4 minute read

Maintaining maritime infrastructures

Maintaining key maritime infrastructures TMS Maritime has worked on two Whitby Piers and the Isle of Man Sea Terminal to ensure that they continue to deliver. Words: Peter Dunwell

The jobs for which clients use diving businesses and divers are many. Here are just a coupole of recent cases from the files of ADC member ‘TMS Maritime’.

WHITBY PIERS

In Collaboration with Balfour Beatty, TMS not only delivered but exceeded expectations for this six months, £2.5million project; completing repairs to East Pier and West Pier in the Yorkshire coast town of Whitby ahead of schedule for Scarborough Council.

The scheme resulted in the upgrading of the aged piers’ structures to improve their condition. There were essentially two aspects to the works involved. Firstly, stabilising the external sandstone facing blocks of the piers, this involved drilling out damaged sandstone blocks then replacement from the original source quarry at Eskdale. These replacement blocks were skilfully dressed by the team to match the existing structure and, once placed, the voids behind were reinforced and concrete

weather and the coastal environment.

The project received significant funding from the European Structural and Investment Funds Growth Programme. The Ministry of Housing, Communities and Local Government and the Department for Work and Pensions are the managing authorities for European Regional Development Fund and European Social Fund funding through the Growth Programme, funds established by the European Union to help local areas stimulate their economic development. Funding was also secured from: the Environment Agency; York, North Yorkshire and East Riding Local Enterprise Partnership; North Yorkshire County Council and Scarborough Borough Council.

ISLE OF MAN SEA TERMINAL

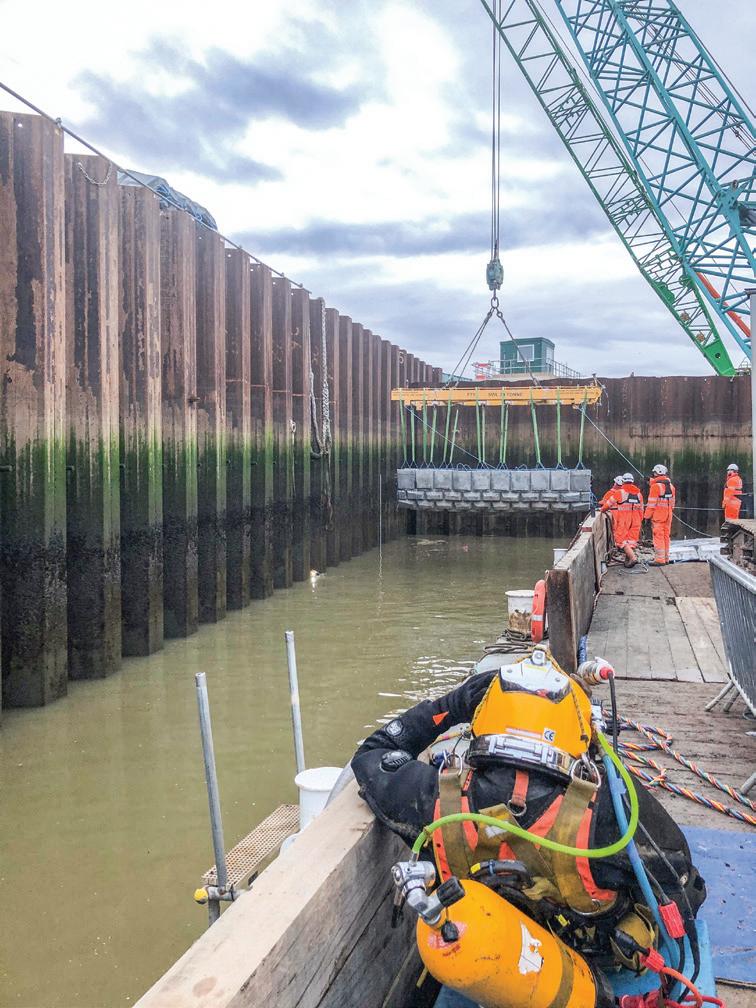

In August 2018, Teignmouth Maritime Services were contracted by BAM Nuttall to carry out various scopes of work at the Sea Terminal in Douglas Harbour, Isle of Man. In a nine month, £1.5million project, these consisted of scour protection to the two Ro Ro ferry berths, linkspan hoist tower piles life extension (consisting of repair sleeve and denso sea shield), installing a new fender pile and repairs to previously damaged piles; and sea shield work to the three walkway dolphins situated within Douglas Harbour.

filled. Secondly concrete was placed below the water line creating a reinforced scour protection, protecting the base of the piers for many decades to come.

The delivery of the works were complex in nature with access requiring innovative thinking, dive teams, and bespoke access equipment. Working closely with the client to ensure schedule, quality, budget and public relations were, maintained; achieving full potential in order to reflect well on all those involved, TMS experience in all things maritime proved invaluable.

The works, in addition to havingto be carried out in difficult working conditions, had extreme access restrictions through very narrow streets and foreshores. These problems were significantly eased by TMS’s marine capability and experience which further mitigated risk associated with the unpredictable influences of

In order to protect the two berths, the design was to install Proserve pumped concrete mattresses to provide scour protection totalling 1150m 2 over both berths. Following the removal of debris and preparing the sea-bed, layers of 2 tonne Kyowa rock bags (approx. 1000 in number) were installed and guided into the correct position by divers to the edge of the scour underneath the linkspan. This layer created an even surface to lay the concrete mattresses. Once all the mattresses had been installed they were then pumped with concrete and additional 2 Ton rock bags were installed along all edges to stop future scour occurring underneath the mattress.

Three of the eight linkspan piles required repair works due to propeller wash from vessels combined with ALWC (accelerated low water corrosion) which had caused the piles to thin. These three piles were firstly cleared of debris, silt and seabed inside the piles and then repair sleeves were installed prior to pumping with concrete: all piles were wrapped with a Denso SeaShield system.

The fender pile at the end of the pier had already been removed, TMS were therefore required to socket the new pile into the original pile. Firstly, the pile stub that remained had to be cut using BROCCO (underwater cutting equipment) below the remaining damaged part

of the pile where the pile had been bent over; to allow enough circular room for the new pile to be fitted. The internal area of the pile stub was then excavated to a depth of 1.3m below seabed, once secure the pile was pumped full of concrete which allowed the fender pile sleeve to be installed over the pile for the fender panel installation.