot nodule collecton, BIG’s next generaton vessel design is central to The Metals Company’s plans to scale to a feet of ten producton vessels, enabling the provision of over 40t million of batery metals by 2050, enough to produce 280 million electric vehicles; a quarter of the global passenger car feet. Nodules are transported through a fexible hose at the top of the collector vehicle to a rigid riser pipe where they are lifed on compressed air bubbles 4km up to the surface producton vessel, a 216m-long ship that runs on carbon-neutral electrofuels, with a sunken deck that is covered with photovoltaic solar panels. The streamlined design of the producton vessel is driven by functonality. Equipment for nodule collecton is strategically packed in the hull to minimise the size of the vessel and maximise operatonal efciency.

Lowering carbon foot print

At scale, each producton vessel would operate multple collectors with additonal maintenance capacity provided by a support

BIG designed a robotic collector to minimise disturbance while gathering polymetallic nodules from the abyssal seafoor. Directing a jet of seawater across the tops of the nodules, the collector gently frees them from sediment and lifts them on compressed air bubbles to a production vessel at the surface. BIG designed the production vessel as a 216-meter ship that runs on carbon-neutral electrofuels. Its sunken deck will be covered with photovoltaic solar panels.

vessel with a moon pool for deploying and retrieving collector vehicles. At operatons, nodules will be transferred from the producton vessels to shutle carriers, whose X-bow design was chosen by BIG to deliver hyper-efcient, hydrodynamic ships to further assist The Metals Company in lowering the carbon footprint of its batery metals. Once at port, the nodules are ofoaded onto a conveyor and into a portside processing plant – designed by BIG as a sustainable, performatve and social campus in a regeneratve landscape that turns conventonal metallurgy on its head. “Deep-water ports around the world are ofen degraded ecosystems unwelcoming to local communites. We asked BIG to reimagine what a metals-processing facility could be, to have it integrate with – even remediate – the urban coastal environment,” says The Metals Company Chairman and CEO, Gerard Barron. “The result is a breath-taking innovaton complex that will transform an industrial port into a community-based hub for the electric vehicle revoluton.”

Entire new industry

“The global energy system needs to undergo its most profound change in centuries to realise a world run exclusively on renewable sources. If the ongoing research and studies conclude that harvestng minerals from the seabed can be done in an environmentally and socially responsible way, we will not only be able to accelerate the green transiton but give form to an entrely new industry that will create a sustainable circular metals economy for future

The Metals Company requires processing facilities to offoad nodules near deep-water ports. These are typically degraded, brownfeld sites. BIG designed a circular, zero-solid-waste metallurgical plant to contain both pyrometallurgical processing and hydrometallurgical refning steps in a single facility. This effort will transform its urban port site into a battery materials innovation and community hub set within a regenerative coastal landscape.

generatons”, adds Founder and Creatve Director in BIG-Bjarke Ingels Group, Bjarke Ingels. BIG designed The Metals Company’s circular, zero-solid-waste metallurgical plant to contain pyrometallurgical processing and hydrometallurgical refning steps, stockpiles, and product storage alongside ofces, visitor-centric experiences, and an innovaton centre to te products into the EV supply chain.

Multiple facilities

The company envisions multple facilites spread across three contnents and a number of brownfeld sites are currently under consideraton. These plants would in tme be retooled to recycle batery cathodes at end-of-life, closing the loop on the batery metals supply chain. “The world is characterised by a mindset that divides the world into front of house and back of house. The front of house is carefully designed in the form of beautful facades and lush parks, leaving the back of house as purely utlitarian and logistcal lefovers in the form of parking lots and warehouses. With The Metals Company, we are designing a human made ecosystem channelling the fow of resources with the care and atenton conventonally reserved for the front of house. A next-generaton materials industry,” concludes Mr Ingels.

i. metals.co